I bought a WM14 mill at the recent Warco open day and took the opportunity to play with the display machine in the showroom that was fitted with the 'new' glass DRO system. The system seemed well made and so I ordered a 2 axis system to go with the new mill. Unfortunately the scales were out of stock for a while so I took the chance to get to know my new mill before summoning up the courage to drill holes in it to fit the DRO system. However once the scales arrived it was time to get on with it and get the job done.

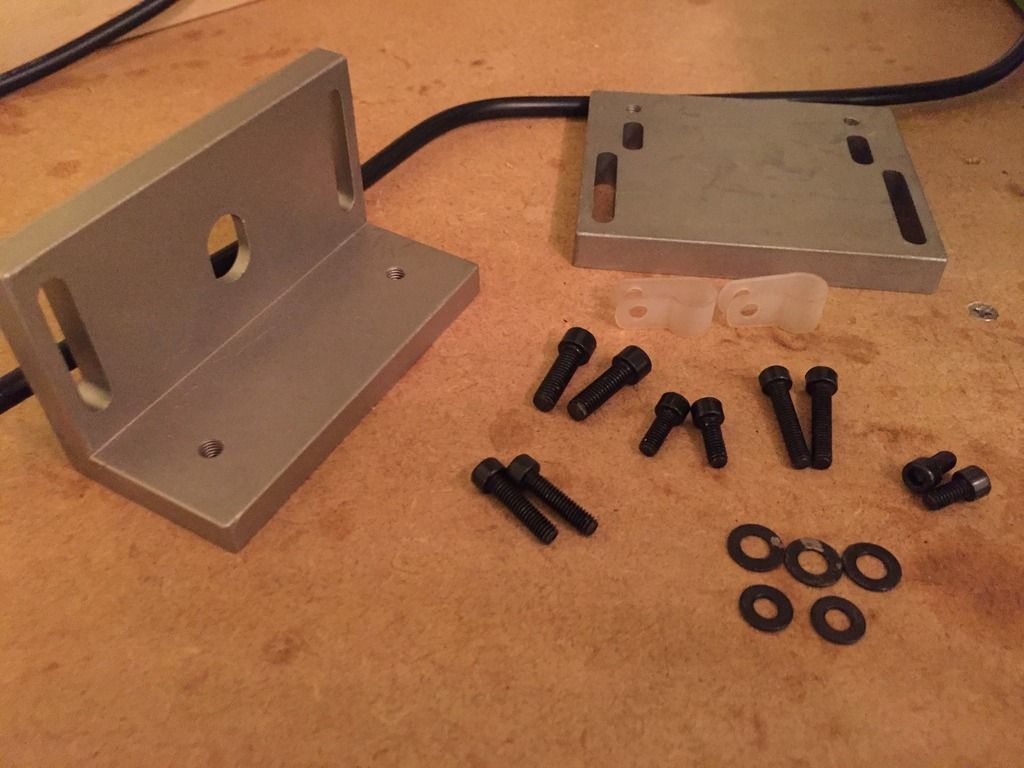

The X axis was quite straightforward and fitted well onto the back of the table, but the Y axis caused a bit of head scratching but I got there in the end. The installation of the Y axis system was helped greatly by the fitting kit that comes with each scale that includes a flat and angled bracket nicely cast in aluminium and a good selection of M4 and M5 socket head screws. Using the mill to machine these to size was quite simple once I had worked out what needed to fit where.

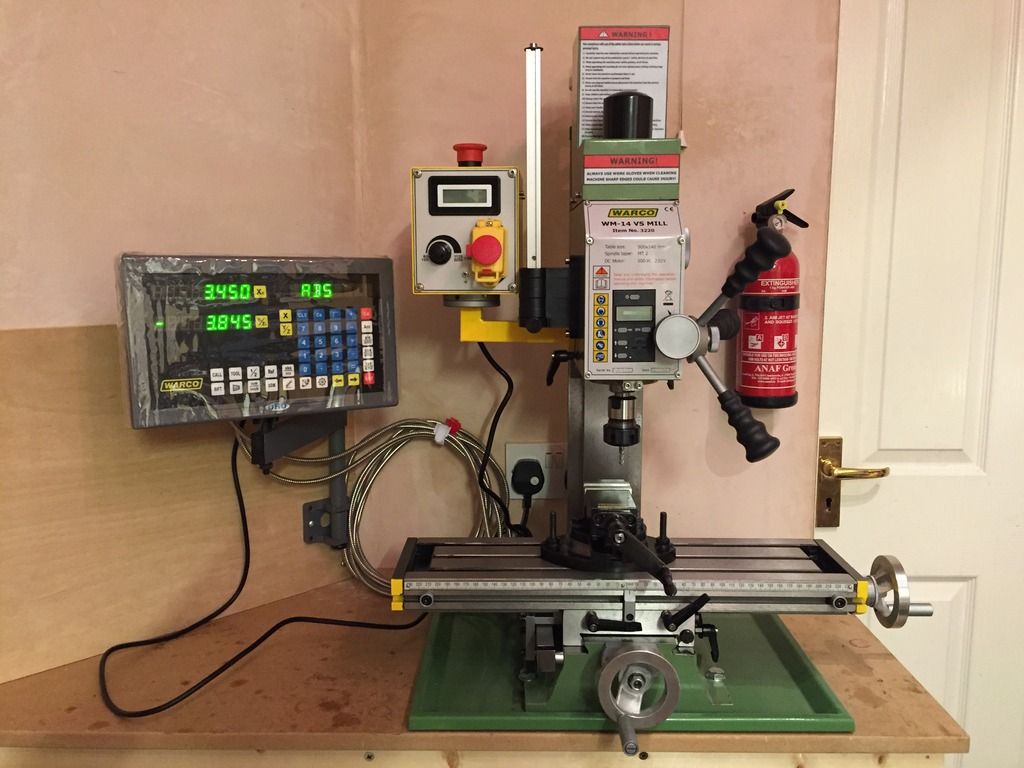

Here are some photos of the finished job.

Y axis scale showing cut down bracket and plate to transfer motion to the slider.

X axis scale at the back of the table. The only issue that still needs sorting is how to fix the rubber strip back in place in a way that doesn't channel swarf towards the scale.

Completed system working nicely. I wish the leads were more easily shortened but spitting a connector apart showed that they were very nicely soldered with the screened cables properly grounded to the connector body and so I decided to leave well alone.

The accessory kit that comes with each scale. This ended up being spare as it wasn't needed for the X scale.

Jonathan Mead.