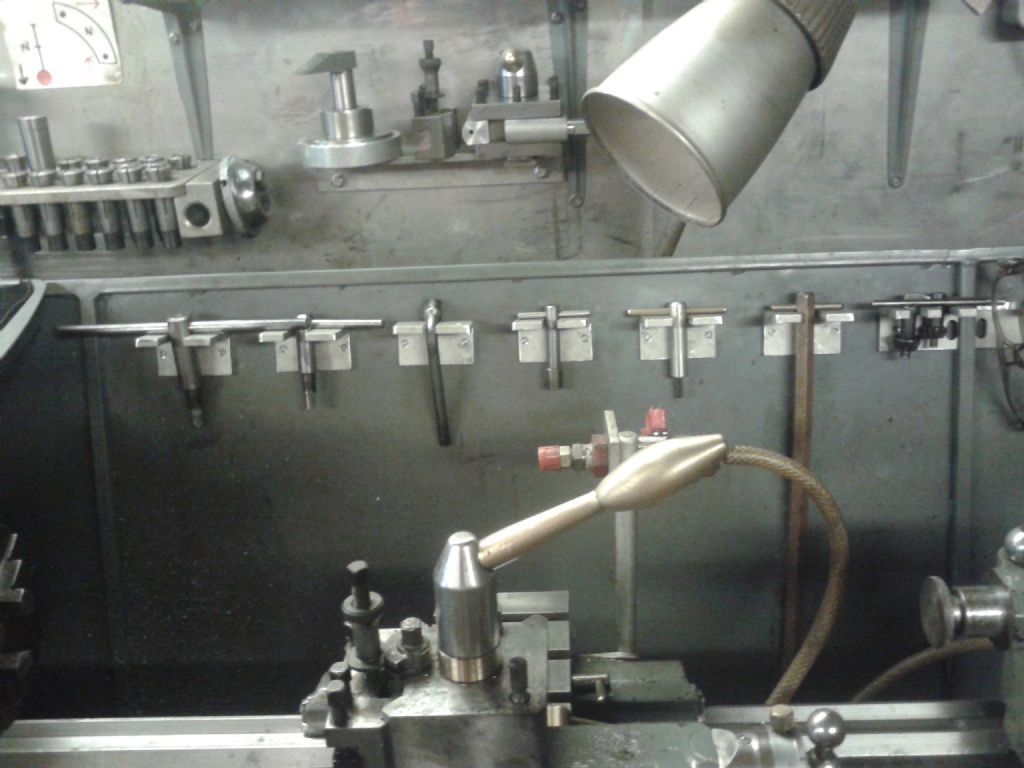

I'm afraid that I always replace a tool as soon as I have finished with it.

Along the front of my S7B swarf-tray are a number of very strong 'earth' magnets which hold all my chuck keys.

The swarf-tray is covered in absorbent pads which contain all the oils and the swarf, and, as I have a free and

guaranteed continuous supply I simply remove them all, put them in the bin and put fresh ones on the tray.

So, there are NEVER any tools on the swarf tray as everything is close to hand.

Everything I know re home workshop I learned from 'Curly'.

OK – so I have to walk two steps to replace drills. Disabled I may be but I can manage that.

Taps and dies (not B.A. which are in a block), D-bits and slotting cutters are in small drawers which are hung

on the wall.

The shed measures 12' x 8', well, not quite as there is 3" of roof insulation and another shed built inside so it is never really cold in there.

A dehumidifier runs from 04.00hrs to 11.00hrs so there is no condensation.

The last thing I do when I leave early evening (I am a carer so time is limited) is to sweep the floor, check all digital read-outs (verniers etc.,) are off then kill the main dis-board. There is one twin 13amp socket which by-passes the dis-board and this supplies the dehumidifier and a small oil-filled radiator.

The machinery consists of a Myford S7B with rack-feed on the tailstock and powered by a Newton-Tesla converter

which is one of my 'best-buys';

A Warco WS16 mill with all it's accoutrements on shelves close to hand; the table is covered with 3mm plastic so I just brush the swarf into a dust-pan – the vice has not been moved since squared and bolted down.

An Italian band-saw and two bench grinders – one of which now sports a diamond disc and a 50 yr. old grinding jig which I have altered to give fine feed and does an excellent job.

Thanks to MEW for the instructions for several small bits and pieces and I do NOT have a SWMBO.

Sorry for the long epistle – just thought there might be some one else of the old era (I'm 84) who remembers the old days when people usually had only a lathe and built superb engines.

I will now go and play the organ, which, according to my G.P is excellent physical exercise!

Regards to all and just enjoy your workshop.

Richard.

Howard Lewis.