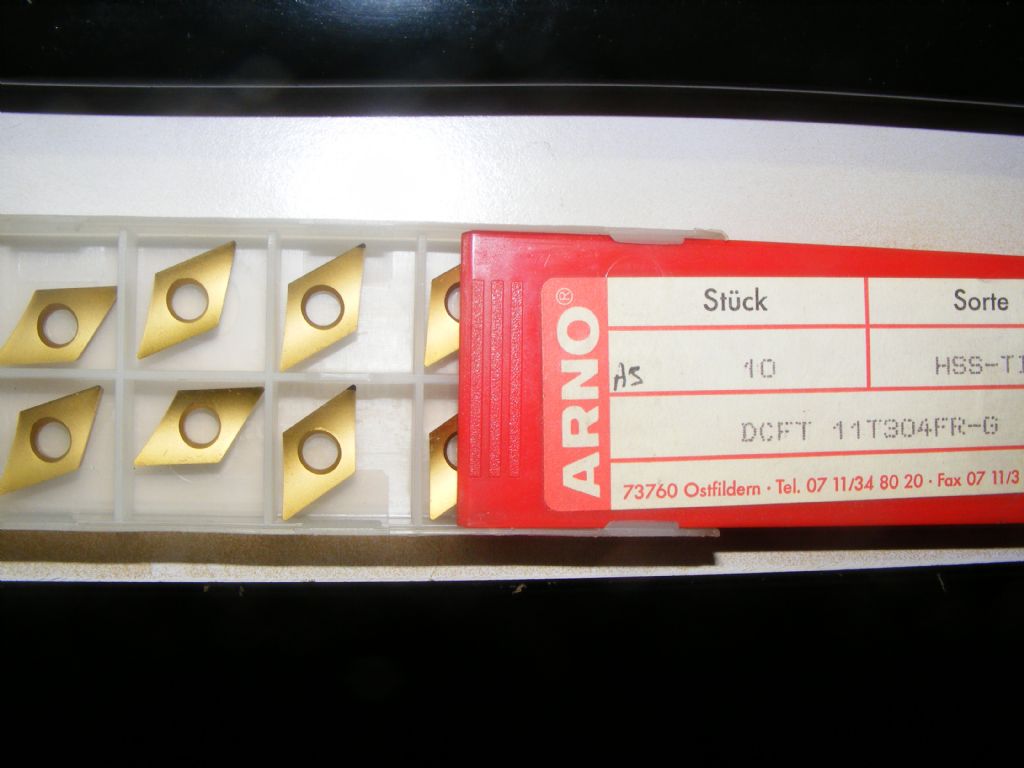

First it depends upon the insert. There are many obsolete inserts around for which holders are no longer available. Even if the insert isn't obsolete you then need to consider tool holder size. Most modern insert holders start at 16mm and go upwards. Smaller 8mm and 12mm holders are available, but are less common. To make any sort of sensible comment we really need to see a picture of the inserts.

The other issue with inserts is that, with common low carbon steels, they really need to be run fairly fast and hard in terms of feedrates to get a good finish.

In short I agree with Norman, I don't think the ML1 is likely to have the rigidity, spindle speed or horsepower to make use of carbide inserts.

Grind your own HSS tools; despite the myths it is pretty straightforward. All you really need is a bench grinder.

Andrew

Jon Gibbs.