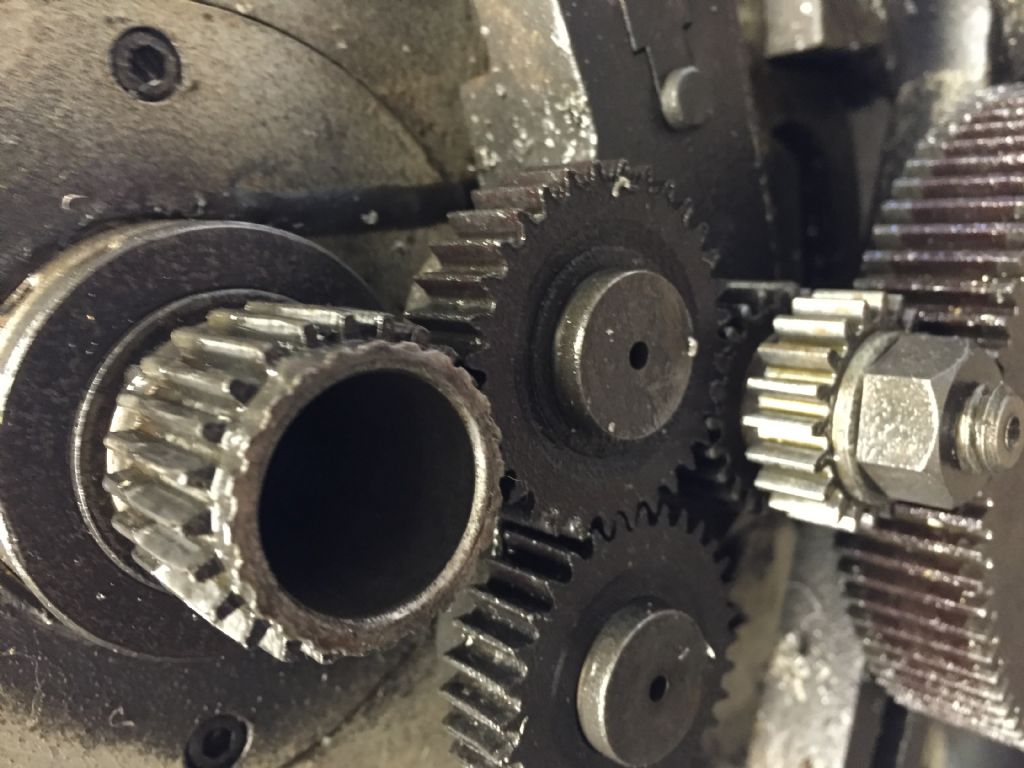

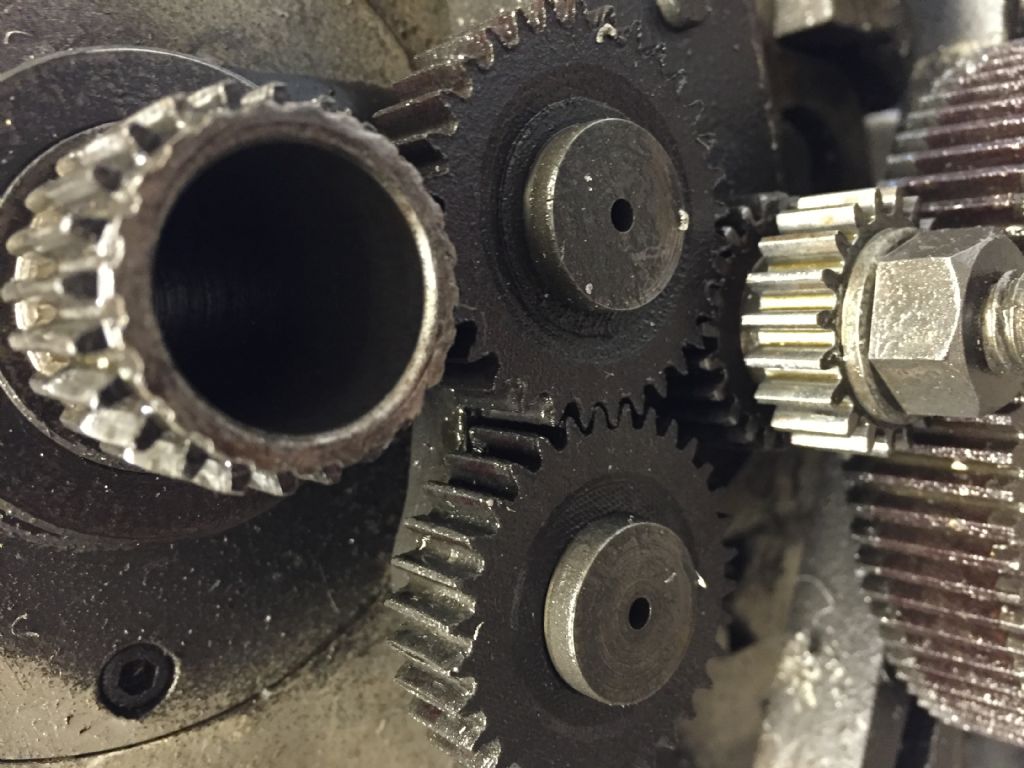

I can't really tell from the photo but the gear on the end of the spindle looks ok to me. Not sure why but next to the tufnol gears the teeth always look shallow / less sharp. While Michael thinks it's a design fault and could be right having been on the yahoo boxford group for a long time now I've not noticed anyone having problems with it. Maybe because it's heat treated steel like the rest of the spindle. A better photo of the worse looking teeth would help. Hard to tell from an end on shot but I expect they are ok.

As strange as it may sound tufnol gears are known to outlast metal ones when in contact with them. They use the tufnol to quieten the train down.

