Posted by David Standing 1 on 23/07/2019 08:32:37:

Posted by Ketan Swali on 23/07/2019 06:38:25:

Most beginners WILL most likely break it.

Ketan at ARC

…

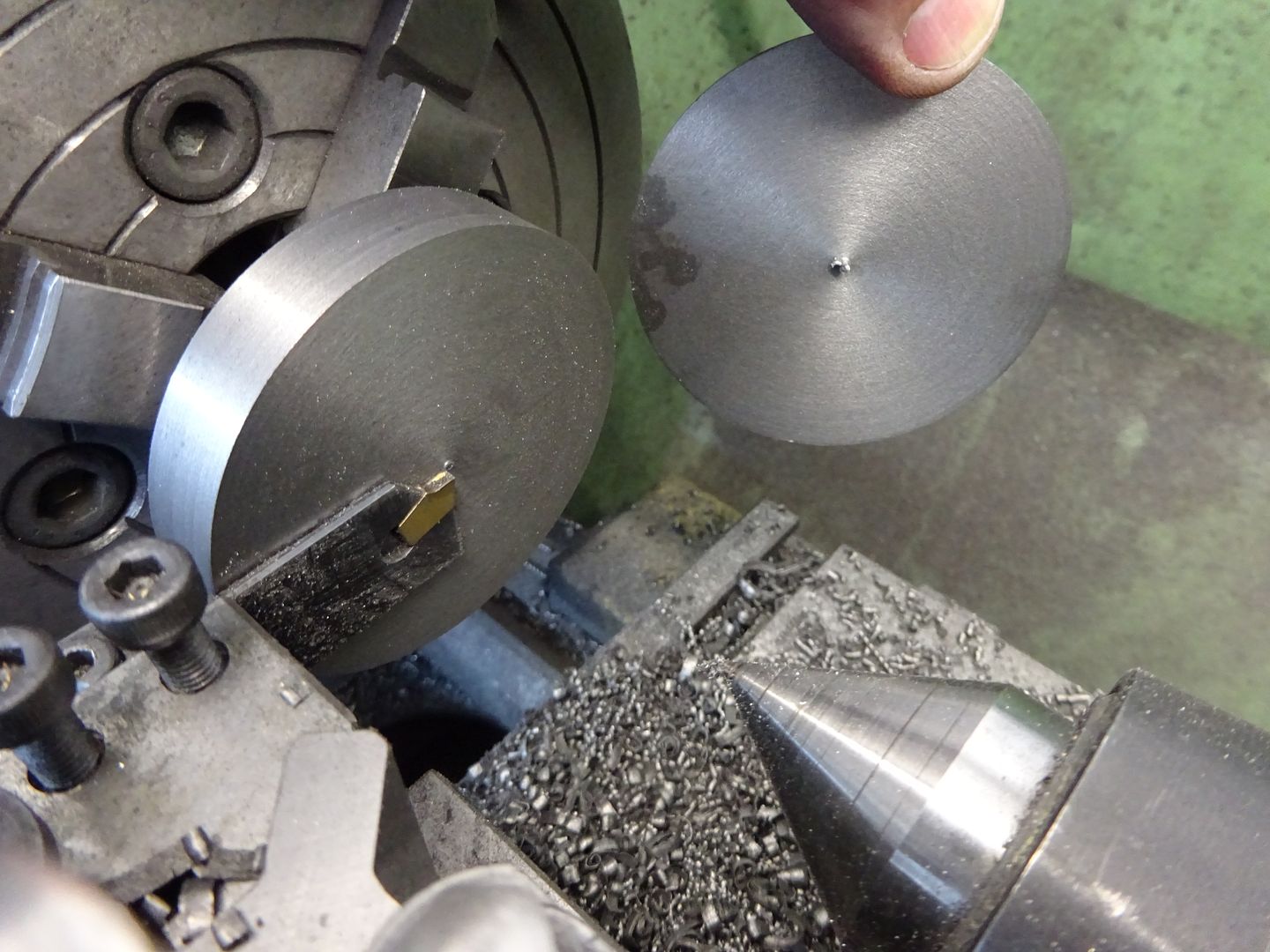

First time I used mine……I broke it

…

Me too! Still my preferred parting-off tool. Impressive when working well but not indestructible. Parting-off demands a lot of the lathe and the tool. Much easier to part-off on a heavy stiff machine than a bendy lightweight.

Two main problems I get.

- Swarf tends to jamb in the slot and the tool stops cutting, rubs and increases the unwanted forces on the machine that can displace the tool-tip. Aluminium causes most trouble because it's sticky and tends to weld, blunting the tool.

- The tool and maybe the whole saddle tend to bend slightly dropping the tool-tip and causing dig-ins. Anything that reduces rigidity is bad,, It can happen too fast for the operator to react and some are severe enough to damage the tool.

I've found all parting-off tools perform best with a steady feed when cutting correctly, which means getting the tool height, rpm and feed-rate right. Not too fast, not too slow, and definitely not jerky. Swarf clearance is vital. Proper lubrication helps, and the tool tip should be in good condition. Add it all together and it's not surprising parting-off goes wrong!

Parting off is a balancing act. I found a lot more skill was needed to do it successfully on a Mini-lathe than my WM280, and I imagine anything heavier would be easier again, mainly because big heavy lathes are less likely to flex enough to allow the tool-tip to dip into a dig-in.

What's really annoying is some lucky chaps don't have trouble parting-off. I suspect they have a steady hand, quick reactions and a natural feel for when tools are cutting correctly. The rest of us have to practice and experiment. I no longer expect disaster every time I part-off, but I'm not surprised that it goes wrong every so often.

The design of NCIH holders may be deliberately weak:

I suspect in commercial use where feed-rates are carefully calculated and automated, a dig-in means something really bad is wrong, and the tool is intended to break before the expensive CNC machine does.

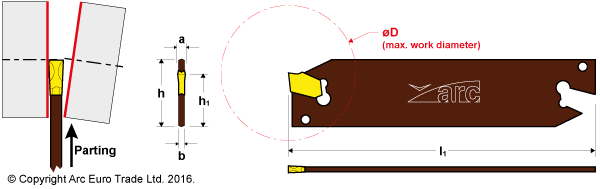

Still the best option for parting-off I've tried. Ketan's image shows the maximum parting-off diameter to be rather small: I invariably use the tool to take much deeper cuts than that!

Dave

Brian G.