All very well saying sell it, but if they are not useful then there will be no demand for them….

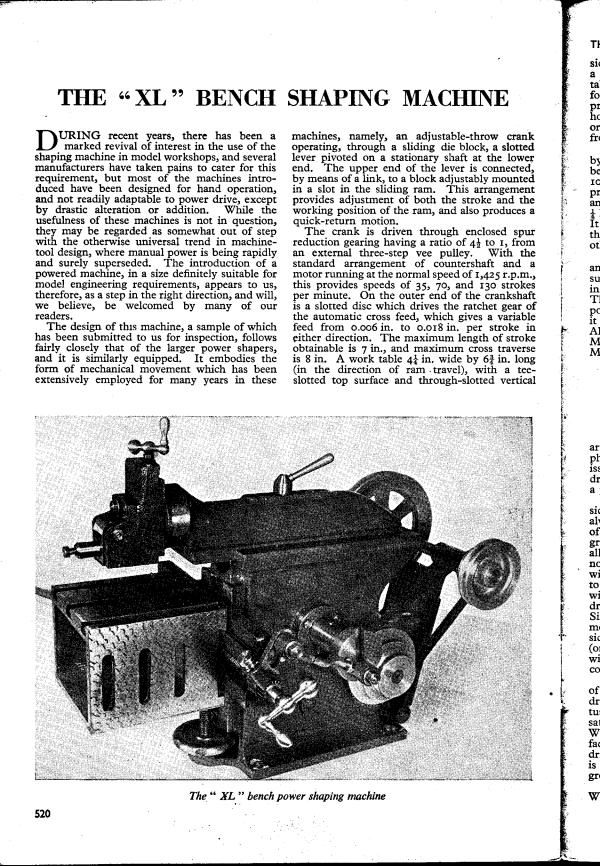

Actually for an amateur they are quite a useful machine to have. They do not compare directly to a vertical mill…the more appropriate comparison is to a horizontal mill. Now, I have an 18 inch Alba which cost me $350NZ complete with vice. It can plane a flat surface up to 18 inches each way, with a surface finish which a professional machinist thought must have been surface ground. Supposing I had a horizontal mill capable of milling a surface that large, what would it cost me for the milling cutters to put on the arbour to do that width? I think the answer would be a lot more than $350!!! But I can do the job with one piece of 3/8 tool steel. OK, it takes time, which is why the professionals don't bother with shapers anymore. But time is not such an issue for me or most other amateurs, and anyway with a bit of care I can have the job running on the shaper while I do something else on the lathe.

They are also more versatile than they are usually given credit for. Dovetails are the obvious extra, and with a left and right hand narrow angle tool you can make inside and outside dovetails to any angle you like. (I have encountered them in both 55 and 60 degree angles, and no doubt there are others.) With a mill, you end up buying fragile dovetail cutters that you may only need for one or two jobs.

But there are more things you can do. Back when I used to write for Model Engineer, I did a couple of articles relating to shapers…one was shaping between centres, where you mount a pair of centres parallel to the axis of the ram, (on the table) and can then produce complex shapes that combine sections of arc with flat portions. I used this to make a section which I then sliced up to make eccentric straps for a Leak compound engine. You can also do curves in another way which I described. This lets you do large radii, eg from some minimum, probably about 5 inches with my lashup, to infinity, eg flat. I used this to do the expansion links. OK, a mill with a rotary table is good for this, but a lashup of steel bar and plate on a shaper makes an interesting alternative. If you do have a rotary table, as I do now, you can do other interesting work like put slots or flats on a job at arbitrary angles.

If space is a consideration you must choose your machines with care, in which case a lathe would be the first choice and a vertical mill/drill probably the second. But if you have the room to accommodate it, a shaper is quite an interesting thing to have. Having more space than most, I had four here for a while, in four sizes. The 14 inch Alba has now gone to a home where it will be appreciated, and where the flat belt drive with fast and loose pullies will be an asset rather than a disadvantage.

Another consideration of course is the type of work you do. If you are building stationary engines, the ability to plane the flat surfaces just as they would have been done on the full size engine is an advantage. None of those horrible curved marks that a vertical mill will leave!

John

thaiguzzi.