Many thanks to everyone for the replies.

Jason, I should have mentioned (my post was already a bit long, as this one is!) that the steel back plate is only mechanically fixed to the brass channel (with five CSK M3 screws into blind holes), and of course regardless of how small my mill is I can do this mechanical fixing after brazing. So your suggestion to file out the rounded corners after milling is even more practicable – provided I have the skill to file perfectly flat and square. There's the rub – almost literally.

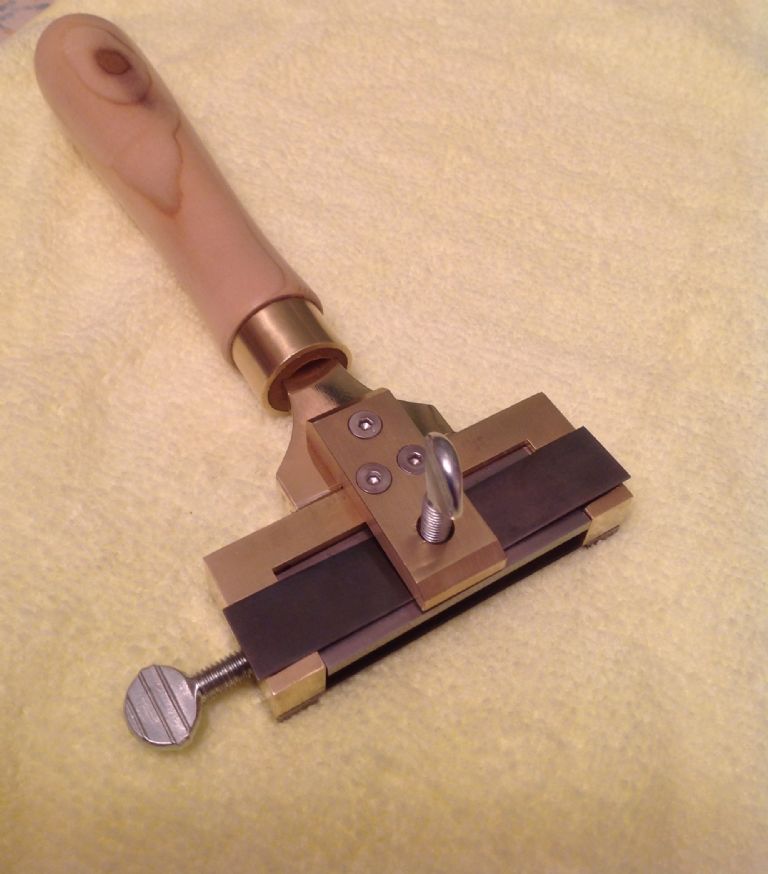

Absolute flatness of the long internal edge is critical everywhere except, in practice, in the corner where the side screw comes in; here there is always at least some projection of this screw into the cavity, meaning that no type or spacer sits directly up against the vertical side at that end. However, at the other end, a finishing spacer is always placed after the last letter of the word right up to the stop to fill out the chamber, so things here need to be perfectly flat and square, no ifs or buts.

Hence, using Keith's suggested "455" looks as if it would reduce the flow temperature slightly, so it might be worth a go.

Martin, your question is a crucial one. The temperature at which the type is worked on the book is probably no more than around 150-180 degrees C at any time. However, the tool has to be brought down to this temperature after it is taken off the stove by damping it on a moist pad, and in practice, in trade binderies particularly, so-called "finishing tools" such as typeholders are left on the gas or electric stove for long periods, even all day, so that they are ready for use almost instantly. This means that they can reach quite high temperatures. As a consequence, using a soft soldering process is fraught with risk, and using epoxies probably even more so.

This is one of the reasons why bookbinding type is brass not a lead/tin/antimony mix, which is what I believe most letterpress (i.e. printer's) type is. I do use letterpress type occasionally in a typeholder (it is much cheaper than brass type) but you do have to be careful not to leave it on the stove too long, or it will distort or worse. What tends to happen first of all is that the pieces that get too hot start to expand upwards (they can't expand sideways because they're trapped in), and they then become useless because they are permanently of a different height from the rest of the type. This brings us back to the reason why absolute flatness and squareness are necessary for the chamber of a typeholder.

I think this project has shown me the limitations of having such a small mill. Once I've got an idea where I can put it, a proper-sized machine beckons.

ETA: Martin, yes, these sorts of typeholders are always used by hand and usually across the spine of a book. If they are used on a flat board (i.e. on the cover of a book) you do have to exert considerable pressure to get a good impression – sometimes, for bigger font sizes, with all the strength you've got.

Edited By Bill Phinn on 26/02/2019 18:51:05

Bill Phinn.