Hi folks

I picked up a cheap and butchered Denham lathe in January. Several Missing gear teeth and previous failed repair attempts, knackered bushes etc. Gears were fit to run in slowest gear of 6 speeds only.

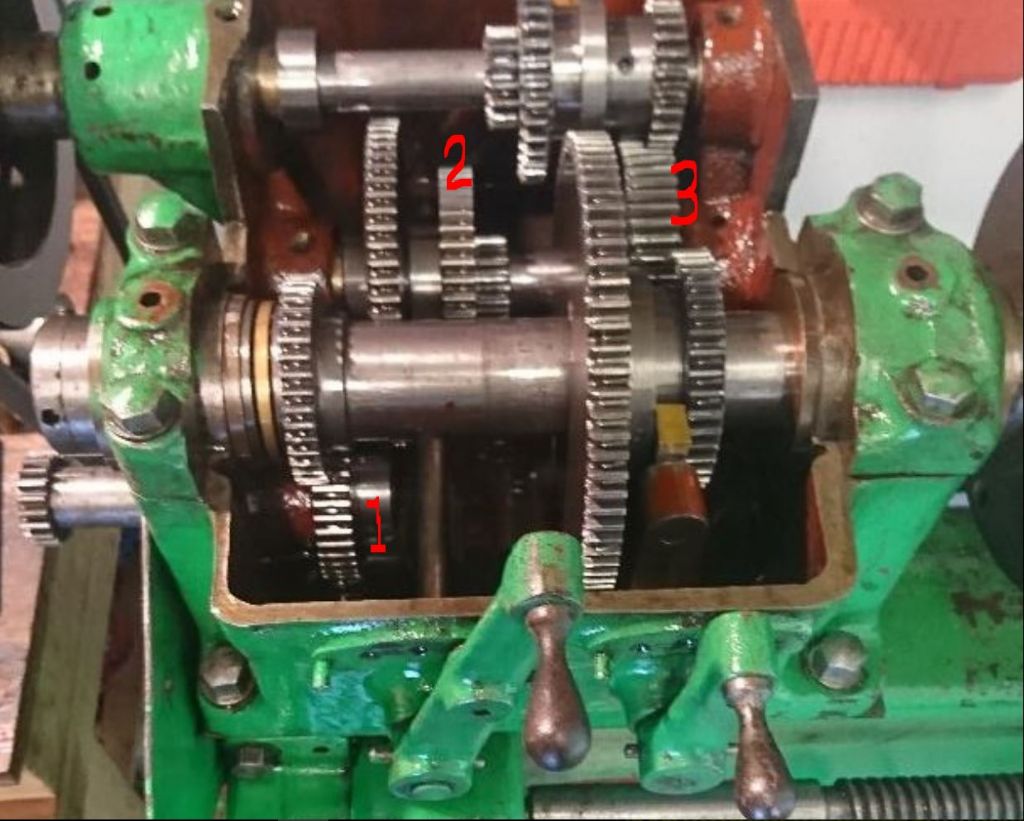

Mine is the type with two seperate gear levers, next to each other on the front of the gearbox, (plain headstock bushes for the main shaft, not ball races)

I'm Pleased to say I now have all 6 speeds working thanks to HPC gears, who list stock gears that are an almost exact fit. I list the HPC order codes and details below. I chose mild steel gears to run against the older cast iron gears and give them equal chance to bed in.

1/ SPUR GEAR 40T – 1/2"BORE 3/16" KEYWAY G16-40+S1201A S £62.92

This 16DP gear is driven by a gear at the thrust bearing end of the main headstock shaft mandrel. It is on the inside of the gearbox, on the end of the shaft that passes through the gear box wall to drive the back gears. The HPC code includes a smaller than normal bore of 1/2" and a keyway. I drilled and tapped its grub-screw as it has to be positioned on the boss close to the gear to allow for this stock gear being wider than the original. (14DP to match the back-gears by the way)

2/ SPUR GEAR 44T – 1"BORE 1/4"KEYWAY G14-44+S2501 S £47.59

This is one of the middle-sizes of 4 gears on the intermediate or "lay" shaft and is 14DP as per all gears in the box (with the exception of the 16DP back-gear driver above).

Because this HPC stock gear is wider than the Denham gear, I faced off around a 1/4" of the gear face, opposite side to the boss which I used to hold it in the chuck.

3/ SPUR GEAR 55T – 1 3/8"BORE 1/4"KEYAWAY G14-55+S3401 S 58.67

This is the other middle size gear of 4 gears on the intermediate shaft, this one sits on the right side, same end as the Chuck. I drilled and tapped the grub-screw hole but other than its larger I/D of 1.3/8" bore than the stock HPC gear, it dropped straight in. It is a wider gear than the one in the Denham but is fine.

PLAIN BUSHES

Plain bushes for the pulley shaft and intermediate shaft were picked up from ebay and simplybearings. I used sintered oilite types. Denmham used sensible ex-stock bush sizes.

RESULTS…

1/

I found there to be little or no backlash between the new 16DP (gear 1 above), which sits directly beneath the headstock mandrel shaft to drive the back gears. This caused an awful rumble. I deduced the main split-bush plain bearings of the mandrel shaft are wearing such that the shaft drops with wear over time, losing the backlash. Until I get to turn myself new split bushes for the headstock, I placed 0.007" shims beneath both the lower split bushes which recovered a sensible amount of backlash between the gears and stopped the rumble.

2/

At the highest chuck speed I do get quite a bit of gear whine but I think this will quieten as the new gear beds in with the old. I was concerned a new and old gear running together might cause the old gear to chew the new gear, but in practice, after an hour of running, there is barely a witness on the new gear teeth flanks and I can see it will take more usage under load than I can give the lathe in a year or so before it might bed in.

CONCLUSION

I hope this post might help out anyone else over time who needs to repair their gearbox. I suspect mine became damaged by someone on auto feed letting the saddle run in to the chuck. Something i've only ever done once..

that was 35 years ago at an industrial training centre. The chuck was a two-man lift and my mistake unknowingly slackened the chuck locking ring .. which went on to to undo later that morning. I saw the wobble as I turned the end of my soon-to-be tap wrench, braked the lathe… And the chuck flew off in to the rear splash gaurd. The lathe lifted half-inch at the front. Anyway.. A lesson well learnt. I used the same tap wrench to tap my new gears.

Brian Fosh

Brian Fosh 1.