Hi Lee,

As someone who has made a Boxhill boiler recently in 5"g perhaps I might add a few comments.

(Mine differs from the original what I consider to be defective design by Martin Evans).

The Martin Evans design was during his early 'experimental' period when he really pushed the boundaries as to what had been acceptable before for boilers hence no crown stays fixed to the outer firebox wrapper etc. The inner firebox wrapper is far too thin for my liking. The water gauge bottom bush is far too low. None of the backhead fittings are in the right place for fullsize.

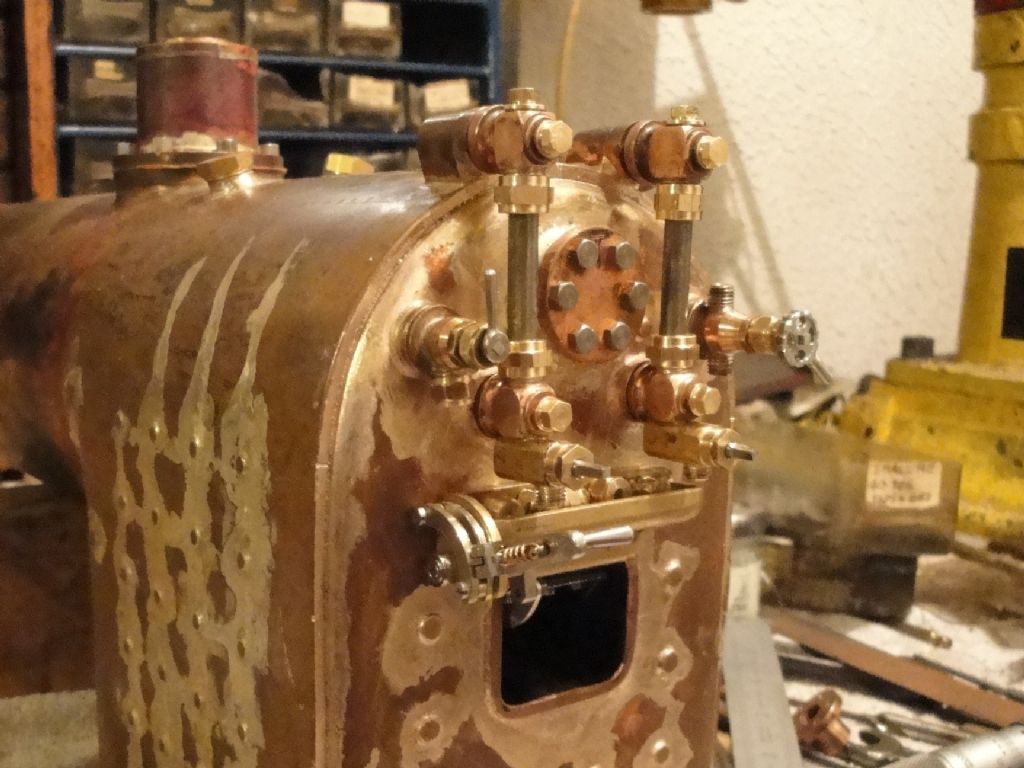

There are lots of pics in my albums of my own boiler build with correct oblong firehole ring as per original and 2 water gauges.

For TIG welding the whole boiler design needs looking at and redesigning to give the proper joints required for TIG welds plus the correct grade of copper needs using. This will require almost certainly a joint on the barrel longitudinally as the barrel will have to be made out of sheet copper of deoxidised sheet.

This barrel joint might conflict with the very close weighshaft of the valve gear.

I could only get C101 copper tube for my boiler barrel of 3 3/4" dia, which also was split to form the firebox with only an outer firebox extension added on the right hand side (Evans' design called for an extension on each side).

I also fitted in 2 extra ordinary flues.

Mine has the correct to prototype oblong firebox hole ring and correct Stroudley firehole door.

I think a much neater boiler is produced by silver soldering than TIG, which in the case of Boxhill might be quite important. For example in fullsize there is a generous radius on the backhead flange not followed by Martin Evans but which I endeavoured to replicate. This would not be possible I suggest with a TIG welded boiler.

It is quite a simple boiler to build as a silver soldered job.

I do not disagree with any of the previous posters comments.

Cheers,

Julian

Edited By julian atkins on 28/01/2017 23:31:30

julian atkins.