Hi All,

Well, I didn't expect quite that number of replies. So again many thanks for all answers. All read and greatly appreciated. Perhaps in some areas my description was lacking somewhat as its always difficult when describing things on forums. To try and put some minds at rest, for those still wondering, I will try and provide a more exact explanation for completeness.

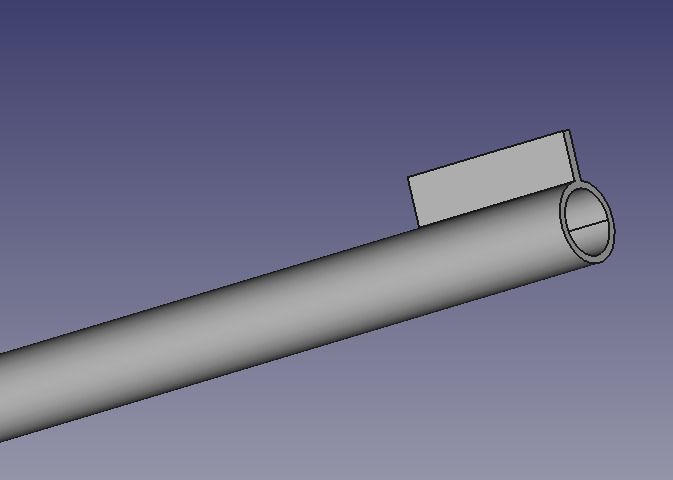

I have a 2 inch diameter 5 meter long Aluminium tube approx 1/4 inch thick – think of Aluminium scaffolding pole

I need to fasten a piece of aluminium bar to its surface, i.e two the surface of the 2 inch diameter on the 5 meter length. The aluminium bar measures 150mm Long x 40mm high x 8mm wide/thick

I was referring to bolting through the 2 inch tube into the bar, the interface with the bar is onto the 8mm face of the aluminium bar, so as a few people have pointed out not much meat left in 8 mm thick Aluminium bar after either tapping through or making clearance holes and a nut to secure it via the 8mm face/thickness. Though there is some 40mm height of material. Hence the need perhaps to go to 10mm thickness, or reduce the bolt diameter.or both smaller bolt and 10mm material. Unfortunately, I am unable due to other restraints, to increase the bar thickness above 10mm.

I hope that clears up any discrepancies. From the kind answers provided I think I will try and tap the aluminium bar with two M5 threads, one close to each end of the ends 135mm apart in the 150mm length to accept stainless bolts with about 18 – 20mm thread engagement in 10mm thick aluminium. All the aluminium is 6082-T6.

I hope that will be job done. The bar provides an interface bracket for another aluminium tube 30mm diameter, which forms a horizontal joint in a horizontal Truss Beam. ( I know thats as clear as mud now!) Will give it a go and see what happens under some crude testing. Its not a critical truss beam, so no life threatening disaster should it fail.

Many thanks, and again very much appreciate all the replies

Gary

JasonB.

JasonB.