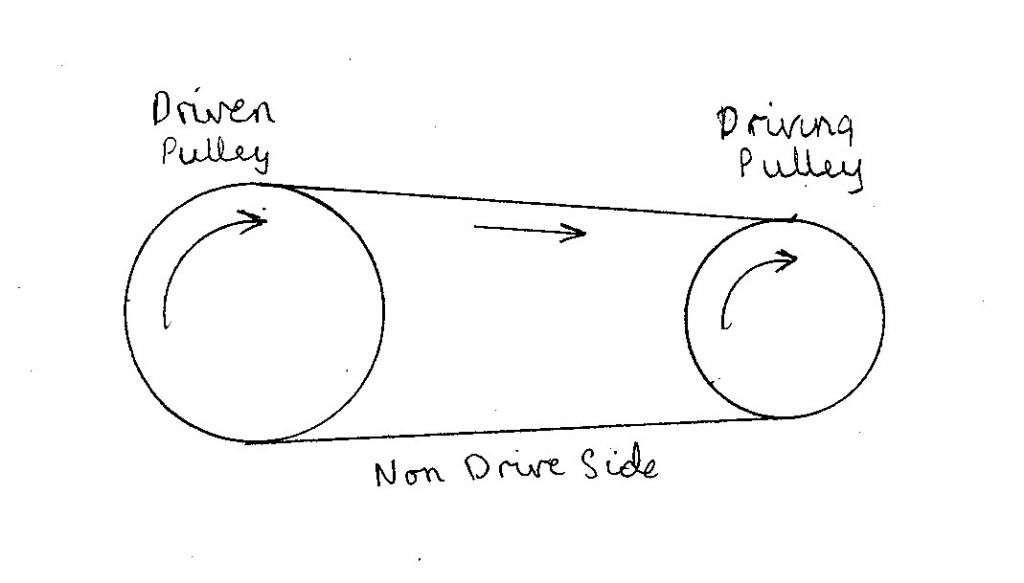

I once build a minature vehicle with 4x castor pump up wheels(with tubes) that look like normal tyres. Long story short it was strong enough to pull a car, and one person could not hold it back, speed 0 up to 25Km/h, it used a suzuki waterpumpump overhead valve engine with a centrificle clutch of old brittish green lawnmover, then a V-belt to a 50cc motorcycle gearbox(tuff)(Piston removed), I could change gears back and forth on the fly towing trailors. From the gearbox it was chain driven to the rear wheels to a shaft with a V-Pully on each end then a short V-belt to eack wheen with machined V-Pulley. Now here it slow turning high torgue. No diff, I however played around with where to tention the belts with a jocky pully. The belts were cheap, the tyres expensive. Now out of this spring tentioning I manage to get like a slip effect going around a corner slipping the belt on one wheel to save the tyres.

Initially I bought a bag full of various belts. Now the interesting part started. I tested this on a friens farm, and soon one belt failed after 15 minutes of use, it just stretched from heat called manufacturer-X. Now it took me some two days then to put 2 & 2 together and figured it was only this one make of belt. The belts I settled for was then called Gates-High Power.. It was unbelievable how long they lasted=They looses some of rubber on the inside after many trips but never stretched or broke.

The next interesting part was at work. Our airconditioner(Huge motor using 4x belts} never gave problems in this regard, belts always lasted full service life. Then we start getting failures of belts lasting not longer than 3 months here, they stretch and fell apart literally. On inspection, guess what, it was the same manufacurer I used and discarded… I notified the aircon staff, and they stop buying these, problem solved.

So there can be huge differences between V-Belt qualities when varying speed and high torgue is involved

My experience with V-Belts.

Chris Mate.