Posted by Arthur Goodwin on 05/01/2021 22:18:02:

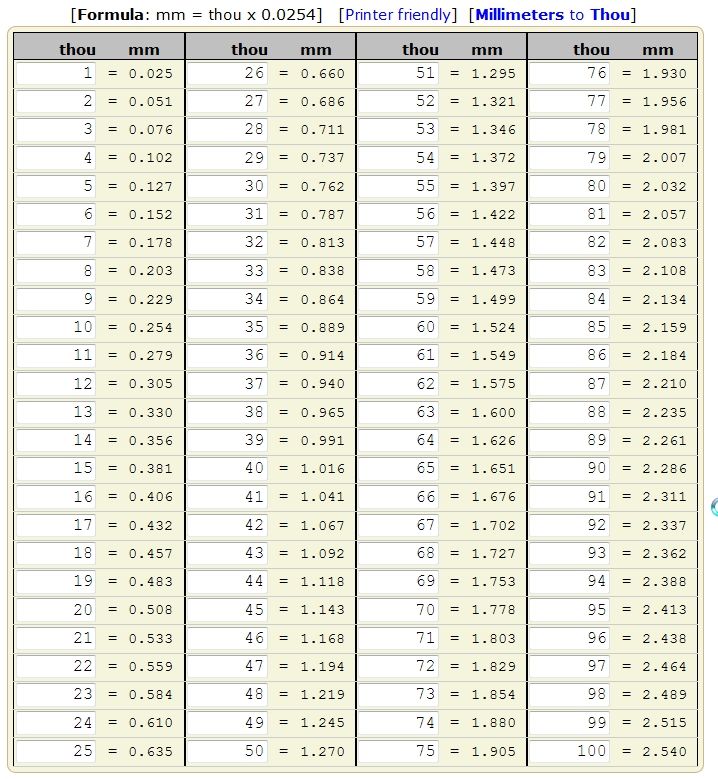

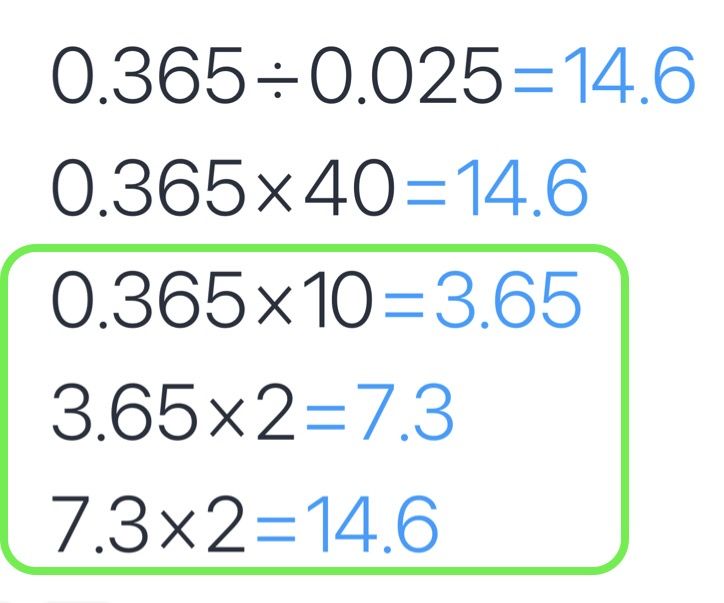

I have a Denford Viceroy with metric leadscrews and graduations of 0.025.

I work with metric drawings but my stumbling block is knowing quickly how much cut is needed to get to size without reaching for the calculator

I got fed up with the mental gymnastics and made a new set of leadscrew collars with 0.02mm graduations! (Chinese mini lathe)

I made new collars because I wanted to make them re-settable / lockable, but you could just make up graduated sleeves to slip over the existing dials if you're happy with them otherwise.

The collars were made from aluminium. Graduations were made using a boring bar on its side and a pointed HSS tool; Indexing with a printed pattern glued to an extension on the spindle and numbers using a punch. I did anodise them afterwards and they're holding up well.

Short term pain for long term gain.

The remaining bug-bear is the 1.25mm pitch cross slide leadscrew. I can see me replacing it with a 1mm pitch one sometime.

Edited By Andy_G on 05/01/2021 23:52:23

old mart.