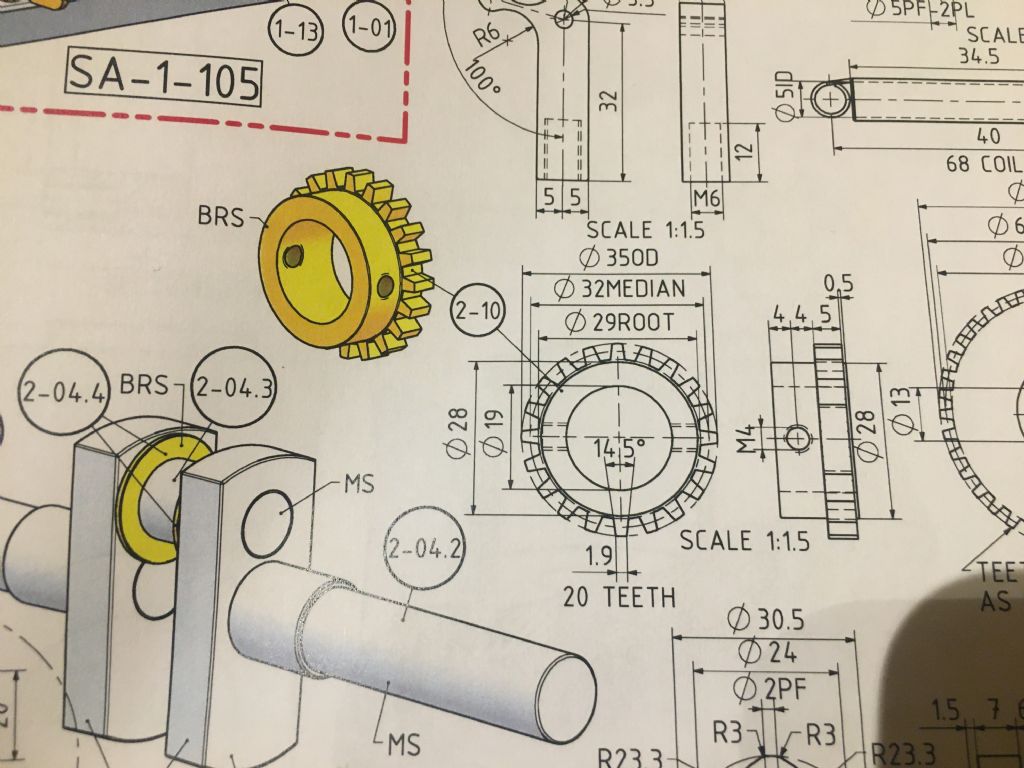

Posted by Andrew Johnston on 08/01/2021 12:00:43:

Whoever "designed" this engine clearly knows nothing about gears. The teeth are simply isoceles trapezoids and the included angle is incorrect for the assumed pressure angle. It's half what it should be. As drawn the addendum and dedendum are the same, which is incorrect. There's no clearance allowed.

