I have one – it’s a combo.

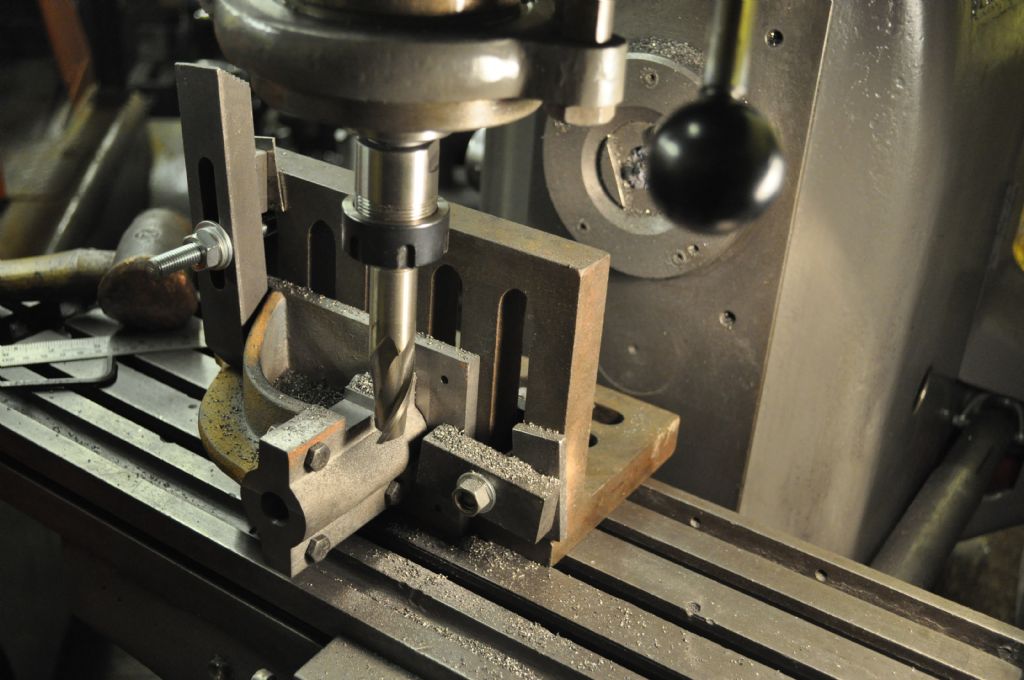

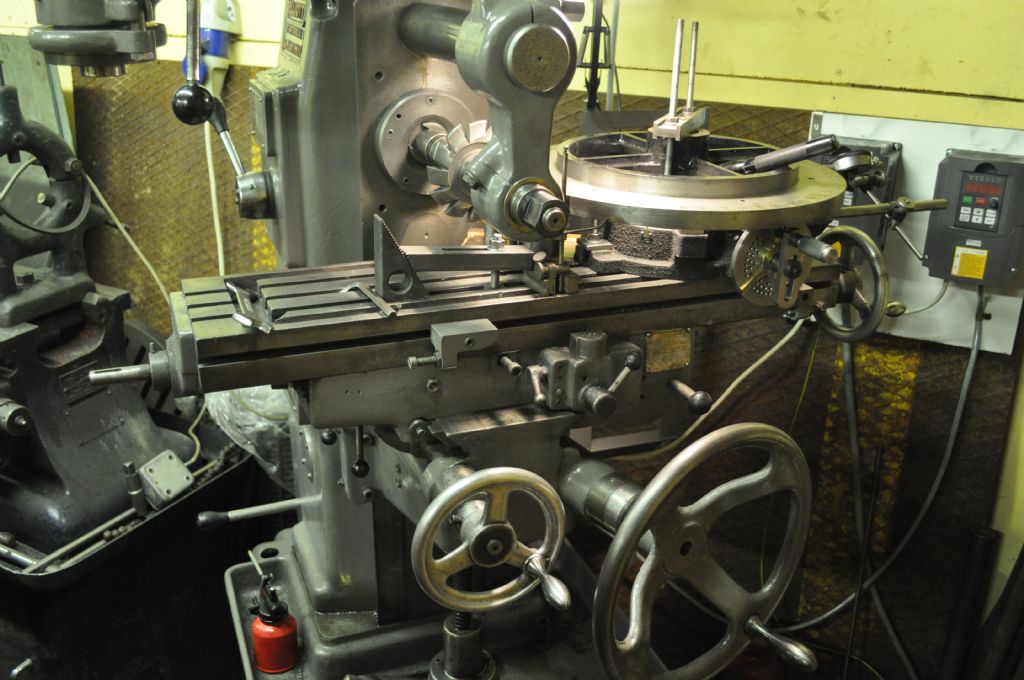

It is used more with the vertical head, but the horizontal is handy – when I can change the head!

I would like it in horizontal mode more often, but my other smaller vertical mill is limited in size (although it is handy for small parts).

