Dr_GMJN

Interested to see that you decided to have a small clearance between the top of the gib and the slide recess.

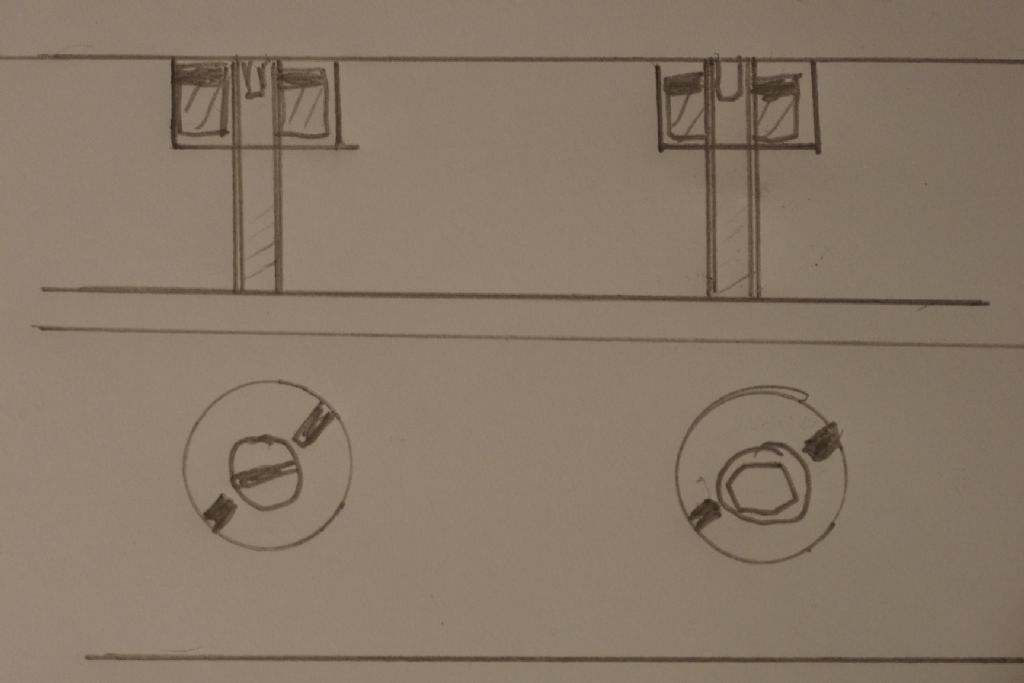

When I started doing such modifications I considered that the combination of a locating dowel and fitting the gib snugly against the top of the recess would pretty much remove any locating forces from the adjusting screws. Seemed that the system would be better behaved and much longer lasting when the adjusters only had to deal with setting clearance.

Thinking about things fitting it your way with a slight clearance lets the gib float sightly into its best alignment rather than being strictly constrained by fitting and machining accuracy. Potentially giving slightly tighter clearances and smoother working than my way, unless the fitting is essentially perfectly accurate.

Out in the real world such differences are probably moot. How good the workmanship and how well the job is done being probably more important than details of the method. Going for a small clearance is undoubtably makes it easier to do a good job so its probably the better method in practice.

Hmmn. Looks as if I could have saved myself a deal of fretting and extra careful work over the years if I'd thought it through!

A flat, angled pusher provides no location capability and does require the gib to be both dowelled and pushed up into the top of the recess. The pusher does remove the requirement for accurate registration of hemispherical end of the screw with the conical recess. Possibly better engineering but it needs sufficient casting depth to accommodate the pusher. Ideally the pusher should work in a plain bore so the threads ned to be drilled out and either re-tapped or an insert fitted. More work I think.

However the gib modifications are done the GHT thumb lever lock screw is a desirable addition.

Clive

Edited By Clive Foster on 02/11/2020 12:14:01

Dr_GMJN.