I've had this 4Kw(5.5Hp) VFD with pendant for quite a while now, and been extremely pleased with it..

Having lived with a bit of hunting noise from motor/clutch area, believing it to be poor belt/pulley & length of belt combination origin.

However, of late I've been investigating several anomalies that have arisen since fitting a DRO to my Colly Master. (I posted a query regarding Spindle Bearing Adjustment)

So started checking motor for vibration, removed belts(2), found some…, removed pulley (TaperLok), ran with key still seated…, vibration, removed key…, vibration, noted VFD frequency readings, vibration seemed to be from 22Hz-39Hz, ran smoothish at other freqs including full speed 60Hz.

The motor is a Siemens 3ph 2 pole 2800rpm 2.2Kw/3Hp 220v/440v.

My question to the forum, is it the motor or the VFD settings.

As can be seen, I'm using a motor below the rated power of the VFD, would this need to be addressed?

Are there settings to accomplish this, I've tried the Frequency Carrier setting PD041, it came set at 3, tried 5,7,8 & 10, nothing changed the hunting noise, so returned to 3. (at the time didn't realise the motor was vibrating, thought it was the length of the belts(they are long A78))

I'm contemplating buying another motor(new this time), but the Siemens looked very new…,I bought 2 motors at the time 2nd hand, fitted the other to my Elliott miller, NO probs at all that I've noticed, I presume because the miller is very sturdy and a bit noisy itself, both motors run from the same VFD,..NOT at the same time, they are switched(photo)

Hope someone can help, it's driving me nuttts.

Bernard.

Bernard Wright.

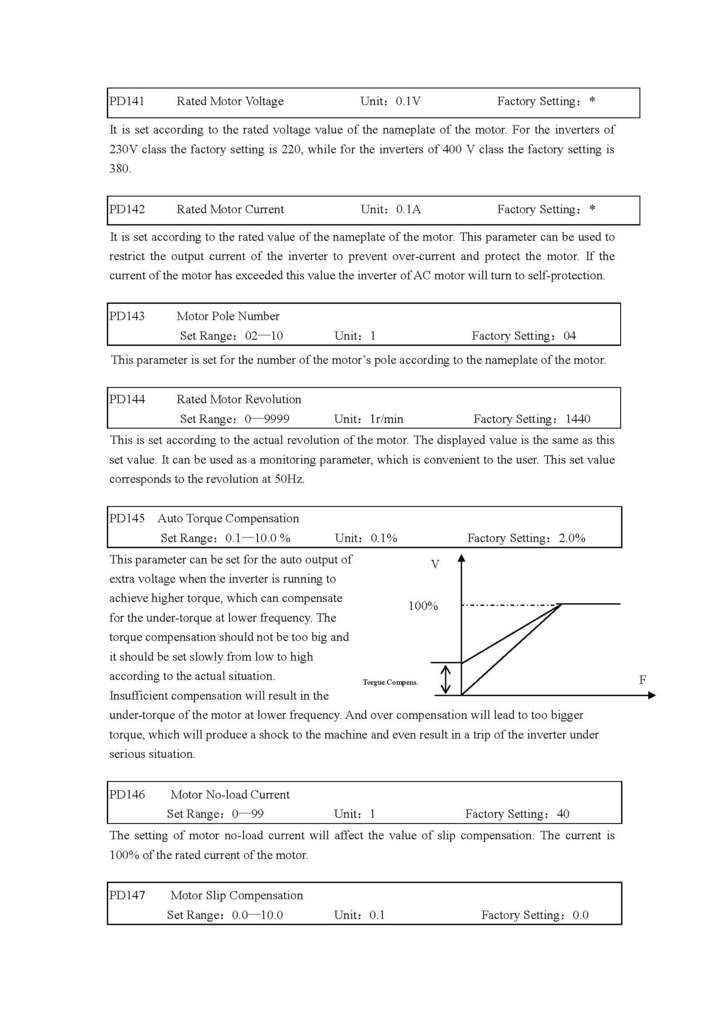

. Like you, I ran my motor on the default settings of 1440 and 4 poles for a while before realising they needed to be changed to 2880 2 pole, with no apparent change in how it performed. Also like you, my belts are long, maybe a bit longer than yours – you might want to check they are not too tight as that can cause them to whip just as much as if they are too slack. Also check the pulleys run concentrically and haven't suffered from corrosion in the vee – mine had in one spot because it had been stood idle for a long time.

. Like you, I ran my motor on the default settings of 1440 and 4 poles for a while before realising they needed to be changed to 2880 2 pole, with no apparent change in how it performed. Also like you, my belts are long, maybe a bit longer than yours – you might want to check they are not too tight as that can cause them to whip just as much as if they are too slack. Also check the pulleys run concentrically and haven't suffered from corrosion in the vee – mine had in one spot because it had been stood idle for a long time.