Some more progress on the motor bearings with photos.

I made the ‘expanding puller’. It took me a good deal longer than expected but not to worry. The core is a 6mm anchor bolt with the conical ‘expander’ from the same anchor bolt. I made a stepped bush from brass with an internal taper to match the cone and sawed it into four quarters. It worked a treat. The ‘indoor’ cap was still quite reluctant to shift but a bigger hammer did the business.

I also made a stepped punch to drive out the bearing bush. With a 12mm socket supporting the other side, I squeezed the whole thing in the vice and it came out easily once the initial ‘stiction’ had been overcome.

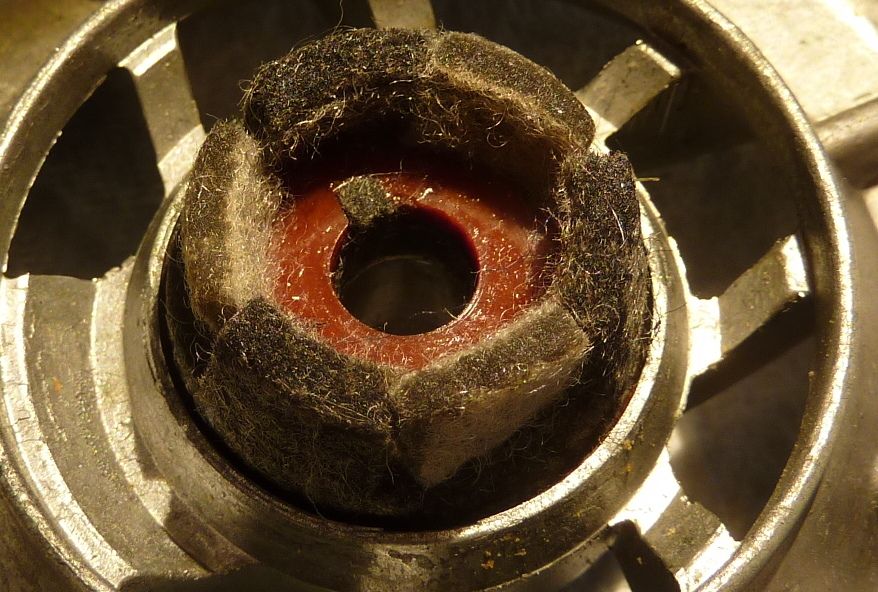

So the bush is clearly not oilite, nor is it anything bronze related. It is magnetic, so most likely either iron or steel. It has some sort of logo stamped on the outside. The bush is 376 thou (9.55mm) long and the OD is 422 to 423 thou (10.73mm).

The motor shafts mike at 316.8 thou where they run in the bearings – a fraction over 8mm… and too big to fit inside an 8mm ball race I think. There does not seem to be any measurable wear on the shafts which is somewhat surprising but perhaps indicates that the bushes are a good deal softer than the shaft.

I’m a bit disappointed that the bush does not seem to be a standard size… unless there is another standard out there somewhere that I have not found. Does anybody recognise these bushes?

So at the moment my least bad idea is to get some 8mm x 11mm oilite bushes and machine a small amount from both the internal and external diameters – ID first (with a boring bar) and then make a mandrel to allow me to machine the OD.

Regards, Andy

Phil Whitley.