Posted by JasonB on 13/08/2018 13:13:57:

Looks like Dave is using a raw sand cast backplate so can't bolt it straight on. To me the wrong face is being delt with first.

If I were him I would now turn the casting the other way round and clean up the back and machine off the boss which is not needed and bore the hole. It is not worth wasting time trying to get a flat cut on a rough casting held on a tapered (draft angle) boss which could be moving..

Once you have it bored and the mounting stud holes drilled and tapped fix it back onto the spindle and take your truing cut with a new insert and then see how flat the surface is. Only then start to worry.

Edited By JasonB on 13/08/2018 13:14:26

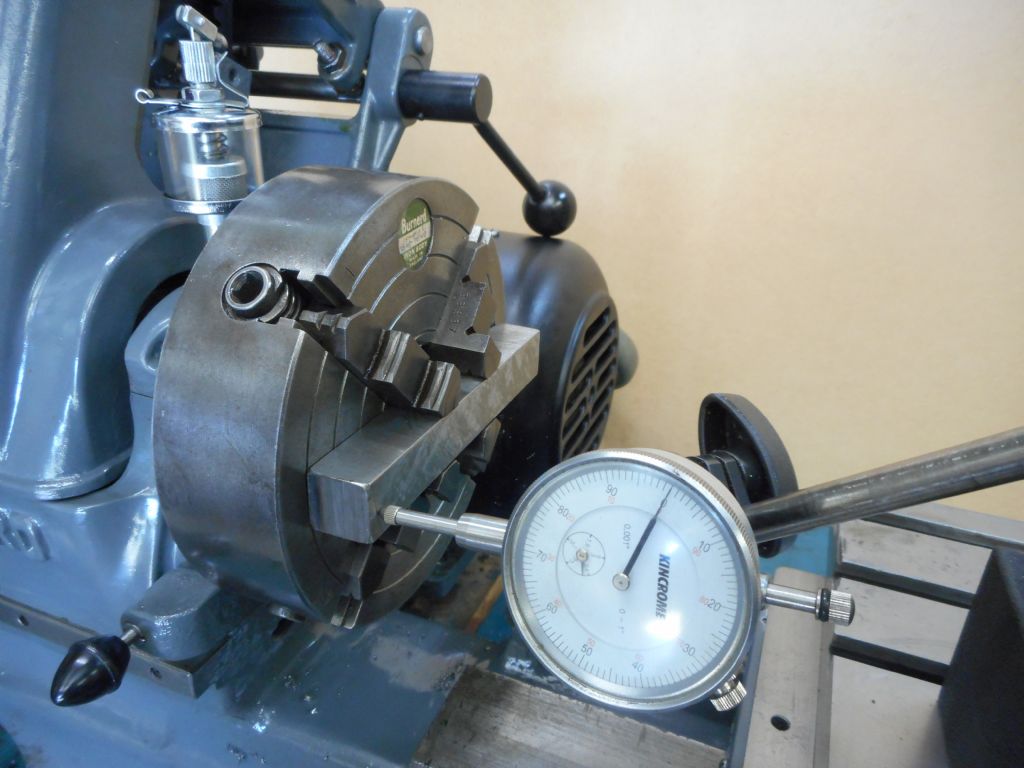

That's exactly what I'm doing, and I think you're right about turning the wrong face first! Trouble is I had to start somewhere and it seemed easiest to hold the boss in a 3-jaw, face off, bore the register and turn the outer edge round. How best to hold a raw casting isn't obvious to me. As far as I can tell the 3-jaw is holding the boss firmly, but it's certainly not best practice.

Part two is to transfer the backplate to my milling machine and drill & tap the backplate mounting studs, also drilling three clear holes to take the chuck studs.

Part three is to bolt the clean face of the backplate to the lathe's spindle, face off the dirty side,and finish by cutting a register for the chuck.

Even though the casting rocking in the chuck might explain the symptoms, I can't change course as Jason suggests because the register is already bored to size. When I move the backplate to my mill I'll be able to hold a test bar in my 4-jaw and test facing again as advised.

Dave

SillyOldDuffer.