I've confirmed there is a problem. I took another 0.2mm off the face last night and got a similar result. Locking the top-slide properly nearly halved the error, so that was part of the problem, but locking didn't eliminate it.

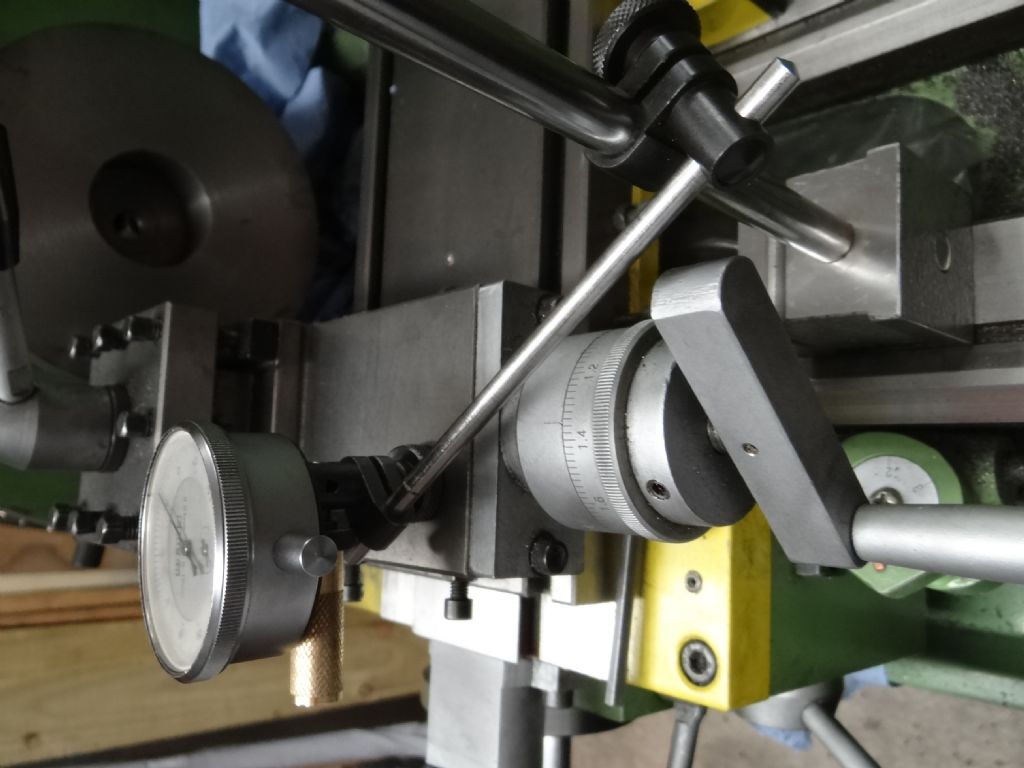

The test I believe confirms the error is the amount of visible light appearing under a straight-edge. The straight-edge shows the lathe is cutting concave (which is correct). Assuming I'm applying it correctly, a DTI shows the error to be excessive (about 0.08mm over 50mm) . For comparison Schlesinger's target for facing is 0.02mm over 300mm. (Thank you Michael for that information.)

I need to finish the job I'm doing and then investigate further. At the moment the lathe is filthy (cutting cast-iron), and everything needs a good clean before jumping to conclusions. Sleeping on it, I thought of a few more checks. I don't think they're likely to be loose but I need to confirm the tool-shank is clamped firmly to the top-slide and that the top-slide is tight on the saddle.

After that, I shall proceed as per Perko7, thank you for the suggestions.

As an observation, I've seen dozens of posts discussing Rollie's Dad, tailstock and other 'along the spindle axis' alignment tests, but I don't recall similar interest in facing accuracy. Perhaps flat facing isn't critical for many jobs, provided concavity prevents rocking. Even so, has anyone else measured their lathe's facing performance?

Dave

PS Certainly not ignoring Pete Rimmer!

Edited By SillyOldDuffer on 13/08/2018 10:20:28

SillyOldDuffer.