Hello Zan,

Thanks for your email which alerted me to your post. You are right it has been sometime since I posted save for the initial issues on the change over.

Engine wise I have nothing to report but a lot has run under the bridge since last doing so. Hopefully I may be able to get back on to it in the Spring.

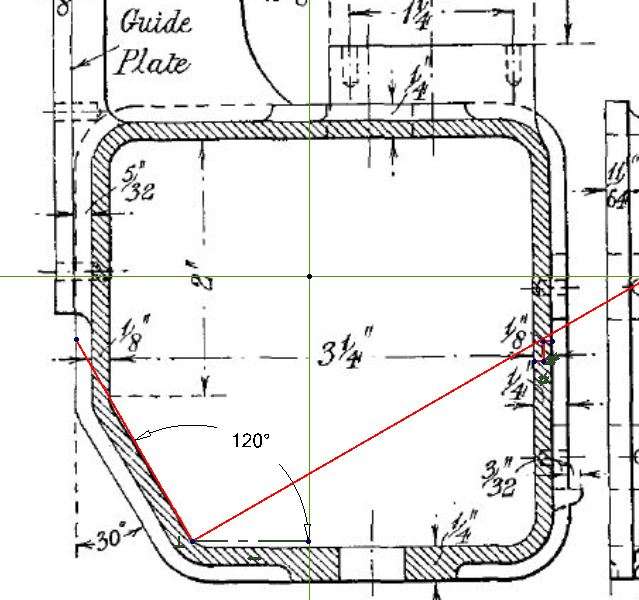

Re the condenser. I have to confess that initially I misread the drawing and ‘saw it in my head’ from the outset that the plates were recessed. The condenser body was milled to accept such before I realised that mistake. I did consider trying to reclaim it to as it should be but as with yourself, with no intention to run on steam, decided it wasn’t worth it.

As the design calls for, the tubes are soldered after the plates are screwed in place. One can only assume the plates would be sealed by some means too as once soldered they would not be removable. The cavities at each end in the covers which are only open to cooling water would then have a gasket to provide a seal. In that case once you commit to fixing the tubes by ‘soldering’ you may as well commit to doing like wise with the tube plates. Obviously far too much heat would be required for that so standard JB weld or similar springs to mind as a suitable means. A paper or liquid gasket should suffice for the covers which is what I shall do on mine. I ran Loctite Bearing Fit around the edges and around the tubes, not so much to seal but to secure.

Though I have not made any progress on my version the year has been full with other matters. I have now consolidated my 14 x 14 workshop into 14 x 7 and screened it off. ‘Compact and Bijou’ I’m quite happy with the smaller workshop outcome and it will serve more than enough for anything I am likely to do in future. The larger mill has been sold and currently I’m working on the area left to become a ‘clean’ one.

I have hit some health issues this year, nothing serious but enough to have a detrimental effect at times but I’m still maintaining my interest in building and flying control line models and of course plastic modelling. I have several matters to tie up in that direction but I do intend and really hope to be able get back on to the engine next year.

Wishing you, and all that look in, a Happy Xmas and here’s to a good and happy New Year

Ramon Wilson.