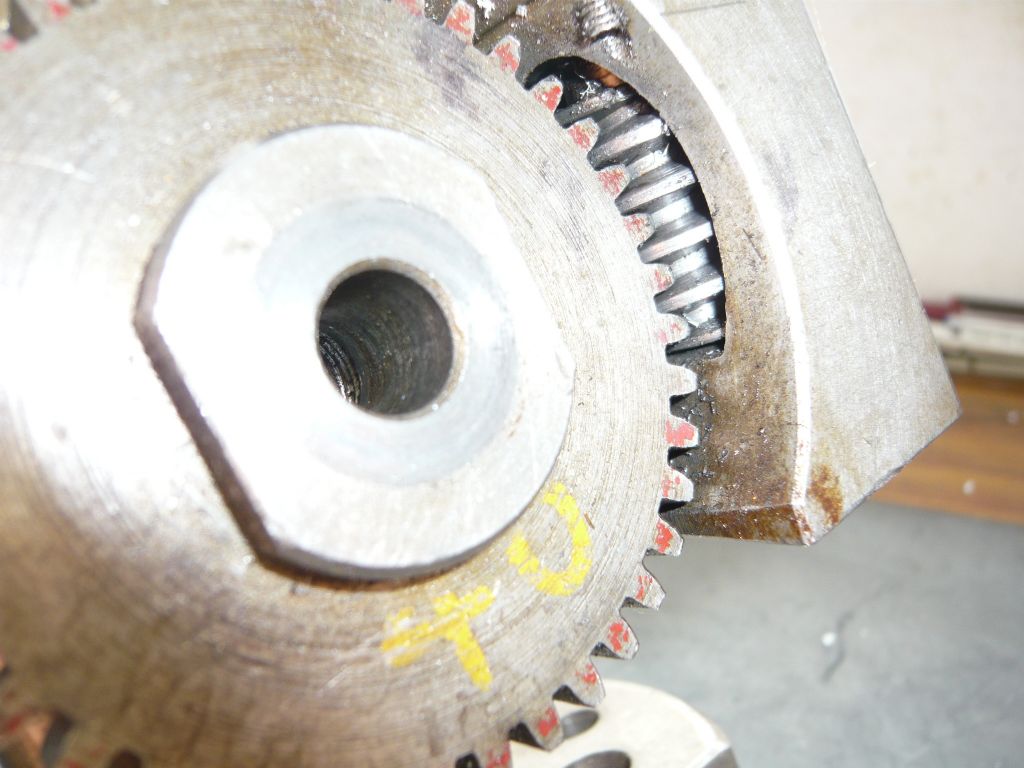

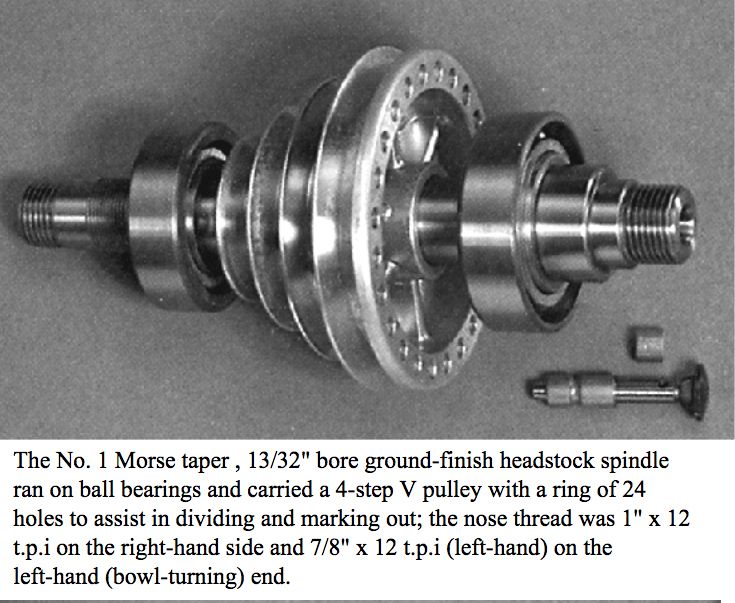

As Michael posted earlier, I'm (slowly) making a fabricated version of the GH Thomas dividing head. For worms and worm wheels, I have used a spare Myford 60T x 20DP change gear for the main worm gear. The worm was turned up on the lathe. By thinning the teeth on the worm slightly, the worm does not have to be offset by the angle of the helix. It runs straight in line. I think I picked this trick up from Martin Cleeve's book on screw cutting in the lathe. It works well so far.

For the secondary worm and wheel on the GHT design, I used the 60T Myford wheel with a plunger on the teeth to direct index the smaller 60T wormgear – so the GHT dividing head's first use is to make its own second gear!. Using a 32DP gear cutter from RDG, I kicked the vertical slide around by 4.2 degrees so the teeth are not a true helical gear but rather a straight cut gear cut at an angle, so to speak. With an Acme thread worm turned on the lathe it meshes straight on with no thinning of the thread needed in this case.

GHT's design is fiddlier to make than many other designs but has that classic look that matches my vintage lathe, and the nice but rarely likely to be used ability to divide accurately any number of divisions, including prime numbers, to a resolution of 1/1000th of a degree. Bit of a giggle really, but it does allow you to make your own extremely accurate indexing discs (or plates) using the dividing head itself and that secondary worm and wheel along with an indexing disc with one hole only.

So much fun, how could your resist? And so far the cost has been limited to a few offcuts from the local steel supplier and one 32DP gear cutter. The rest came out of the scrap box.

It's late right now but I will upload some pics of the latest progress to the What I Did Today thread tomorrow.

Here's a couple of older ones showing the Myford gear used as main worm wheel, and the worm that meshes straight with it by thinning down the thread.

Edited By Hopper on 15/11/2016 12:24:47

Edited By Hopper on 15/11/2016 12:27:00

Edited By Hopper on 15/11/2016 12:28:46

mark smith 20.