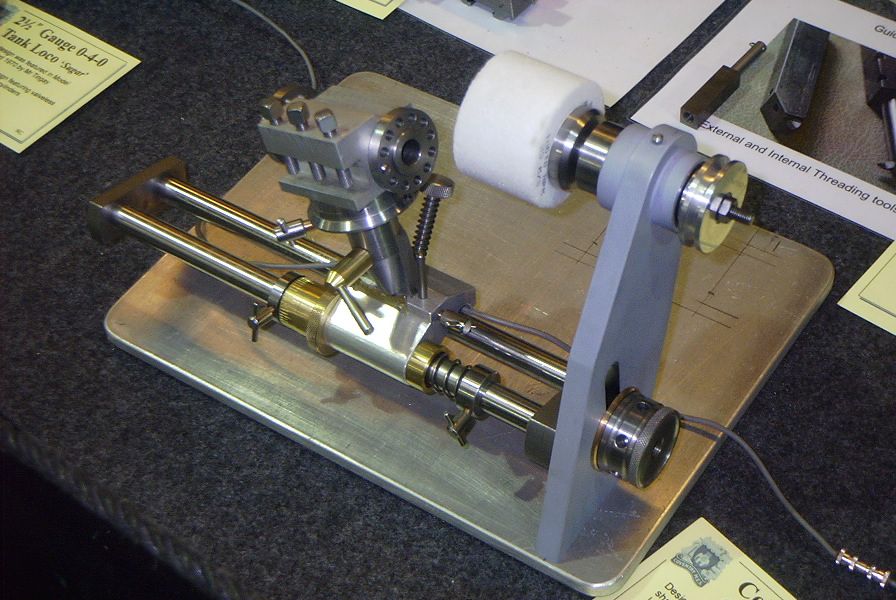

The Brookes T&C grinder design published in MEW April/May and June/July 1993 uses no castings and is said to be a strightforward build. As described it has no drill sharpening facilities but a four facet style using interlocking toast rack V-blocks to hold the drill looks easy enough to add. For a conical point one of the swing designs could be set up. These work well if the geometry is correct.

My main beef with all published designs is the assumption that infinite angle adjustment is both desirable and essential. Realistically the ordinary worker needs very few angles, almost certainly less than 10, so infinite adjustablitily just makes more work and opens up the probability of errors. A few fixed angles also has the advantage that the tool works just the same after each re-sharpening whereas successive nearly the same means you may have to keep re-learning how to get the best out of it. Really sharp but maybe not quite optimum angle always beats book angle but such a pain to regrind that it has to be really blunt before it comes out!

Somewhere in my pile of abandoned back of envelope sketches is a basic layout for a system using stacked pivoting blocks and various sized pins to set the angles. Never really went anywhere because I couldn't see a decent way of doing repeatable and accurate nose radii on lathe. Then I got a Clarkson. Angle templates are theoretically good but no substitute for rapid locking to fixed values. My design also took a fixed grind at each tool sweep so you knew eaxaclty what was happening.

Clive.

norman valentine.

Works a lot like Stewart's , I guess.

Works a lot like Stewart's , I guess.