Alec,

Please forgive me if I'm 'teaching Grannie how to suck eggs'!

Starting from the lathe mandrel:

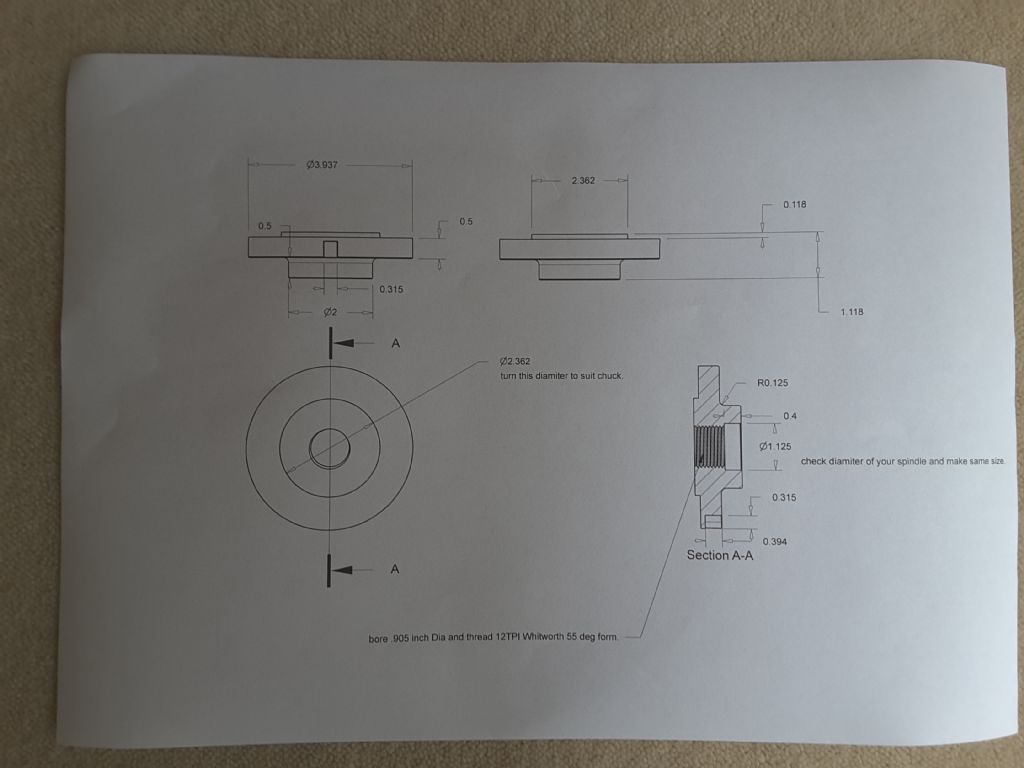

The chuck back-plate should be located radially by the register on the lathe mandrel nose.

The chuck should be located radially on the back-plate by the male register you machine onto the face of the back-plate so that it is a precise fit into the female register on the rear face of the actual chuck.

The fixing screws are responsible for securing the chuck to the back-plate to prevent relative rotation or axial play: they should play no part in radial location and so can be a comfortable clearance fit in the holes in the chuck.

5/16" BSF or M8 sound about right to me for an M-type or an ML7 machine. Choice of thread depends upon what size cap-heads you can most easily obtain and what taps you have.

Machining of the face of the back-plate should include a face skim (outboard of the central register ) so that the chuck will seat so its axis and the lathe mandrel axis are parallel, i.e. no relative squint. The register on the back-plate should almost, but not quite, fill the female register in the back of the chuck, it should not bottom-out.

Best regards,

Swarf, Mostly!

P.S.: you don't need to make your own fixing screws – eBay is full of sellers offering all sizes and lengths and thread types of cap-head screws.

Swarf, Mostly!

P.P.S.: when I wrote the above, I was assuming we were discussing a three-jaw self-centring chuck. I have now tried Alec's link and see we're actually discussing ain independent four-jaw chuck. I think virtually all I wrote is still valid.

Swarf, Mostly!

Edited By Swarf, Mostly! on 09/07/2022 13:03:02

Edited By Swarf, Mostly! on 09/07/2022 13:08:38

David George 1.

David George 1.