Hi all,

Thanks so much for your advice everyone. Really helpful. Thank you also for your kind words regarding the weaving mill, I do hope that once we get set up you'll come and see them in action if you are ever in Suffolk.

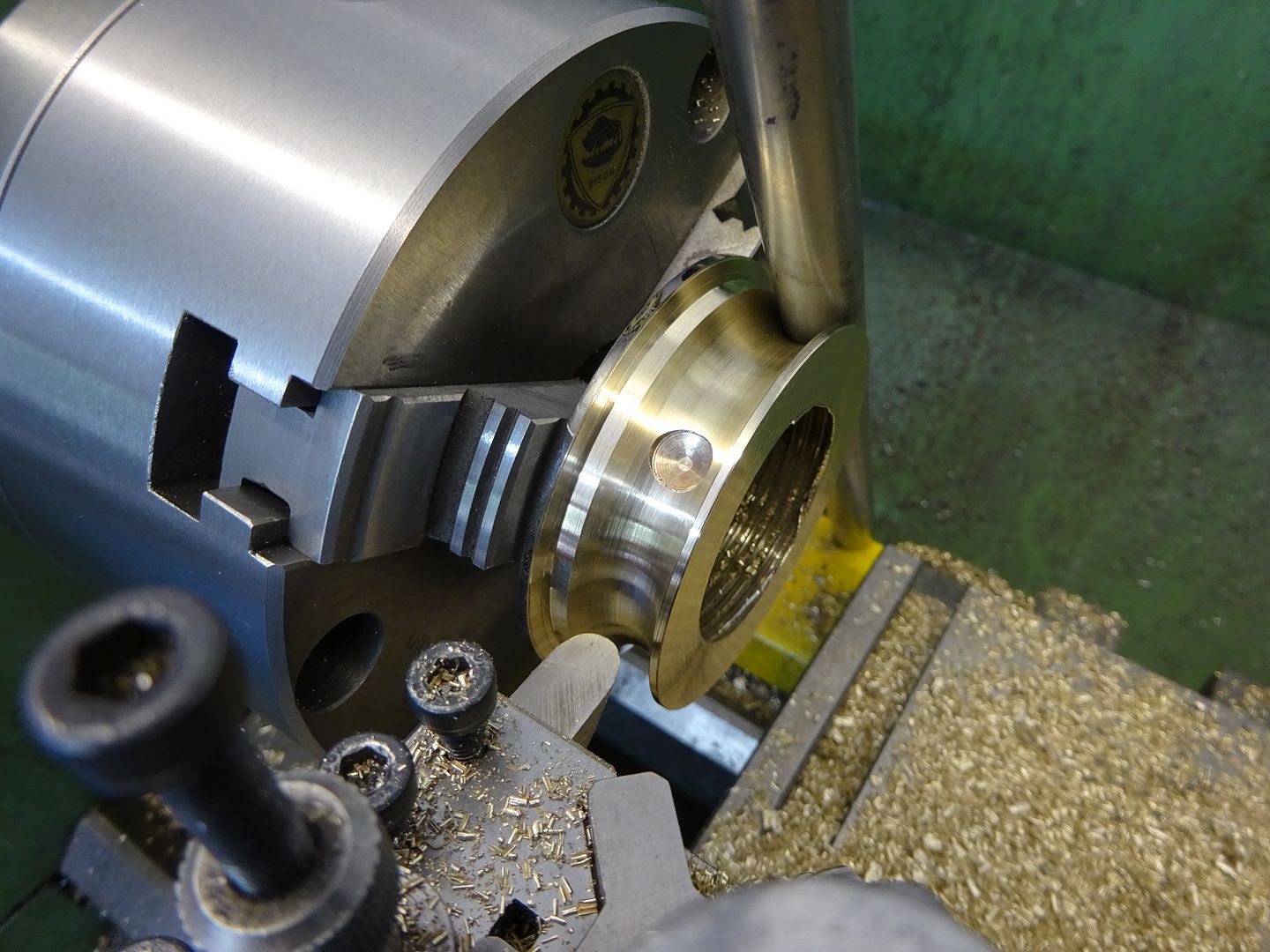

I have been thinking about the operations to make the pulley, watched a couple of videos etc. Most seem to use a mandrel for turning these pulley's between centres, with the piece glued on or fixed on with a press. However, I cannot make a hole larger than 6.8mm and that feels too thin.

So after going through a few options in my mind, this is the draft procedure I currently thinking of:

1) Mount the the 2 1/2" diameter x c4" long bar in the 3 jaw chuck, center drill and mount onto a half centre

2) Working at the tail stock end, size the 2" diameter of the pulley into the bar, with sufficient clearance for further work, and cut the angled faces (Parting tool to depth, a series of straight cuts coming out to decreasing depths and then angled cuts to smooth).

3) Reduce the diameter of the flange to 1" and face the flange and the side of the main section. Break edges

4) Either part off (or hacksaw off) the pulley with 1/4" waste to the left. Mount in to the three jaw chuck, with the flange facing out. .

5) Successively drill up to 6.8mm, finishing inside the waste piece (to protect the rear of the chuck)

6) Turn the piece around in the chuck, using the flange as a mount and bring up the half centre on the tail stock to support the work. Remove the 1/4" and face. Break Edges.

7) Increase the bore to 7.8mm to a depth of 0.625" (end of the thread) and then ream to 8mm.

8) Remove from the lathe to tap the end thread and drill/tap the grub screw hole.

Am I about right or way, way off?

James

Edited By James Jenkins 1 on 23/05/2016 15:17:00

Edited By James Jenkins 1 on 23/05/2016 15:18:11

James Jenkins 1.