Not so much keeping everything straight – more like starting straight. It is paramount that the first few threads cut are perfectly aligned with the tapping hole; as tapping proceeds after that, the tap will follow those initial threads. If they are off-line, the tap will progressively attempt to cut its way into the side of the tapping hole, increasing the load and eventually breaking (if the hole was deep enough!)

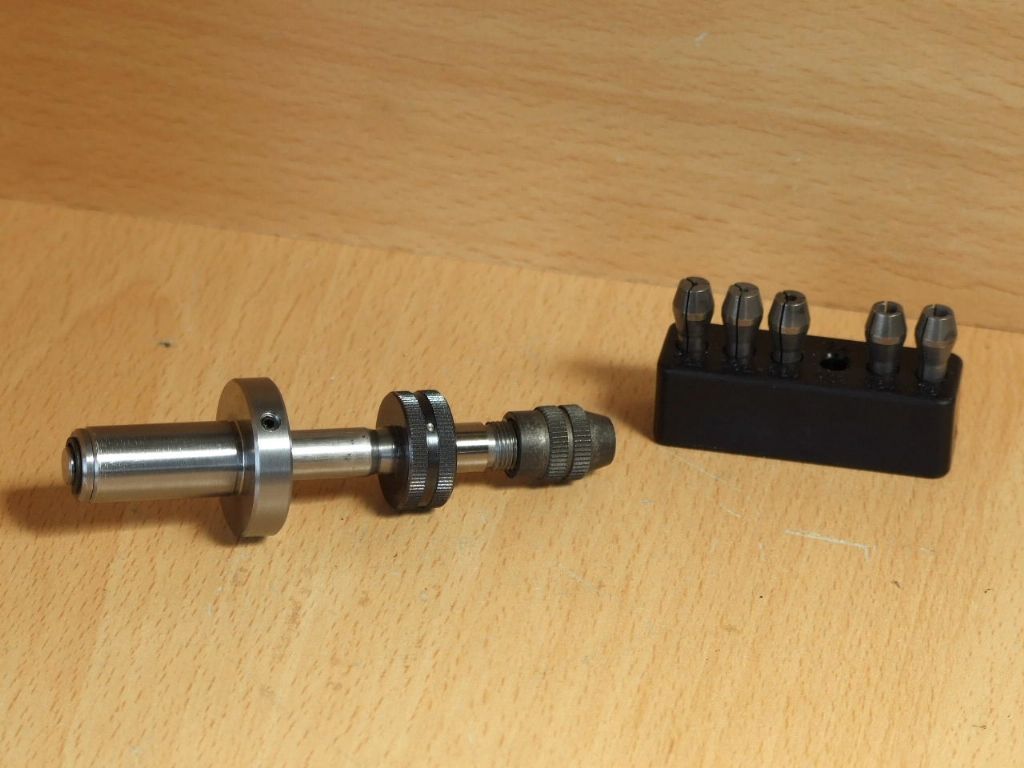

I always try to tap directly after drilling the tapping hole, without moving the machine position setting. The tap will fit the same chuck as for the tapping drill. Gentle downward pressure is maintained, to avoid stripping those first threads. A spring loaded tapping device is useful, if you are not confident, but that alignment is the most important bit – start right and it will end right.

Actual method depends on thread pitch and material, as well as machine. Like it must be a spring loaded quill unless a tapping tool is used. Hand tapping, as per Nimble, if off-machine. It has to be straight and if the hole is not vertical in the first place, tapping vertically will break the tap, given enough depth for the tap to dig in the side of the hole.

Small threads just need more care with alignment and careful progression, although any sized tap, not started aligned with the hole, will eventually break if tapping a very deep hole in tough material – that or stall you!

Downunder Dave.