Hello all,

I've bought m first lathe – an old Myford ML7. It's not in A1 condition – I couldn't afford one that is. Having got it home, complete with about 3 Lbs of swarf, I've made a start at cleaning and oiling.

question 1

I've got some iso32 as per the manual and (having cleaned/ unblocked/ repaired the drip-feed lubricators) i'm wondering what the drip rate should be set to – the manual says as slow as possible unless using high spindle speeds, but that's a bit vague for me so I was hoping someone might suggest a drip rate in, say, drips/min ?

question 2

The lathe came with a gun that appears to have grease in it and most, if not all, of the nipples that the manual recommends iso 68 for appear to have been greased. I've got some iso 68 which I'm using for the cleaned and reassembled crossslide/topslide, etc, but I am wondering if I need to clean out the grease or if it's likely to be OK just to put oil in through the nipples?

Q3

Do you think that a gun that has been used for grease will work with oil (not sure what the difference is betwen an oil gun and a grease gun, so I don't know if that which came with the lathe is designed for oil or not)?

thanks

I think the previous owner was i bit haphazard with his lubing – one of the dripfeed lubricators was assembled incorrectly and the other was filled with something that smelled like ep90 gear oil, and wouldn't drip at all.

David Jupp.

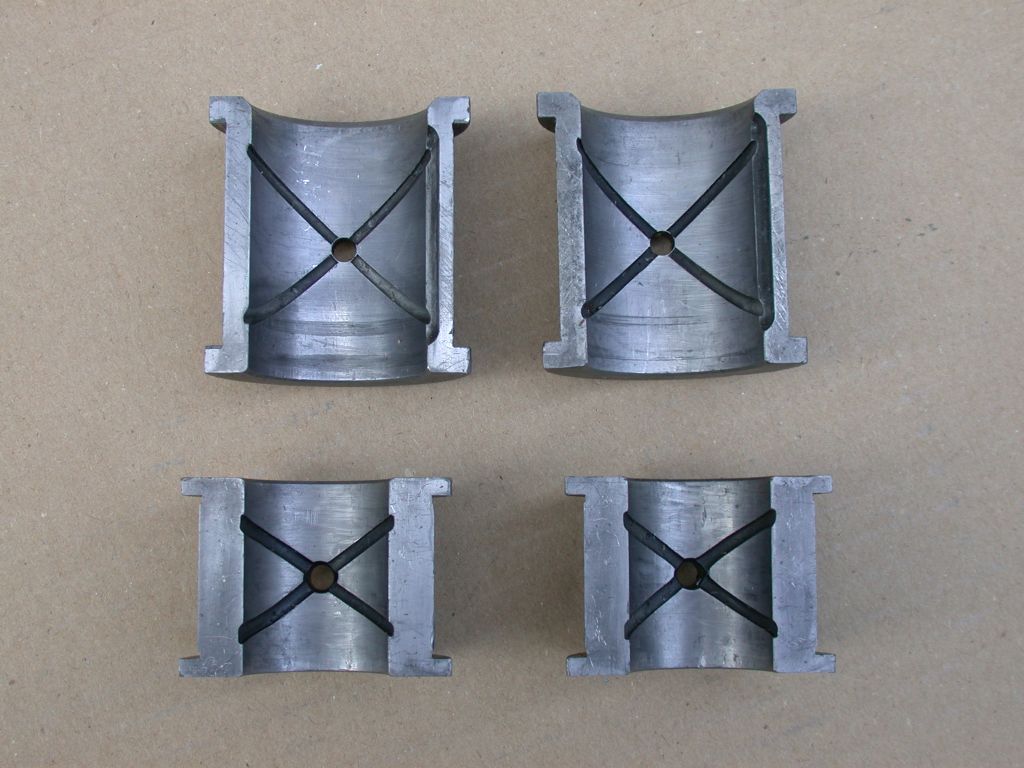

. I have run the lathe now the drip feeders are working and it's nice and quiet, except for the flapping of a loose bit of the motor drive belt. The cleaned cross slide and top slide feel quite nice except there's a lot of play between the screws and 'slides' – not between the screw and the 'nut' ,but where the screw turns in the end of the slide behind the handle – don't know if that can be shimmed up or something.

. I have run the lathe now the drip feeders are working and it's nice and quiet, except for the flapping of a loose bit of the motor drive belt. The cleaned cross slide and top slide feel quite nice except there's a lot of play between the screws and 'slides' – not between the screw and the 'nut' ,but where the screw turns in the end of the slide behind the handle – don't know if that can be shimmed up or something.