Posted by Martin Shaw 1 on 24/03/2019 15:27:50:

…

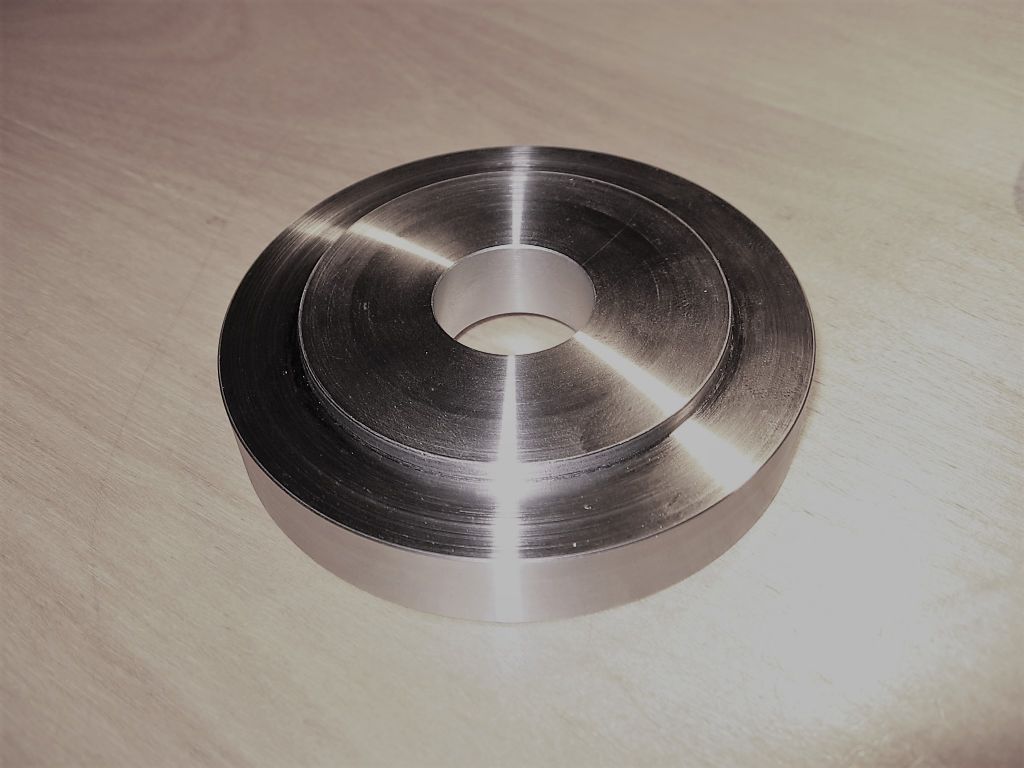

It did generate a fair amount of heat and at that speed I suspect the insert life might be shorter than it need be, I'll put that down to learning. Has anyone any thoughts about cutting oil, my reading on the subject suggests either flood cooling or dry. I have another backplate to do in due course so I will try that at a lower speed.

Regards

Martin

Ideally with carbide and steel you're looking for smoking hot swarf flying off in small lumps like shrapnel. Ribbons of swarf are bad because they tend to go under the cutter and spoil the finish – this may be why your photo has a somewhat streaky finish. Also, ribbon swarf forms into balls that can be flung in your face by the chuck. What's needed is an even deeper cut, one that causes the ribbon to break into blue chips.

I'm not recommending it though! Apart from the lathe having to be fast and powerful, and there's serious risk of overdoing it on a hobby machine, the effect of sizzling swarf chips on the operator is downright unpleasant!

Conventional wisdom, which seems reasonable, is that carbide might shatter when heat-shocked, which could happen if you dab coolant with a brush or drip it on. So you either run carbide dry, or flood it. I'm not so sure – most of the carbide I use has been tough stuff, and I have dabbed work to improve finish without causing an explosion!

But I strongly encourage experimentation. With carbide, so much depends on the material, machine, depth-of-cut and the insert I hesitate to be pedantic. Carbide inserts have many advantages, but they work best when cutting conditions are in the zone. Provided it's kept in good nick a big advantage of HSS tooling is getting a decent finish is more tolerant of operator and machine limitations. It's also better, I think, at removing very fine layers of metal, which suits homing in on dimensions.

Dave

Edited By SillyOldDuffer on 24/03/2019 16:17:07

Martin Shaw 1.