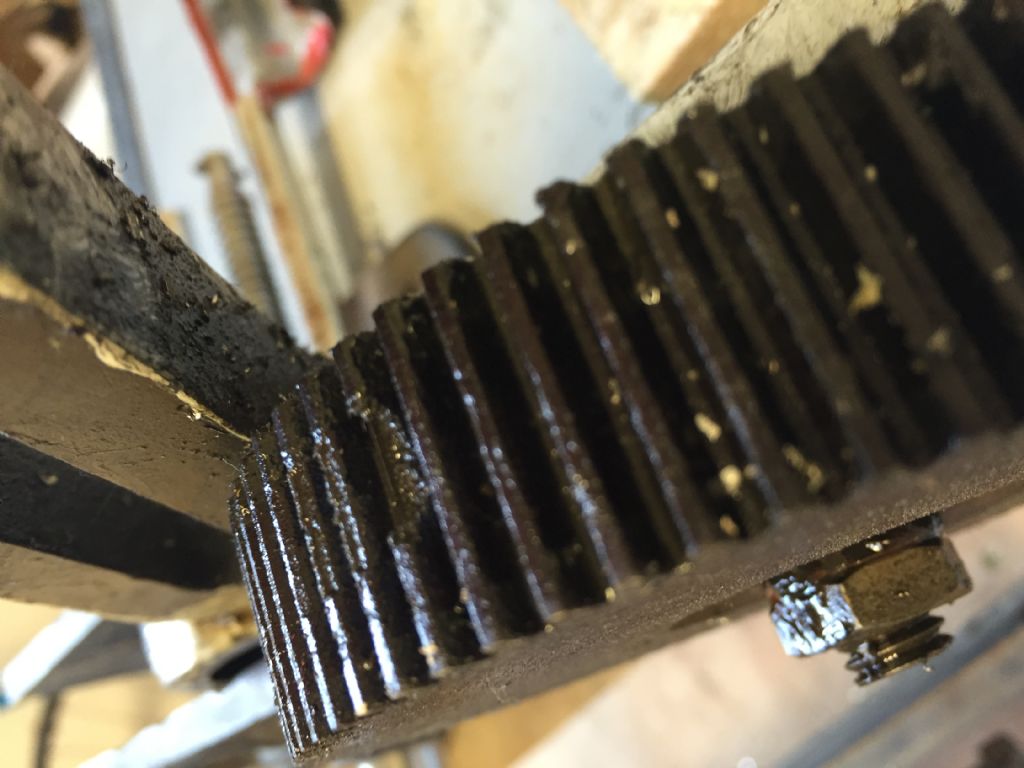

The 80T looks like it has a tooth more or less missing. Best not use it as it is likely to damage another. That sort of thing can happen for all sorts of reasons. I wonder if some one has screw cut into a stop on the bed. I theory it can happen if the mesh is set way too tight. That may explain the broken teeth in the gearbox as well. The newer lathes of this shape have a different power feed arrangement and that can be run into a stop without any problems. It's easy to tell if the lathe has that. There will be a slot running along the leadscrew and a feed tension adjustment knob sticking out of the saddle.

I wouldn't be happy with the gear with a bit of the top missing but one way of telling if it's likely to be ok is to watch what happens as it meshes with one hand holding one side of the train and the other the other to provide some tension. You'll be able to feel if it meshes cleanly in that area or jumps etc.

