In the build thread of this engine Adrian said

On 25 March 2025 at 07:22 Adrian R2 Said:

Looks more aerospace than Victorian. With what you now know about 3D metal printing, could this base have been economically produced in a batch with the slide, and possibly other parts?

So I have had a bit of a play.

If printed the bed would be better hollow as you would get on a casting so I used the “Shell” function in Alibre to remove the bottom face and leave all the walls 3mm thick, all holes were deleted. I then created a STEP file to upload and these are the costings, all include taxes and delivery

Aluminium SLM Printing

1off £75, 2 off £66ea, 5off £59ea and 10off £57ea

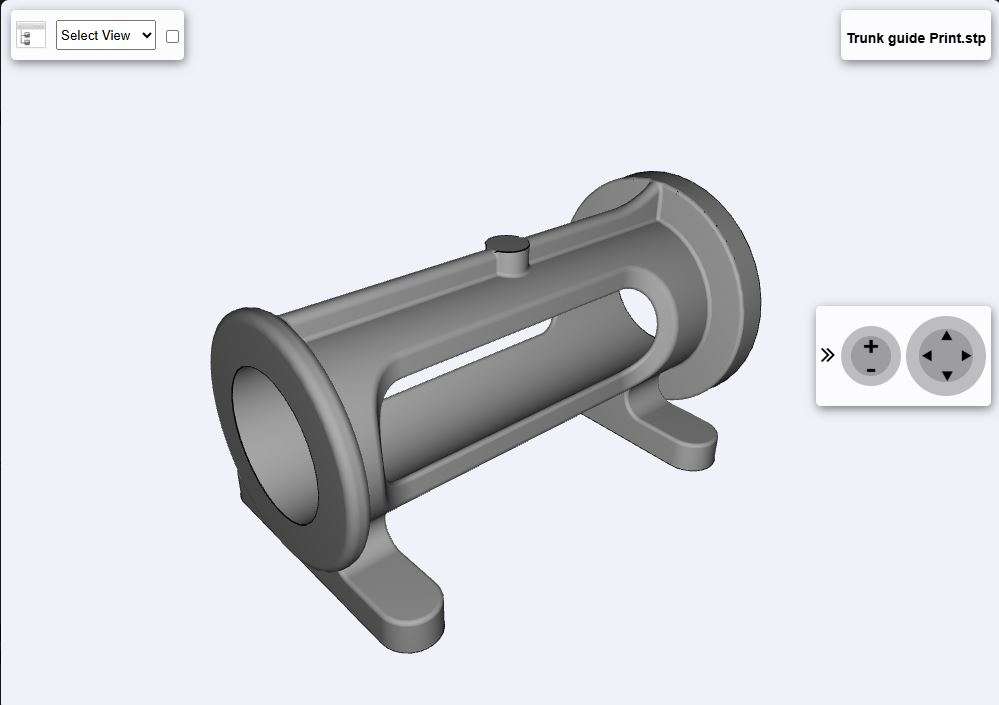

Aluminium DLMS Printed (same process as the trunk guide above)

1Off £135, 2off £107ea, 5off £92ea and 10 off £87ea

Aluminum CNC cut from 6062, Did not have the hollowed out underside for this as it would be an unnecessary cost

1off £128, 2off £95ea, 5off £87ea and 10off £84ea

By way of comparison, the Stuart No8 Sole Plate is about the same size and with VAT and delivery would set you back £90.50. So the SLM would be cheaper and likely to be as good a finish as your average ME casting. paying a bit more for DLMS or CNC is not massively more and if you grouped together with friends or sold on the extras all could be a similar price to a commercial casting.

Obtaining the weight from Alibre which came out at 420g for the hollowed out version I could probably get change out of £30 if I made a pattern and had it cast in iron and posted back to me.

As for grouping parts together, I tried that with a few linked by a simple sprue

In Aluminium DLMS £132 for one print or in Stainless DLMS £220 again for one print. Quantities would give similar cost savings to the single part. might be cheaper if the trunk guide were horizontal as it would half the number of passes the machine needs to make though I’m sure at the other end they would group several peoples jobs together to get the best productivity out of the machine.

So probably not something you would want to use all the time but if the part could not easily be made by other methods it would certainly be worth giving metal printing or even CNC services a go particularly if you could make use of the multiples. Things like castings that would have used complex cores which would not be easy to get at with a milling cuttre or fine fins like you get on an aero engine would be the type of job that this method would suit.

Adrian Johnstone.