Posted by Stub Mandrel on 26/10/2012 20:20:13:

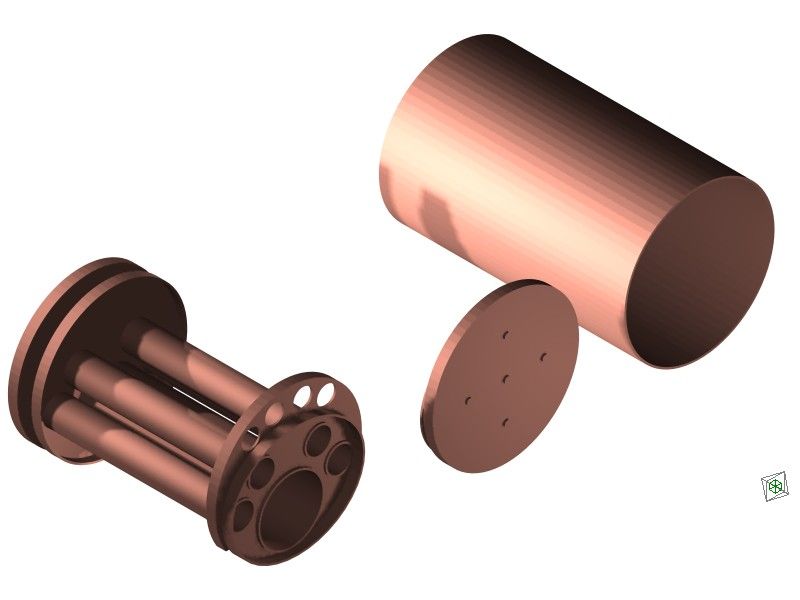

I have a 2 5/8" seamless copper boiler tube, 0.041" thick.

Using Tubal Cain's formula thickness=pressure x diameter/2xUTS for a seamless tube

Safety factors are built in to the above

Neil

Niel

I concur with what Eddie has said.

The formula you give is from the standard formula for hoop stress in thin cylinders where stress = (pressure x shell radius) / shell thickness.

I was very surprised see UTS in your formula.

Using UTS does not provide any safety margin and to my way of thinking is more akin to burst pressures calculations.

As Eddie indicates, the safety margin is in what you use as your design stress, so thickness = working pressure x dia / 2 x design stress.

For example, pressure vessel codes typically use a design stress equal to material yield stress/1.5 for steel at ambient temperatures.

To check under hydrostatic test, you could use your test pressure and design stress of say 90% yield stress for steel. Eddie indicates that for copper a stress of 5000 psi would be suitable to use at your test pressure.

Unless there is something in Tubal Cain's book I am missing. hope my ramblings help.

Nigel

Edited By tractionengine42 on 27/10/2012 10:38:51

Neil Wyatt.

Neil Wyatt.