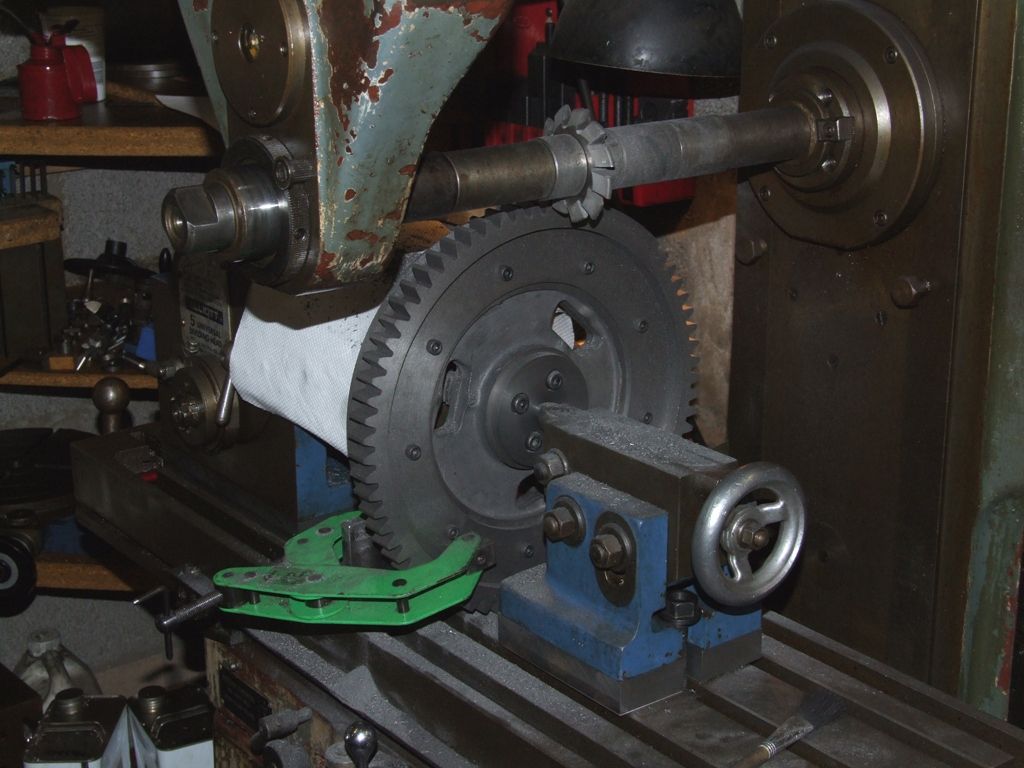

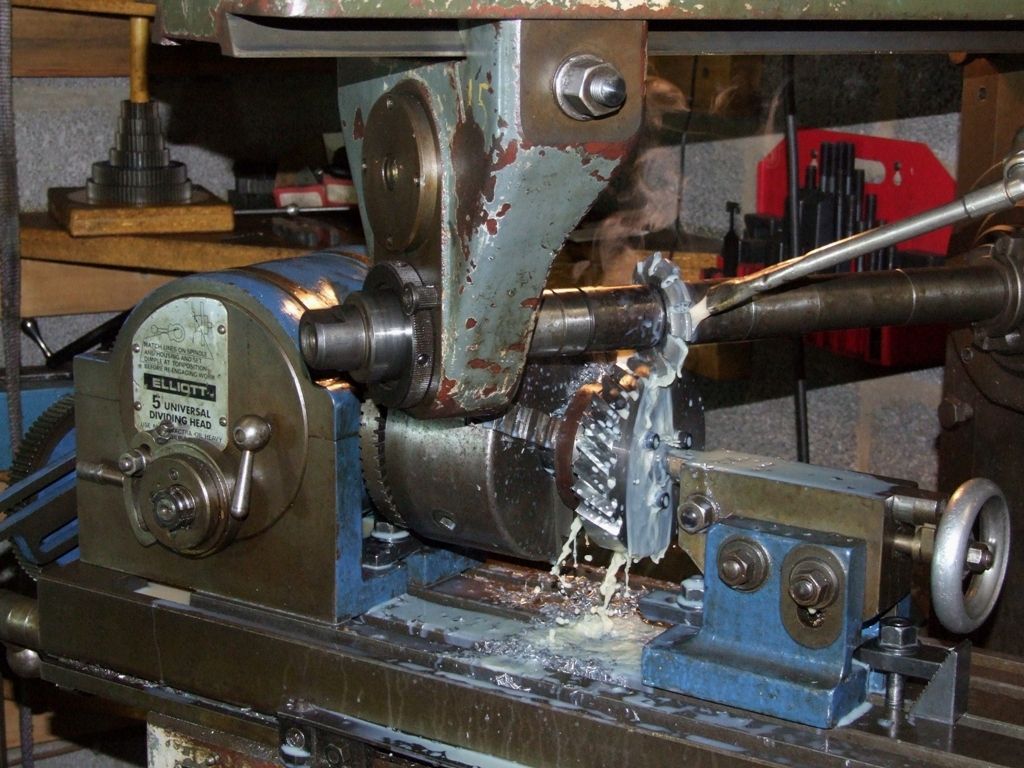

Small one is a Raglan and the other is a Centec 2b. So the horizontal is tiny compared to Andrew’s, but certainly not small when it comes to moving it!

Question might be what do you call small?

This member might be open to a deal for his mill.

**LINK**

Second hand cutters can be relatively cheap, but new are expensive. Don’t know about sharpening, but I expect that would not be cheap.

Machines tend to be more rigid. You likely would not buy a new one, so wear might be a problem.

Most things that a horizontal mill will do can be done on a vertical mill (reason why nearly all new mills are vertical type?).

Andrew clearly uses his far more than I will ever use mine (in horizontal). I bought mine because I needed a better mill, at the time. The horizontal with a vertical head was attractive for me. I would not change that view. It is big enough (well, almost) for me in horizontal but still limited for milling large parts in vertical mode. And it was British made.

A difficult choice if you are only going to keep one. If it is at the right price, trying it,and moving it on later, may not be too expensive?

Without knowing your current options and your needs, it is difficult to make a guess. Do you have a pillar drill, for instance?

Not much help, am I!

Howard Lewis.