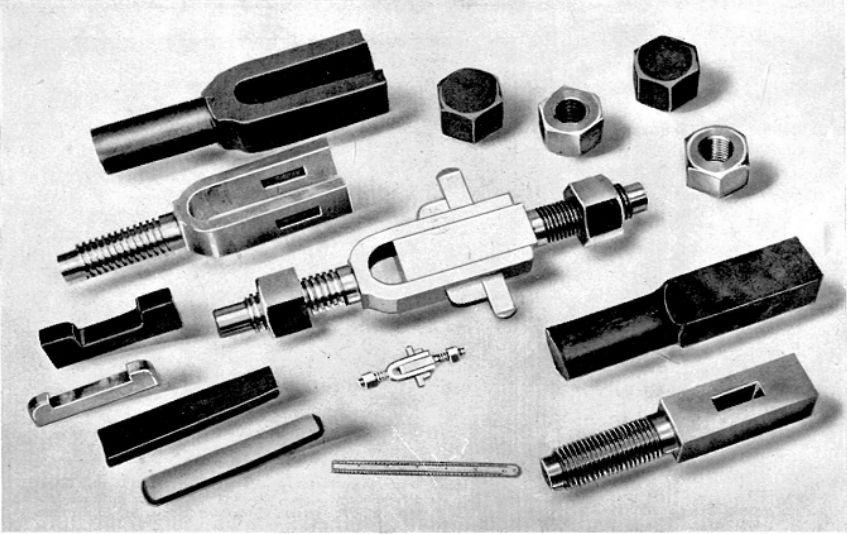

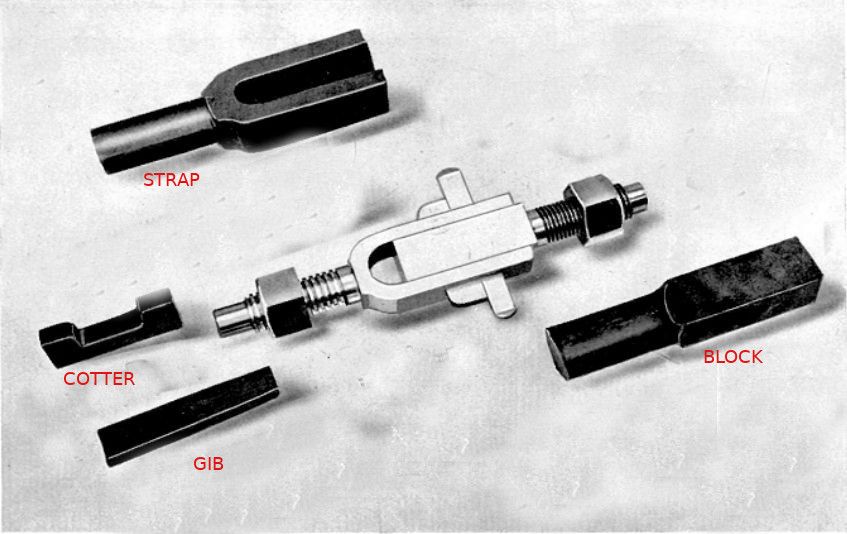

They're used to connect rods together that are only subject to axial forces. Normally a block is made on the end of one rod and the strap on the other.

The rod and strap are both traversed by a slot. To assemble the fastener, the block and strap are aligned and the 'u' shaped gib inserted so that it's ends lock on the strap. Finally the wedge shaped gib is hammered into the remaining gap to lock the whole together.

The advantage is that the joint can be assembled and dismantled quickly whilst keeping the parts in the same relative position. Once common on locomotives to connect rods to cross-heads and elsewhere to fix rods to stationary parts.

Your picture (which I've decluttered) is the first I've seen with screw-threads. Possibly this is because they are apprentice pieces rather than the real thing.

My dad joined the RN to train as an Artificer at the end of 1945. He never mentioned any practical exams on entry. Possibly the RN dropped the 'make it with a chisel' test because WW2 didn't have time to waste when most warships were fitted with turbines or diesels. Possibly because it was moved down the curriculum. (Dad was invalided out after a year due to a rugby injury. Near miss for me – that's how he met my mum!)

Dave

Edited By SillyOldDuffer on 22/11/2017 17:01:11

peak4.

peak4.