Hi Malcolm,

Whilst you can hold milling cutters in a 3/4 Jaw, personally I think it's a less than ideal solution.

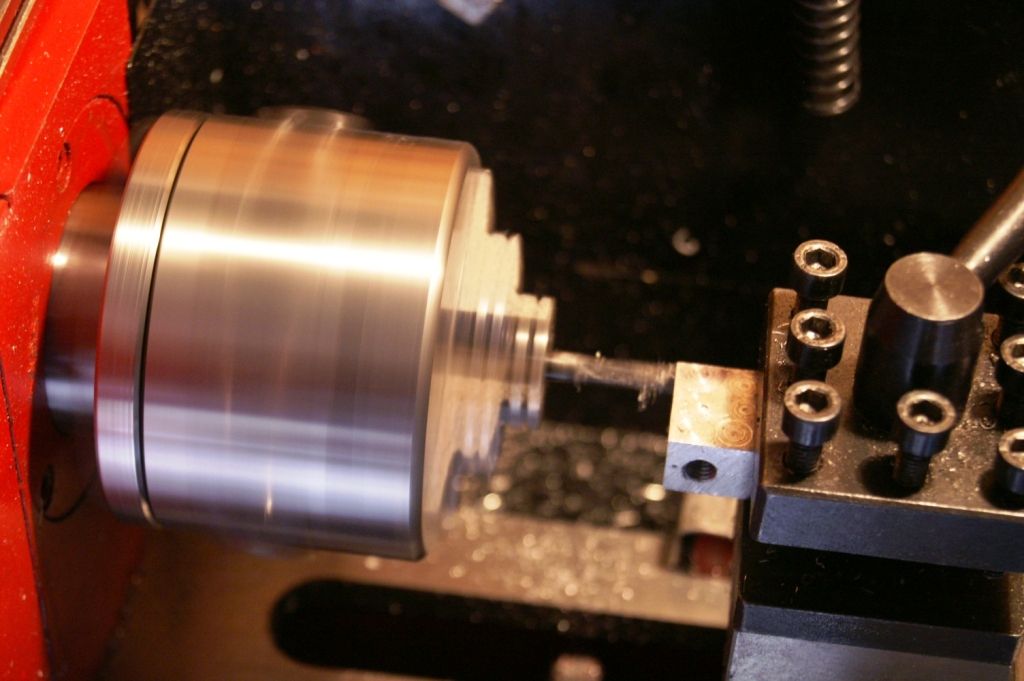

The most versatile solution would be to fit an ER32 chuck (via a suitable back plate) and this will not only hold milling cutters very securely but will also let you hold work in a more accurate and repeatable manner than a 3 Jaw. I have a ER32 chuck mounted on my 2.5" lathe which will hold up to 20mm material, which is useful for 3/4" material.

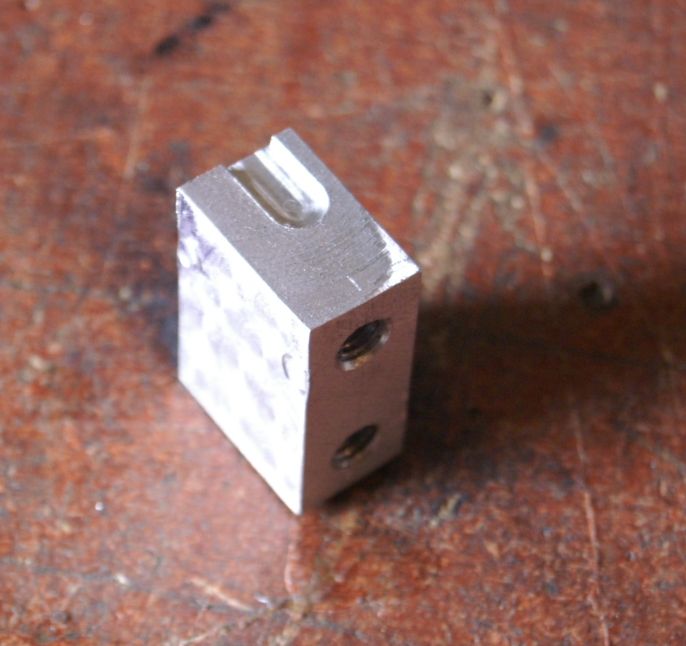

I recently purchased an MT1 taper collet (for use as part of a simple back-stop) and if you will only mill occasionally, particularly using a certain size of cutter, then this is a simple and inexpensive solution. My 6mm MT1 collet cost £5, which with a simple draw-in bar (e.g. a length of threaded rod & some nuts) will do the job very well.

As I've also suggested, with a short length of bar held in the collet – you will also have the basis for a chuck back stop for setting work to length in your 3/4 Jaw. With some suitable discs mounted on the end of that rod, it will also help you to mount thin work pieces in the front of your 3/4 Jaw – for facing off or similar operations.

One other thing to mention about MT taper collets, is that (apart from being cheap to buy) they also very much reduce the 'overhang' of the milling cutter (e.g. bring it much nearer to the front bearing), which can be a real advantage if your lathe is old & a bit worn (as mine all are) as this will help to reduce chatter and generally improve the cutting quality when milling in your lathe.

Regards,

IanT

Malcolm Marsden 1.