If you sort your headstock problems out the usual other ones are pretty simple.

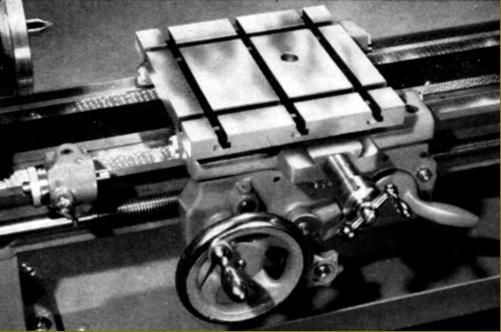

The cross and compound slide are best set so that there is a bit of resistance to movement. Easiest way to do that is to remove the leadscrews and push by hand. Slideway oil helps a lot but often there is sufficient wear to prevent the same level of stiffness over the full travel. If this is done via the handle it's too easy to over tighten. If it's a case of it being a rather stiffer when the slide is pulled out as far as it can go when the lead screws is in that's not too bad really and will probably work out in practice. I reckon that slides wear more quickly like this because people often set them so loose.

The beds wear but unlike some others this doesn't usually spoil the finish the lathe can obtain but can introduce a taper when turning. They have a lot going for them in this area as the ways are so long on the saddle but it does happen with a lot of use. I had a Viceroy that turned around a 0.005" taper over 4 or 5in due to that on say 1" dia bar. Smaller bar would be worse. If checking that sort of thing by turning the bar may well bend and give a taper.

If the bearings don't look nice and fresh and are scored etc it doesn't cost much to replace them but it's best to turn up the discs etc needed to press them in first. There are cut outs in the head to allow the outers to be drifted out – evenly of course. The front bearing cone replacement needs a bearing press in my view. To much chance of wrecking the spindle without it. Mine is so tight I reckon they use a bearing heater to get it on. The numbers for the bearings needed are on the group but can be hard to find so I collected the info here

**LINK**

I think boxford can still supply them too. I get the impression they supply standard bearings.

The rear bearing cover may need machining on some lathes when the cheaper bearing is used. This doesn't seem to cause people any problems but mine fitted without any machining. I don't see why the machining couldn't be done after the headstock has been fitted and set up etc. It is just a cover.

Give you a few things to play with Ian while waiting for bits.

Give you a few things to play with Ian while waiting for bits.

John

–

Ian Rees 1.

Give you a few things to play with Ian while waiting for bits.

Give you a few things to play with Ian while waiting for bits.