There are two choices…

Andrew

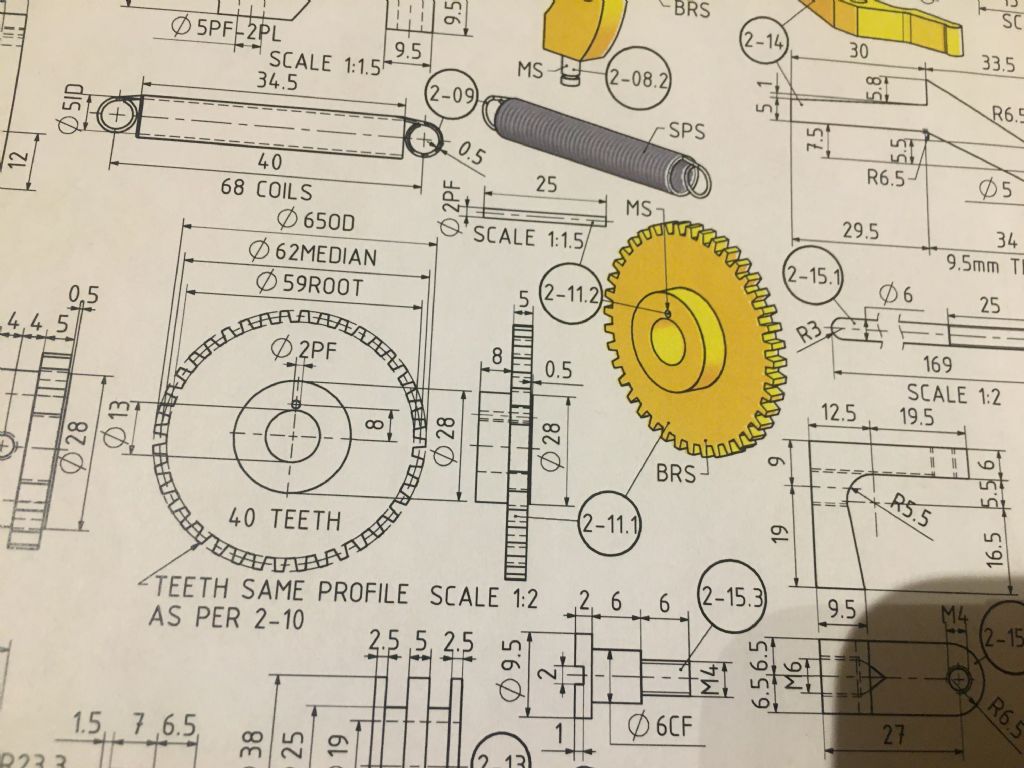

I agree with Andrew in that the teeth are simple trapezoids, not cycloidal or involute curves. But it may be deliberate rather than bad design. In the good old days millwrights and early engine makers didn't understand the maths behind gear shapes so it was common practice to approximate a shape and let the teeth grind themselves in. It's not a good system; at first the teeth are too tight and have to be filed to run at all, then they run inefficiently with much friction and wear out quickly. But it works and crude straight teeth are easy to make with a file. No need to worry about module, DP and gear cutting – the builder just needs to follow the plan, produce a bodged gear, and then fettle the teeth to mesh approximately.

