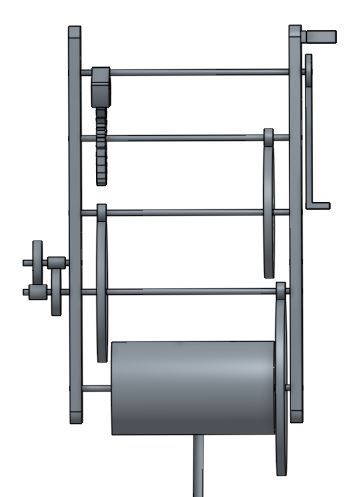

Slowly progressing with my drawings. At the same time as designing the clock, I am learning CAD for the first time. I am using Onshape which seems generally to be all right, but seems to do odd things at times, for no apparent reason. I had to draw the pendulum suspension block several times as part way through adding other parts to the assembly, the block split into its components parts and appeared to fall apart.

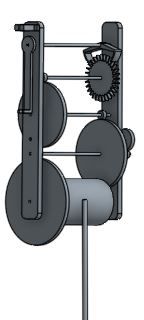

The width between the frames is currently arbitary and will be set later once I have worked out hw large the winding barrel needs to be. Using the idea of a looped rope with pulleys, I should be able to get seven of eight days running time from a four foot drop.

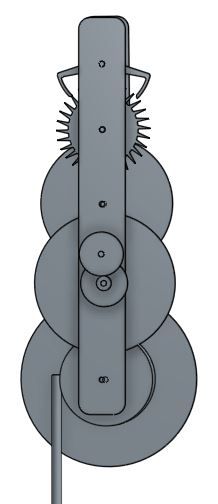

I have settled on the following gearing. It may not be ideal, but it all seems to fit and look generally fine. I know that it still uses ten leave pinion in the train, but I am struggling to devise a better ratio that fits together.

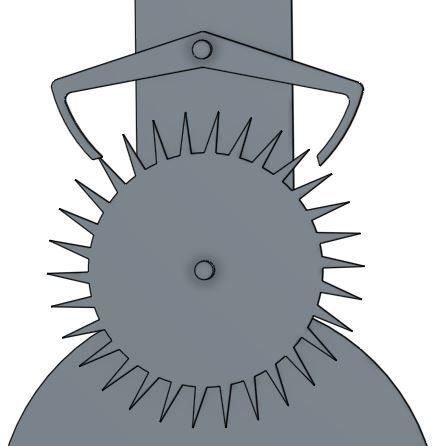

30 tooth escape wheel followed by:

12:90

12:96

12:120 for the barrel wheel

I have 10:30 and

8:32 for the hour and minute hands.

As mentioned before, the frames are merely shown to hold the wheels and aroburs in place and are not the final design or size.

Michael Gilligan.

Michael Gilligan.

Maybe some one close could go and take a good one.

Maybe some one close could go and take a good one.