I would have thought that they need to be very close, I've never blued one to find out though.  Maybe I should.

Maybe I should.

Suppose I could angle the head or use a sine table really. I'm not sure how a dro helps. Need to think about that. Others would probably be interested. If it's the step method and then blend in I might be more inclined to set with a vernier protractor and fit by hand if needed. Off the top of my head if done the right way table errors wouldn't matter. Not sure but sounds feasible. I'd guess a decent V block might do it too.

Suppose I could angle the head or use a sine table really. I'm not sure how a dro helps. Need to think about that. Others would probably be interested. If it's the step method and then blend in I might be more inclined to set with a vernier protractor and fit by hand if needed. Off the top of my head if done the right way table errors wouldn't matter. Not sure but sounds feasible. I'd guess a decent V block might do it too.

My boxford centre line height from the top of the compound is 1" give or take a few thou. As that's one Myford made boosting the the height of there normal one looks like Myford 7's are 5/8". As 5/8 is more or less 16mm I don't see why one isn't made for these tool posts as on the face of it the part that actually carries the tool could be 5/16 thick top and bottom. The usual odd 0.225 tool support bottom thickness of the normal tool holders would be fine and maybe the top would have to have an odd shape to give sufficient thread for the screws but that isn't much more than the bottom at circa 0.227 on standard holders. Actually the holders seem to be so close to 16mm I have wondered about opening one out rather than milling a bit off the boring bar off.

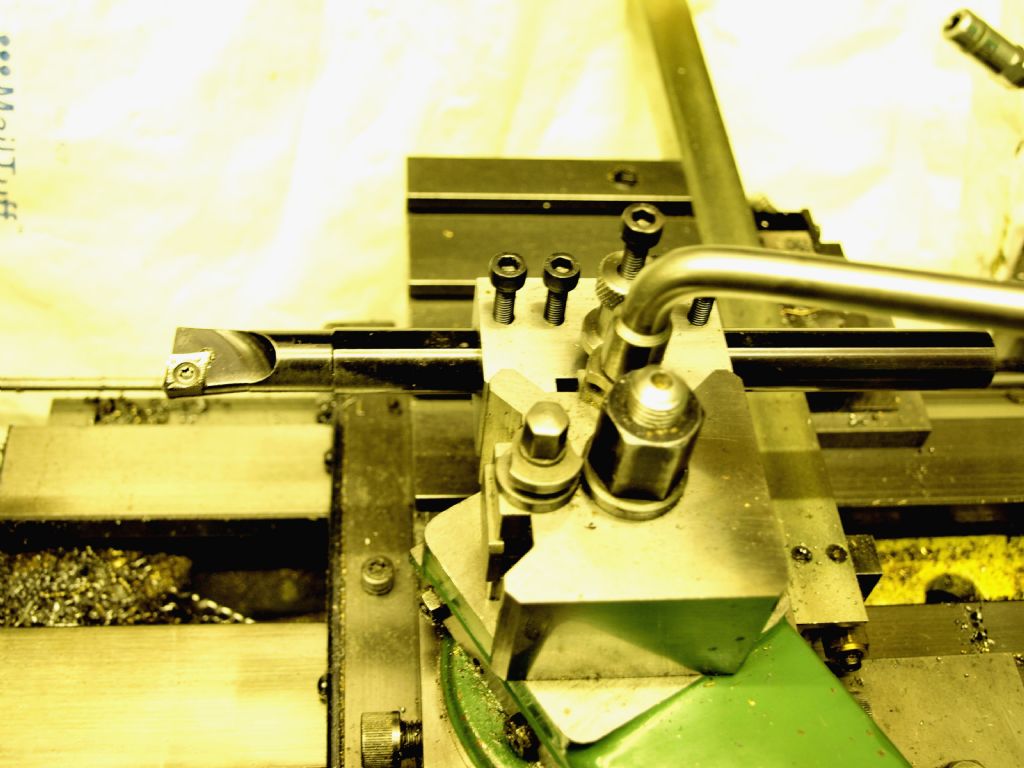

In terms of chatter i usually find it relates to the wall thickness of what I am boring and is reduced by using a heavier bar but will still happen at some wall thickness. It also depends on how the lathe is set up. Any play anywhere will make it worse. That to some extent can be taken up by taking heavier cuts or using a coarser feed which isn't always possible so it makes sense to adjust things as well as they can be. When it comes to flex in the tool holding area it would be interesting to measure it. I never have. In relationship to the compound and the top of the cross slide. I think people would be surprised how little it is even in the case of the heavy cuts posted recently – not the crap finish ones though as that will cause vibration. The cross and compound are likely to have to be set properly. It usually isn't going on lathes I have bought. Sadly headstock bearing can add to play as well but the work deflects instead.

Actually years ago I bought this rather large drop forge billet intending to use it for tool holders – dam thing is a bit too small.

John

–

Anonymous.