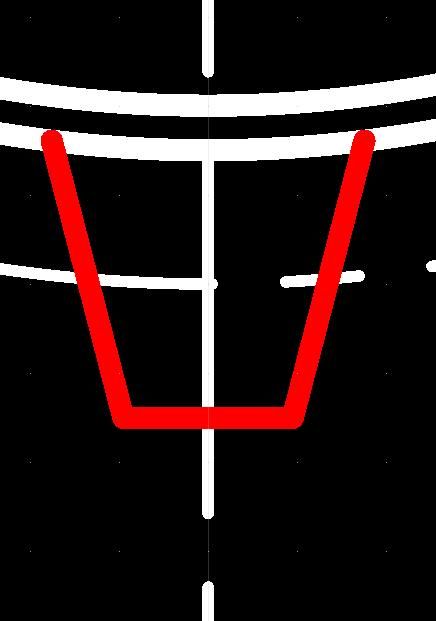

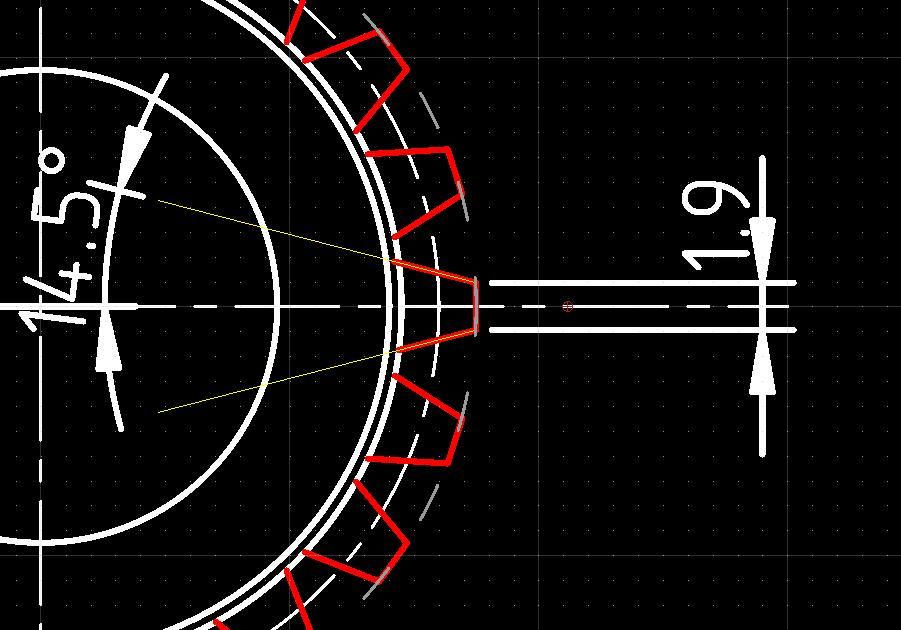

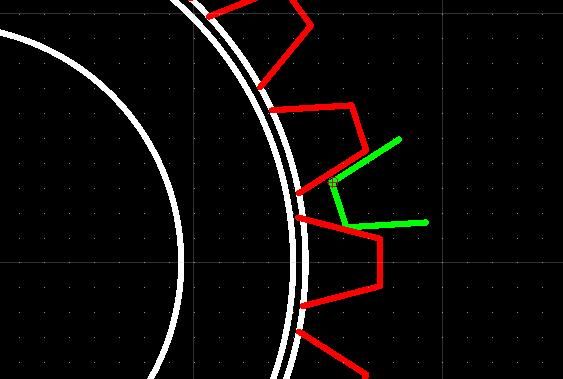

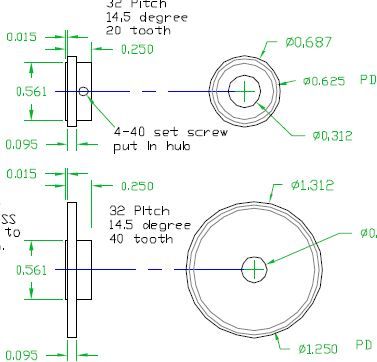

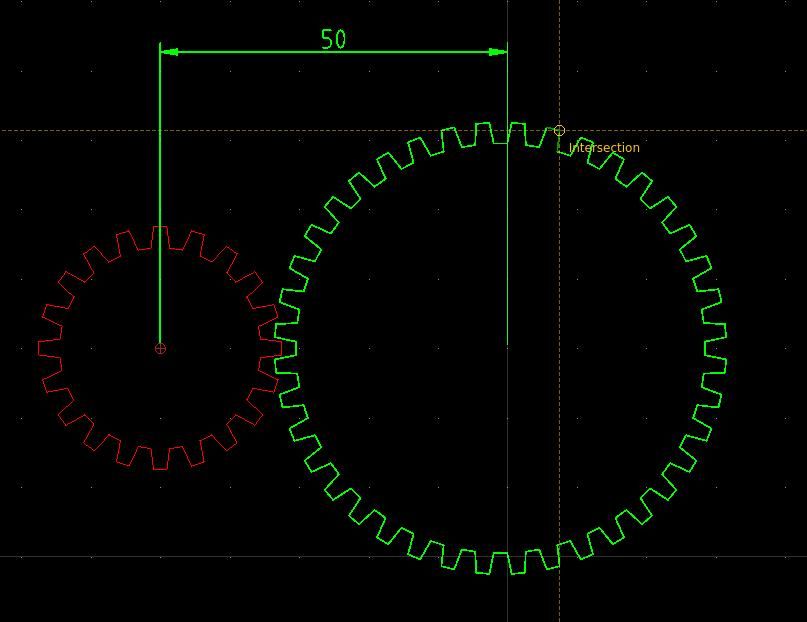

Zooming in on the drawing shows all the information is there; I've redrawn it for emphasis.

