Found something interesting about my Lidl Caliper powered from a clean battery yesterday – it can interfere with itself.

As the caliper only consumes 6 microamps, a 250kΩ load, I'd assumed a 9V battery and 10kΩ potentiometer would be stiff enough as a potential divider to power the caliper.

Not so! The caliper outputs about 140mV of noise at the battery terminals. This sufficient to cause a poorly regulated supply to dip below critical voltage, causing misreadings.

Using a 1kΩ potentiometer to divide 9V down to 1.55V is far more stable. With a 10kΩ pot the caliper fails at 1.48V, with a 1kΩ pot it worked down to 1.40V

With the caliper operating correctly at normal full battery (1.55V), I injected noise into the supply. 9mV of external noise is enough to randomly toggle the minus sign. With 40mV of injected noise, the digits start flipping occasionally. At 90mV they flip continually.

In short, the caliper is:

- intolerant of low battery volts – the caliper stops working when its SR44 cell drops 0.15V from new.

- sensitive to electrical noise on the supply, including it's own!

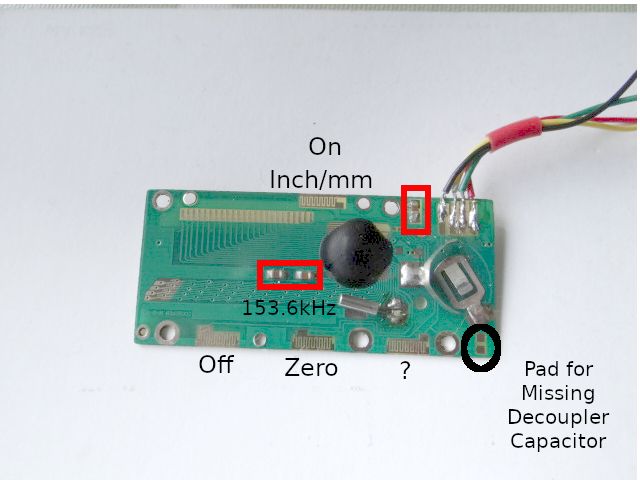

Going to take it apart later. I expect to find no decoupling because the caliper normally relies on the battery to smooth out internal noise and eliminate external noise.

Making calipers work with an external supply is probably quite simple – relatively low impedance volts (like my 1kΩ potential divider), plus a decoupling capacitor at the caliper terminals to get rid of any noise. A shielded or twisted cable decoupled at the power supply as well would be prudent.

For a small fee I might measure how many volts are needed to kill the caliper. It took an accidental 1.9V without complaint. Fussier about too few volts than too many.

Dave

Michael Gilligan.

Michael Gilligan.