I would not suggest following ANY advice from ARW about injection moulding. He clearly has no clue about building a safe to operate moulding setup or how to operate it.

The Gingery machine has been built many times and does work for very small parts – but a common complaint from builders/users is lack of part to part dimension and strength control.

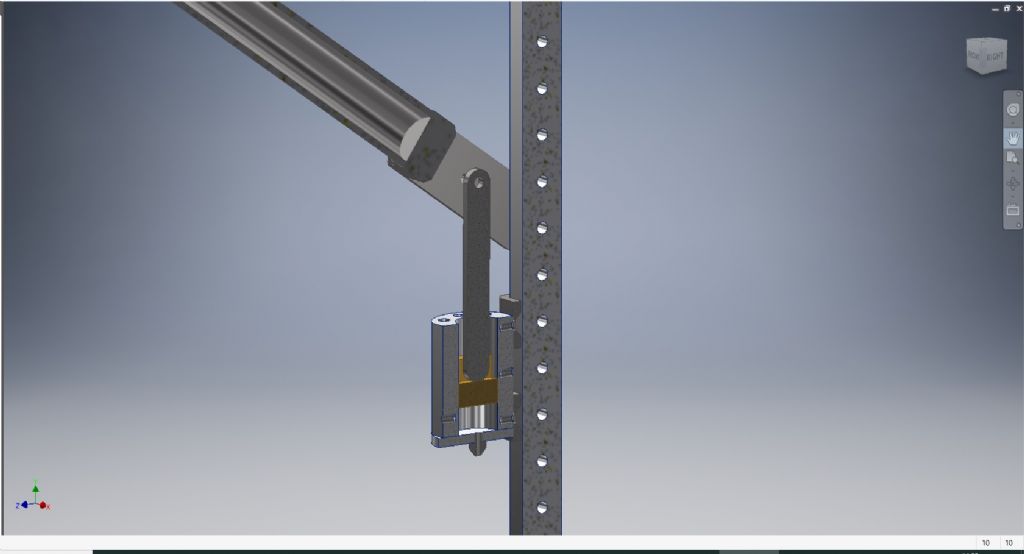

One key aspect of injection moulding machines that people seem to miss is that the mould needs consistent and even clamp force across the whole mould, and the mould and injection barrel need to be kept aligned. Setting a mould loose on the beam of a hydraulic jack press and having the injector cocked at a strange angle under huge force is asking for an accident.

To calculate the clamp force needed, to need to find the projected (plan view) area of the part then multiply by your max possible injection force. Multiply that number by two or three and that is how much clamp force you need as a minimum. If your planned parts are large you will be surprised at the forces involved.

For any consistency of strength and density in your finished parts, barrel temp, mould temp, injection pressure, heating time, injection time, cooling time (at a minimum) will need to be controlled. Most resins do not do well sitting in a hot barrel between shots either (called "holdup time". Feed resin, heat and shoot, repeat, with no wasted time, with carefully controlled parameters, is the name of the game for consistent parts.

If I were you I would look into making a mould or moulds to standard industrial practice and handing it to an injection moulder to run in a commercial injection moulding press. Find and talk to a moulder and he will steer you to what mould dimensions and construction will run in their presses. The moulds are where the art is. Think of it as if you wanted to make turned parts – would you build a lathe or use a ready made one? Good presses are already out there at injection moulding firms. Fewer such firms now in UK and North America than there used to be, but still plenty around.

Just my opinion from many years in industry involved with plastics design and moulding.

Edited By Jeff Dayman on 02/11/2020 15:07:47

Chris Evans 6.