Urban (or should that be Workshop) myth. More that it shouldn't be below centre height. Especially on the small(er) jobs and small machines folk like us use.

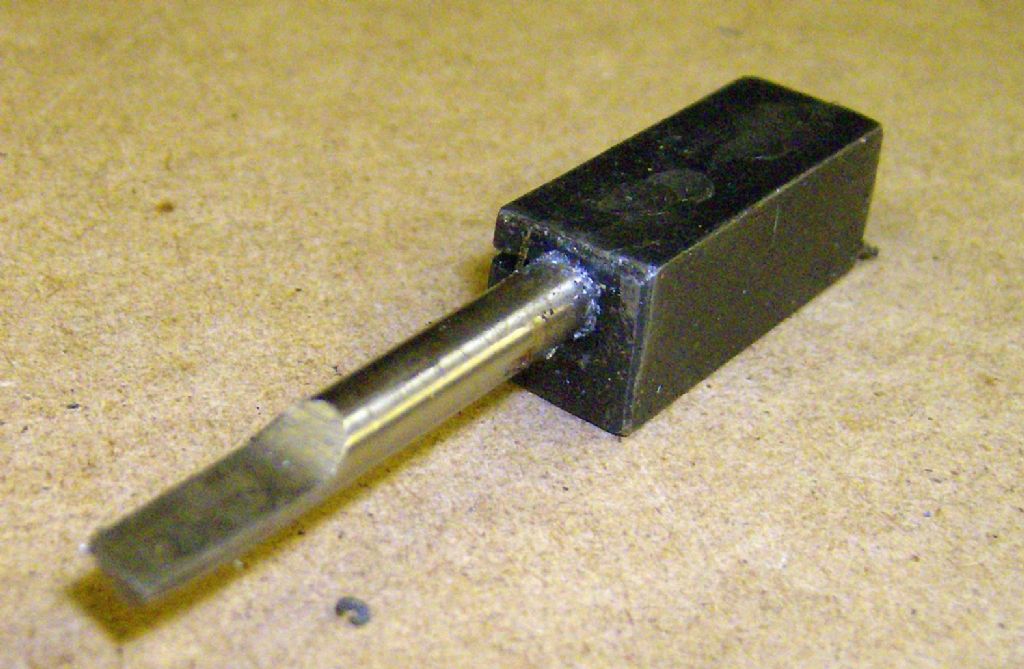

The important thing is that the tooling be really sharp, have sufficient front clearance not to argue with the side of the bore and be of the correct shape. For small jobs I did some drawings of the front clearance needed which are great help. Compared to ordinary tooling the rakes needed are huge and my instinct at least is always to leave too much metal on when grinding. Shape is important as its easy to end up with something that will push off or drag in if you aren't careful. Don't assume the basic shape on the as bought tool is good. Assuming you have the clearances needed to get the tool into the starter hole you are much more likely to have trouble from drag in or push off than anything else.

Always remember that a tool must be made to cut if results are to be reliable. Shaving off half a thou at a time is absolutely not how its done and if you regularly have to resort to this its time to take a good look at your sharpening skills and material stocks. Unless you are working with "incrediblyhorribletanium" from unknown source donations, scrapyard finds and odd leftovers twenty thou is the sort of finishing cut you should be aiming for with good sharp tooling. Under ten is usually asking for trouble. One day I shall steel myself to take my stock of "incrediblyhorribletanium" to Mr Scrappy despite it being such useful sizes and spend some money on decent stock stuff.

The above centre height thing come from big machine practice with big tooling, big jobs and big cuts. Shipyard, railway and similar shops where you can reliably put a few thou bend on a bar or tool and expect it to hold steady under cutting loads.

Clive.

Nick_G.