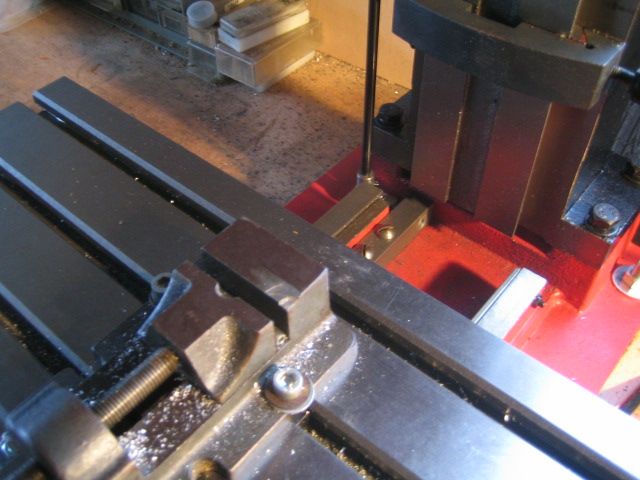

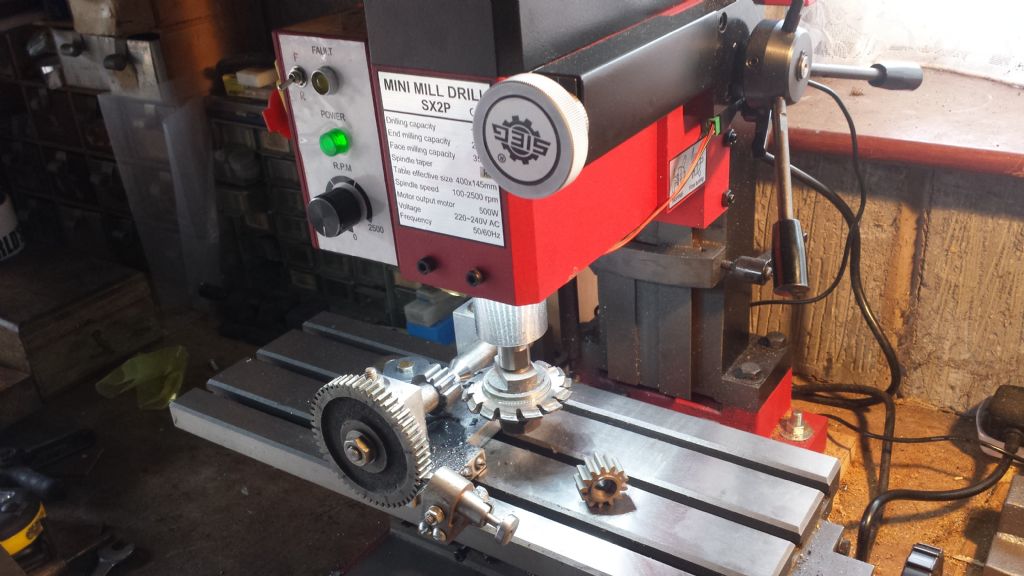

In the month since the last post I have managed to fit the DRO and the X and Y axis scales and heads. The display unit on it's bracket was simple enough on the right hand side of the machine, but both X and Y brought issues to resolve. This is the X,

which required two holes in the saddle with the column immediately behind, not possessing a right angle drill and not really wanting to buy one I acquired a cheap right angle attatchment from Screwfix, pretty horrible thing but at £9.93 by far the cheapest option, it sufficed. The Y was not without a challenge,

