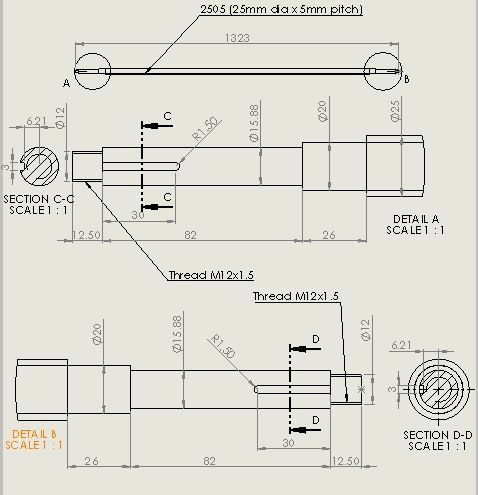

IanT – yes, just at the ends.This is from one of the drawings (for the X-axis). I think I paid $10 for the machining of the X and Y balllscrews. Can't recall if that was each or total but it was a bargain either way. You can't really machine keyways where the ball threads are.

I made a transfer arbor for my Z-axis ballscrew which I bought a few months before the X and Y so I could machine the ends myself. I also had to machine down the hardened flange on the Z-axis ballscrew. If you need to remove the ballnut, it could be tricky with some designs, so you should consider how to make and use one of these arbors at the design stage. I'm not planning to remove the X and Y ballnuts at this stage but that may change….

Unless you buy from the US, ballscrews tend to be metric and generally come in 12, 16, 20, 25 and 32mm diameters. The most common pitches are 4, 5 and 10mm, although there are larger ones if you look around. 5mm is the same as the original pitch on my metric Bridgeport clone and I could see no obvious reason to change it. I also downsized from 32mm acme thread to a 25mm ballscrew. If you look at the load specs, 25mm should be more than adequate.

BTW, if you are made of money, you could order from Misumi who make configurable ballscrews (and many other components). You can customise the design, download the resulting CAD file and get it made and delivered. No, I'm not made of money but it's an intriguing business.

Murray

Muzzer.