Posted by Hopper on 15/11/2018 01:03:18:

This thread here **LINK**

includes pics posted by Mr Stevenson himself of a remarkably similar looking lathe, showing the moveable banjo plate that pivots around the leads screw boss via pinch bolt visible in his pic. There also appear to be slots in the banjo to move the gear stud to accommodate the larger gear.

Does yours not have this piece in place?

There are also other pics in later posts in the same thread showing another type of banjo mounted more centrally between leadscrew and headstock spindle.

If you don't have something like this already, you will have to make something up to approximate it. Seems odd that they would supply the 127/120 gear but no facility to move the stud to fit it?

I just looked at your original picture again, turning it right way up for clarity, and it sure looks like there is something there where the quadrant should be. That grey unpainted piece of cast metal behind the leadscrew gear? The one the idler gear stud appears to mount to? What is that?

Edited By Hopper on 15/11/2018 01:12:55

Thanks for finding that thread Hopper – JohnS did say he had a very similar lathe. I now see what the problem is, though I'm not sure how to solve it yet!

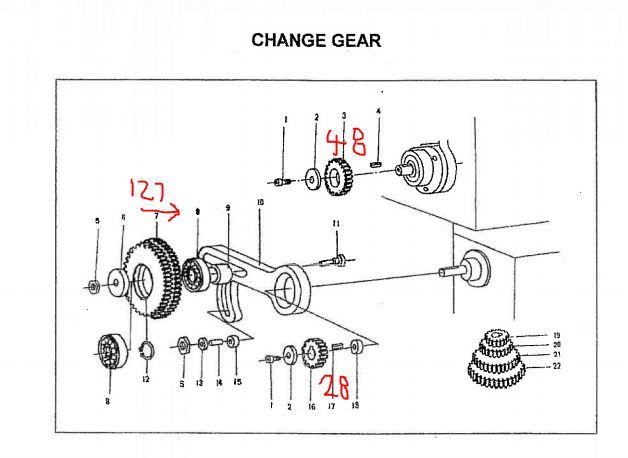

This is John's pic of the gear train on his machine taken from his thread:

There is a spacer behind the wheel driving the 127/120 compound which allows it to reach over the 120 and engage with the 127.

My machine:

The drive shaft doesn't extend far enough to allow the drive wheel to engage with with the 127T in the way shown in John's pic.

I now understand how it's meant to work, I just have to figure out how to fix it – any suggestions welcome!

Robin.

Brian Wood.