I don't know if you have joined the yahoo boxford group but it may be worth while. Some one may have a spare 80T and unlikely but some one may have the other gear as well. There are also generally boxford and southbend gear on ebay. It can be worth asking one ebayer – theplaneironshop othewise known as

**LINK**

Many of the model engineer type used machine tool sellers may have them.

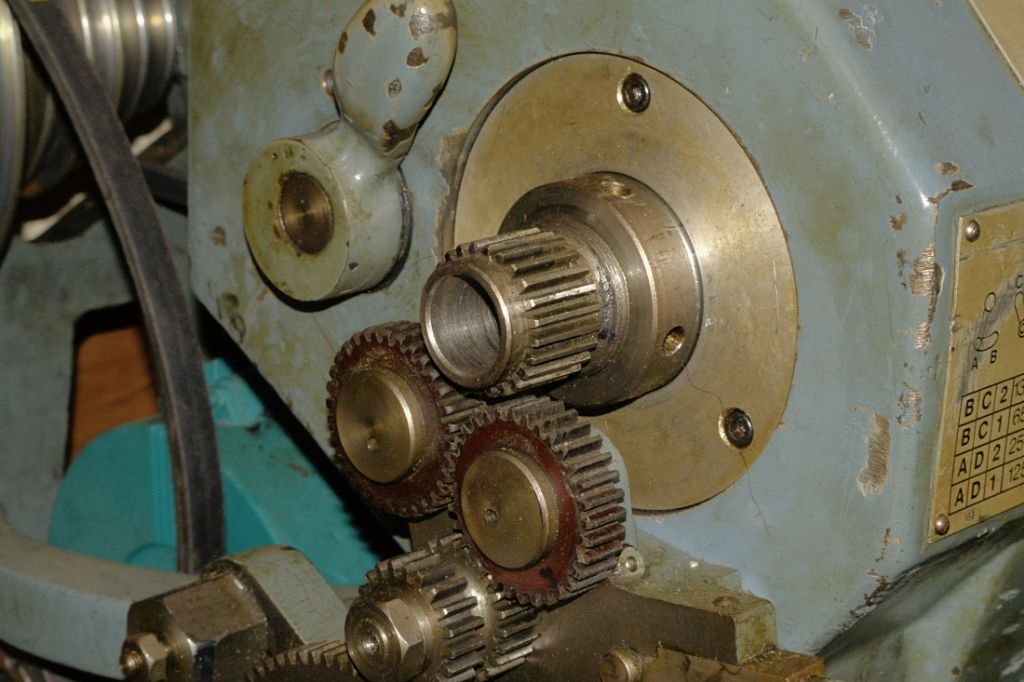

One thing for sure looking at the photo's all needs a really good clean and fresh oil before you use the gear train.

John Ward can be rather hard to get hold of. Visiting is one option if you are close the other is the phone now and again. Great bloke etc but he's often hard to get hold of and may not answer emails or reply to messages. He probably gets lots. Boxford will soon tell you if they have parts available.

John

–

Bazyle.

Bazyle.

The browny tinges are photo effects from a residual oil film that seem to have been augmented by a new strip light I fitted recently.

The browny tinges are photo effects from a residual oil film that seem to have been augmented by a new strip light I fitted recently.