Posted by SillyOldDuffer on 14/08/2018 11:51:06:

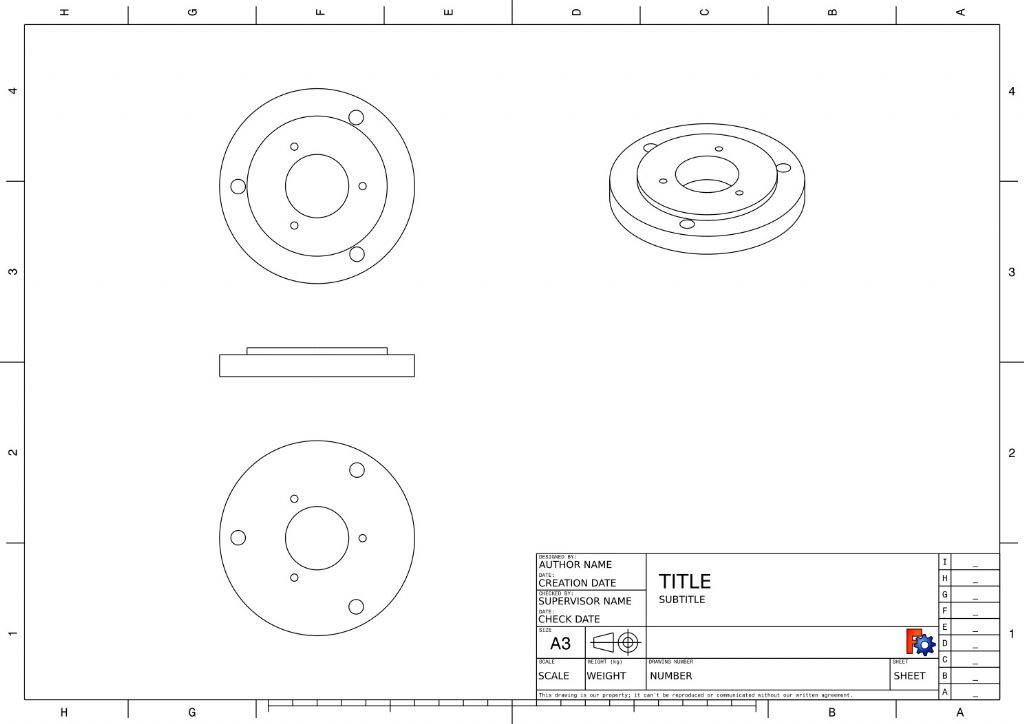

Just a quicky for hopper, there's no secret about what I'm making – it's a chuck back-plate being made from a casting for the same lathe.

Not sure how to get FreeCAD to add dimensions to a generated drawing, but the plate is 160mm diameter and 18m thick.

I don't think what it is makes much difference to the facing error, I could be facing anything. The way the casting was held in the chuck is more suspicious: although it felt firm, cutting pressure might have been rocking it.

I've decided to finish the backplate and will re-open the investigation when I face off the other side. Got a number of suggestions to try.

I'm hoping the issue is either:

- the measurement is mistaken and the lathe is fine, or

- that the cross-slide gibs are causing the cross-slide to move at a slight angle to the headstock and it's easy to fix.

No conclusions yet, just clues, theories and suggestions. I need to investigate more methodically.

Dave

Edited By SillyOldDuffer on 14/08/2018 11:52:22

OK. So the backplate should be bolted to the flange and finish turned across the surfaces the chuck mounts to while in situ so the chuck ends up running true to the spindle axis. (Is there a spigot or register of some sort on the spindle flange side of the backplate to ensure it always runs concentric to the spindle?)

If your facing cut is somewhat concave, it will not matter too much on the shown backplate. The chuck is located by the OD of the register step and the narrow flange of material outboard of that, which if slightly concave will not matter a whit. Chuck will locate on the outer area without rocking, which it would if the surface were convex.

Hard to see how the blank could be loose enough to magically wobble around in a conical shape without falling out of the chuck all together, or at least jamming up the tool etc.

If the cross slide is moving at an angle to the spindle axis, it might be a matter of cross slide gib adjustment, but it could also quite likely be a matter of the saddle sitting skewed on the bed, causing the cross slide dovetails to be skewed. Could be poor machining on the ways in the saddle, or wear, or just a bit of swarf in the wrong place.

Edited By Hopper on 14/08/2018 12:57:59

SillyOldDuffer.