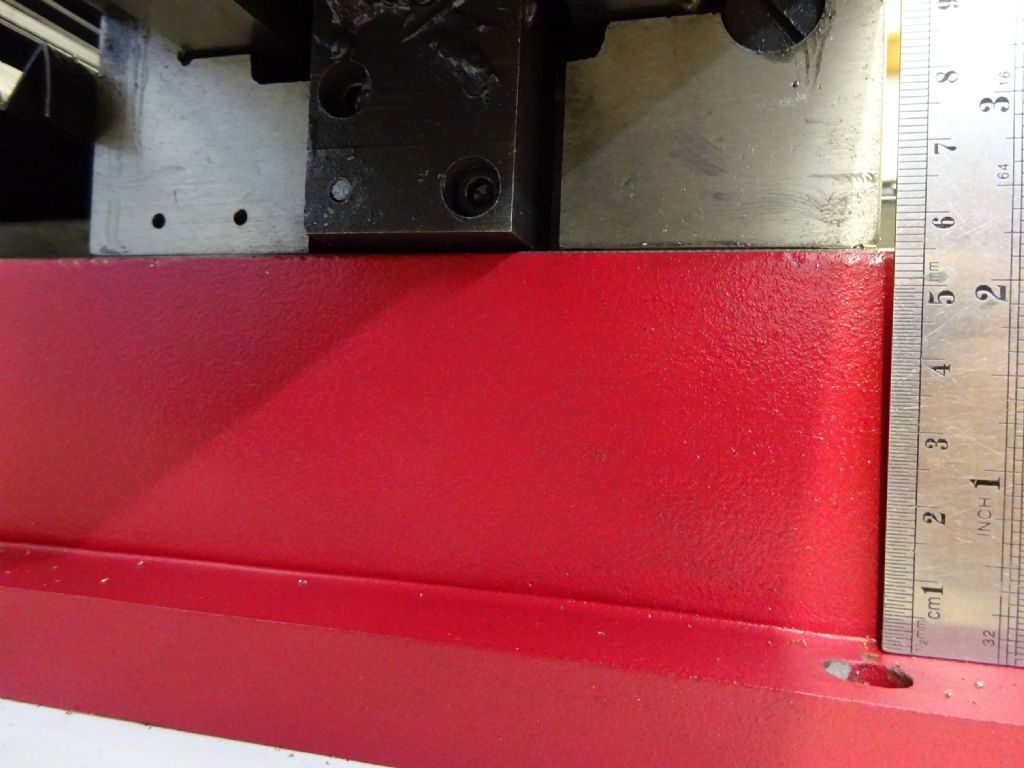

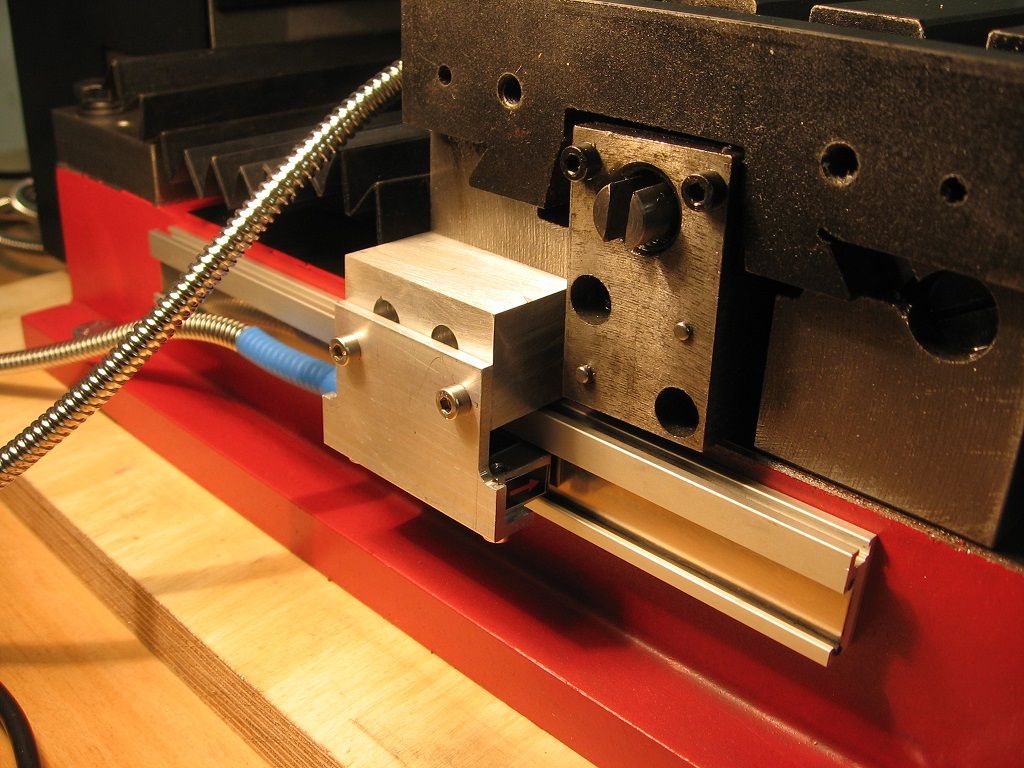

the sides of the base are at 2.5 deg from perpendicular as best as I could measure so the mounting block required a similarly inclined face, I admit to three goes to achieve this with various set ups, fortunately the stock was well oversize. I got there in what should have been an unchallenging simple process, but I did struggle a bit in my head. My biggest fear was that through my own cackhandedness snapping off a tap, that would have been a disaster.