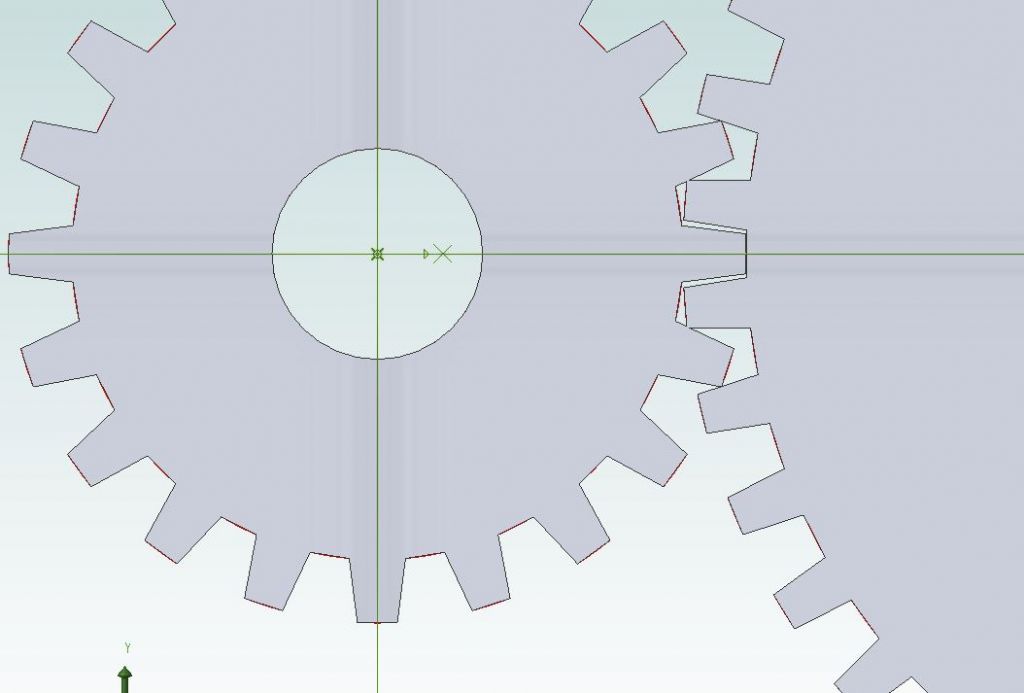

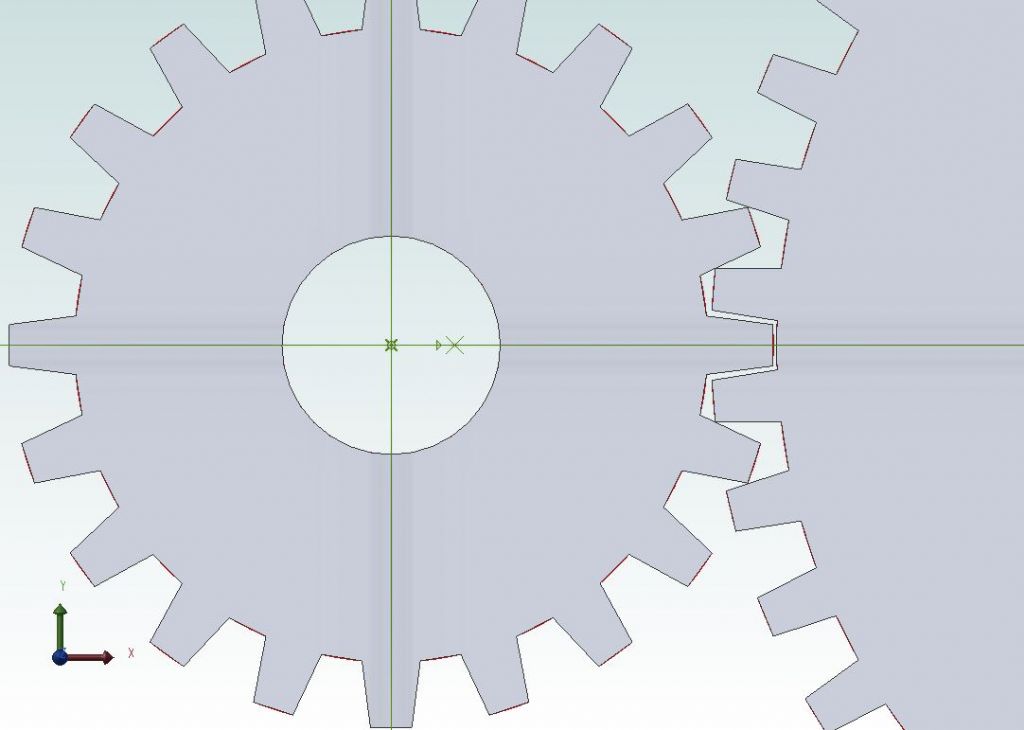

The shape:

With dimensions, 14.5° each side, 29° in total:

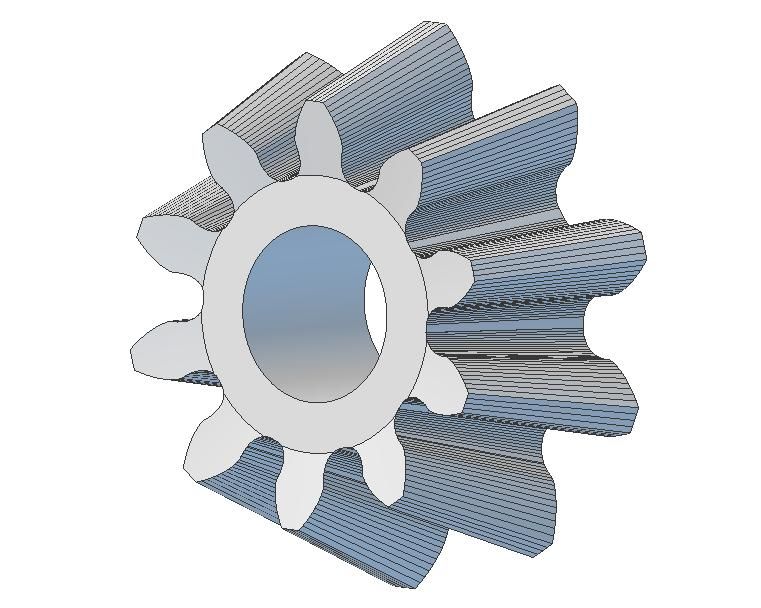

This last image shows how yuk the initial mesh is, and it's obvious the teeth will quickly wear to a more sensible shape at the top.

Nice job for a 3D printer. Easy to knock a couple of gears as per drawing and test them.

Dave

Edited By SillyOldDuffer on 08/01/2021 13:35:26

Anonymous.