Posted by John Haine on 07/10/2018 09:43:02:

Lathe or mill, surely irrelevant. Max diameter determined by max safe offset of the moving part in its dovetails. Personally I would not feel comfortable with it further than half the head diameter. Then you can add on the offset of the tool hole, or if you want a really big hole stick the tool out sideways in the transverse hole.

That does not make sense, first you say Max dia is determinded by the dovetails and then you say put the tool in the side to get a bigger dia which mean max dia is being determined by the tool.

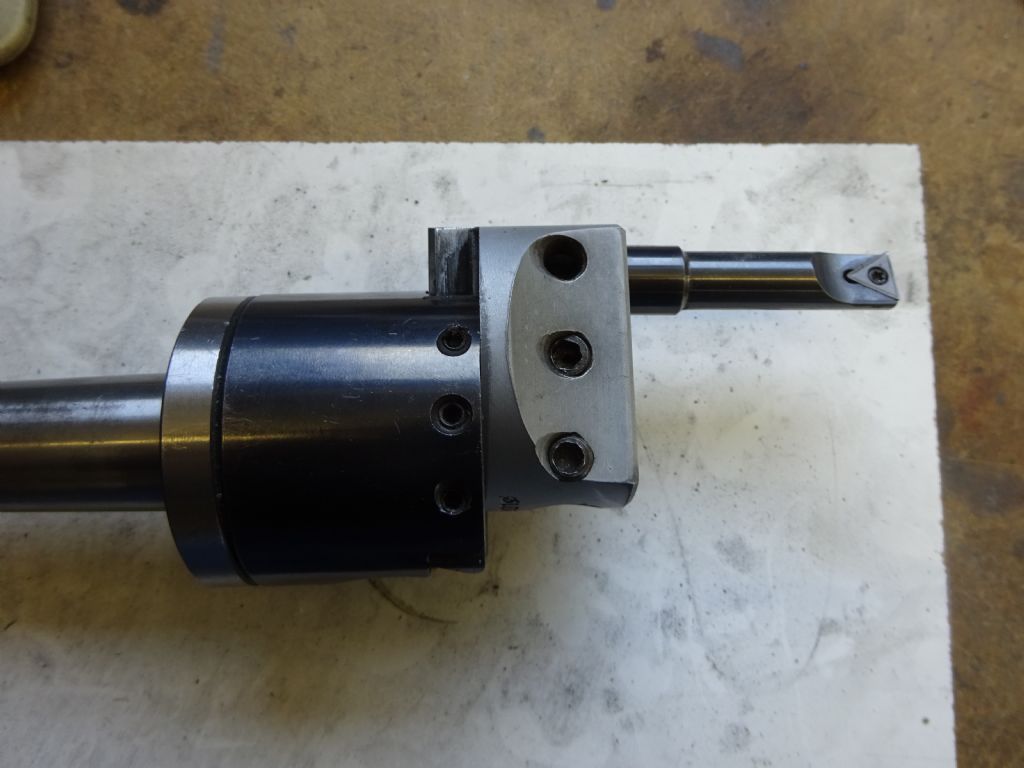

Even if using the end holes the type of tooling can be used to gain more diameter where length is needed, look at these two same offset of the head but 1+" increase in diameter

A boring head in the lathe is handy when you have a part that is too tall to stand vertically in the mill or simply don't have a mill when the part is again too big to swing plus you get to use the lathes power feed for a nice smooth bore as not many small mills have power to Z.

Edited By JasonB on 07/10/2018 10:35:34

Bazyle.

Bazyle.