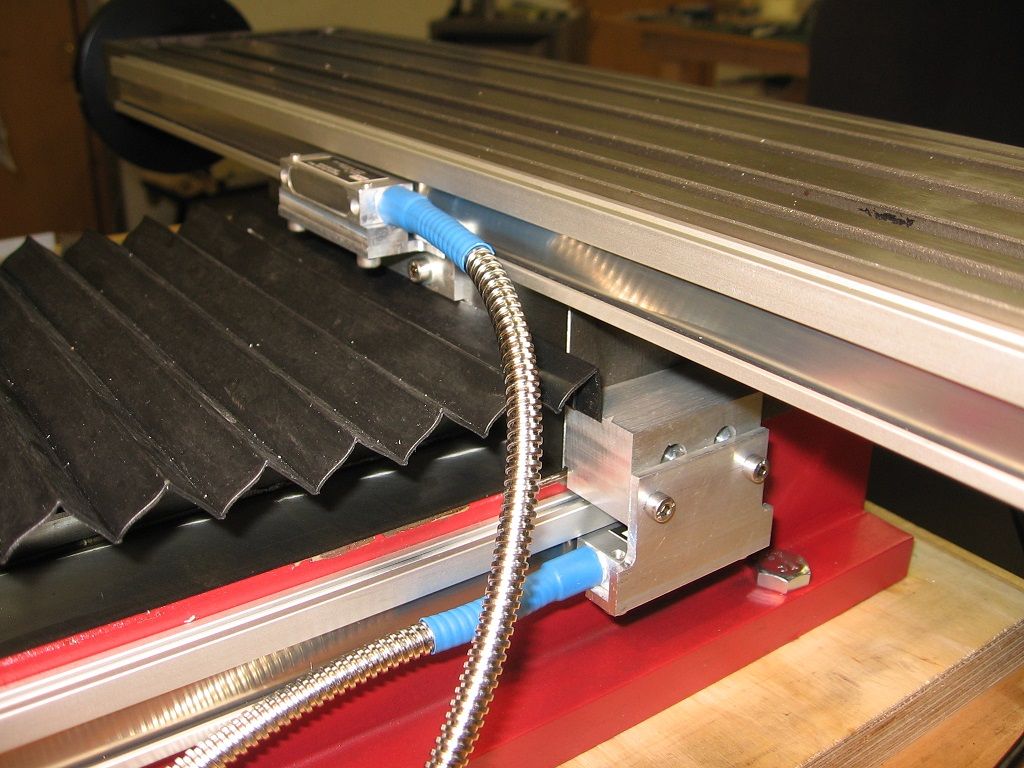

One interesting and for me annoying part of the Allendale package are the supplied mounting brackets, ideal for a Bridgeport but way oversize for an SX2.7, also whilst the scales are perfectly fine, if you couldn't utilise the offcuts on another machine then a lot is discarded. Having said all that, given that it is a no contact magnetic system it's forgiving, I reckon optical scales could be a major pain.

Regards

Martin

Edited By Martin Shaw 1 on 01/01/2019 18:59:21

geoff walker 1.