Ian P

When I purchased the machine from new all it ever had was the no volt switch on top of the motor.

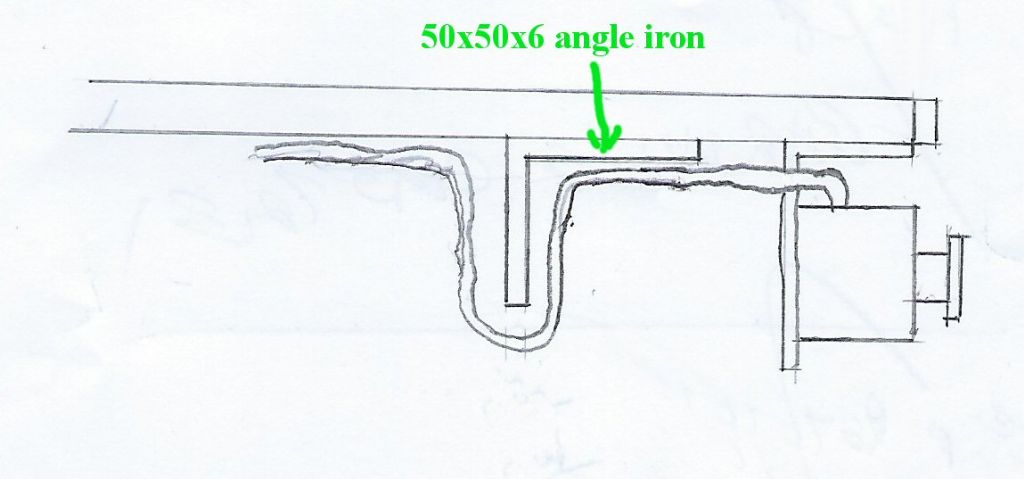

The cable came out from the side of the switch box and had a three pin plug on the end of it. Because I did not want to drape the cable over the top of the machines for obvious reasons, it was passed down through the same hole the chip extraction hose goes through and from there was plugged into a convenient socket outlet on the wall.

To turn the machine on or off was a case of having to reach over to do so, as matter of fact sometimes when I wanted to switch the machine off, I’d use a piece of wood save stretching over.

My plan now was to fit emergency stops and bring all the wiring from them into the switch box on top of the motor, doing away with the original switch altogether and putting a steel blanking plate on top of box.

The cabling would then come out of the side of the switch box including the power supply for the motor down through the hole in the table and the DOL would be fastened to a board and either hung on the side of the machine I’m working on or on the wall and from there a short cable with a three pin plug would be pushed into a convenient power point.

I’d love to be able to fix the DOL starter in one permanent position but because the whole machine has to be moved around due to space limitations, I can’t do that. ie if the machine was pushed against the wall the DOL was permanently fixed to I’d never be able to reach it.

Ian I dare say a lot of the guys on this forum have metal turning lathes or mills, a woodwork machine such as mine needs a lot of space, think about it, if I have a piece of wood to be planed and say its 8 foot long the machine will need at least 18 feet, 8 foot going in and 8 foot coming out plus enough space to feed it in and get it out of the machine so that’s why sometimes the machine is shoved up against a wall.

Believe me I am trying to persuade my wife we need to move, I am working on it  .

.

As you can see I’ve never had E/stop buttons on the machine, I was thinking I could use them to turn the machine off without the need to turn off at the DOL, having said that I don’t even know if this would have any adverse effect on the DOL or indeed if an E/stop has been operated I’d have to take the cover off the DOL and reset anything I’m hoping not.

Thank you for your comments they are much appreciated .

Clive

Former Member.