Hi Nick,

What is making that high pitch noise in the video's ?

Is that why you want the motor turned off ? or is there some other reason for the constant start stop of the motor?

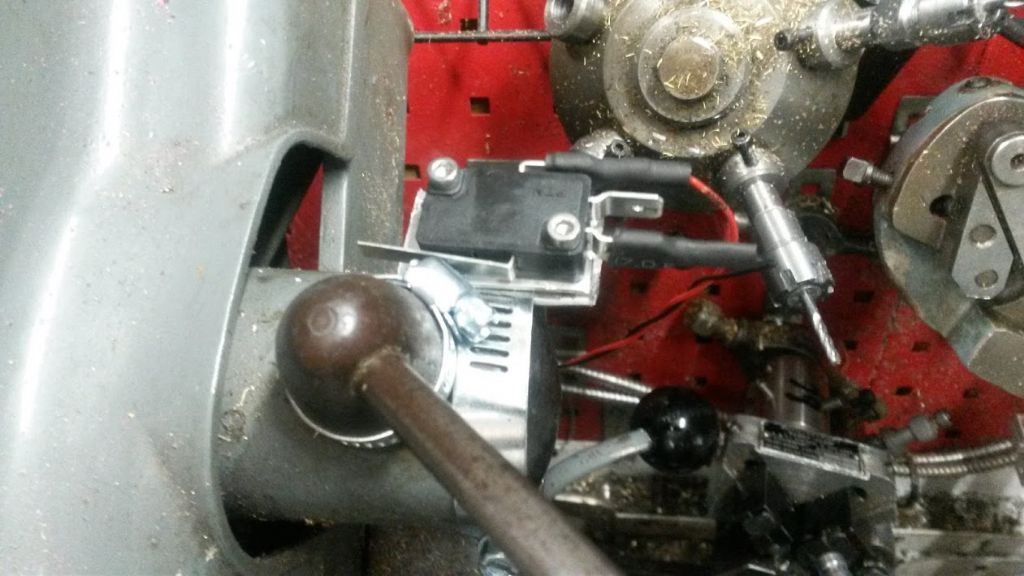

Yeah the forward reverse and the breaking rate control and the acceleration rate control is just great with a VFD, and the programmed settings that can be made really is awesome. Mine is just box on the wall above the lathe, with the original on off forward reverse switch, is just doing the remote feed off the controller. So the original switch does on forwards/ Off/ On Reverse. The variable aspect is on the adjuster pot mounted on the front cover of the box. Then I have a micro switch that I attach with a magnet , that when activated, turns off the forward control. Then when I switch to reverse, it starts up and runs back. I use this for my thread depth stop when screw cutting inside parts. And now also use it for outer threads as well. Takes away the guess of when to stop. I don't run my S7any quicker than the 60hz in low drive top belt, so something like 700 rpm is the max I run. But the spindle is adjusted to give me the lowest possible error of roundness and spindle movement for trimming my pistons.

Nick Hulme.