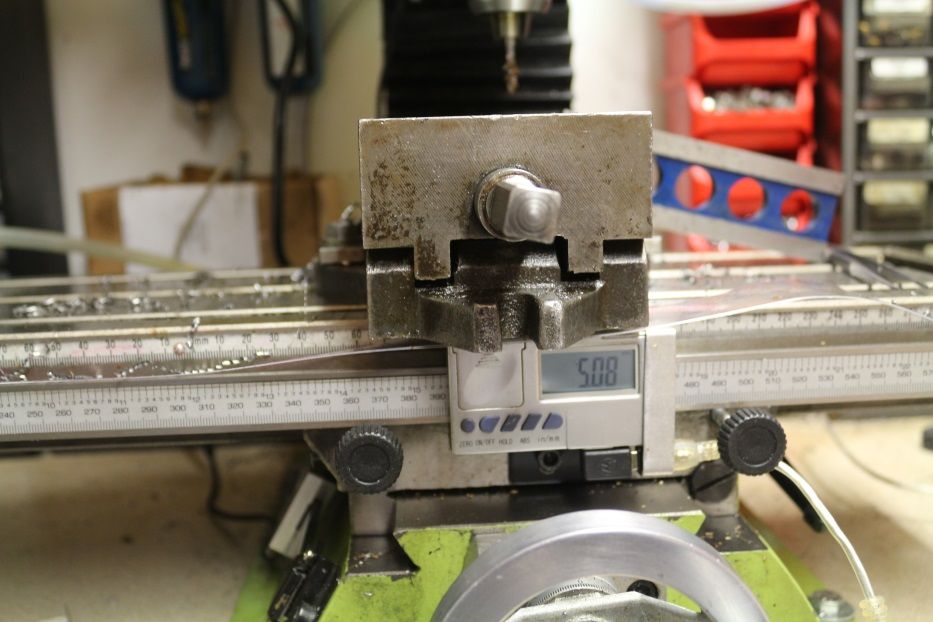

I have always had problems with the cheap WARCO two axis DRO on my WM 16 mill but of late it has become much worse – like unusable! Setting a datum point using x0 – y0 and without even moving the x and y axis I can – with the machine plugged in – press "ON" and "OFF" repeatedly while watching the readout. Invariably and within the space of six cycles either X or Y will loose its zero reading and display a random measurement up to 30mm or so out of kilter. Sometimes BOTH axis change at the same time. One thing remains constant though, the problem only manifests itself when pressing the "OFF" button – never the "ON".

I suspected some sort of "noise" problem so I have dispensed with the original USB mini B leads and fitted heavier duty shielded leads keeping them as short as possible but the problem persists. The scales are squeaky clean and the calliper readouts, unlike the main display, remain accurate. I tried connecting an earth lead to the central screw on the control panel marked with an earth symbol and the other end to the mill casting and that makes no difference either. Finally I relocated the readout a couple of feet away from the machine – still the problem is there. Having googled at length I can see that this is quite a common problem with these budget systems but I appreciate that with all the variables a common fix is probably not possible. However, I live in hope! I would add that the electrical installation in my workshop was carried out by a pro electrician this year and is certificated.

That is as far as I can go with my very limited electrical knowledge unless some kind soul can advise me. In the meantime I am back to using the graduated hand wheels.

Rik

Rik Shaw.

Rik Shaw.

than as suggested use a different mains outlet or if possible power it temporarily from a battery.

than as suggested use a different mains outlet or if possible power it temporarily from a battery.