I am trying to compile advice for the novice home machinist. While I have an ML7, and I know that such a fitting is difficult, others are likely to be easier (as indeed is the EMCO illustrated by Thor above – thanks).

So, I would like advice about how the ML problem has been solved, as well as a view about other lathes which are easy or difficult in this regard.

Yes, Morse taper collets and collet holders and anything else which is pulled into a taper (including, I suppose, lathes which have similar tapers such as B&S).

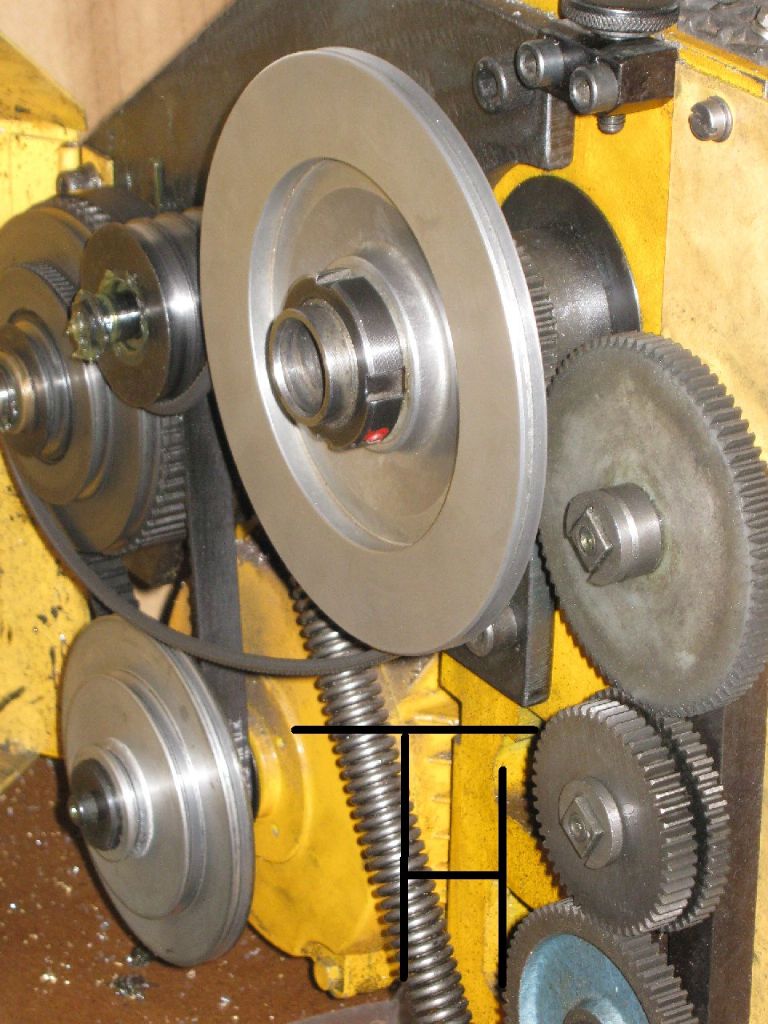

And regarding the Thor machine, it would be a fairly easy matter to make a sleeve fitting to go in place of his big aluminium pulley, extending to the left to hold the collar of a drawbar, and using the slotted nut (and a tube-spanner) to hold it in place. Or, a conical tube bolted to the pulley but then doing the same job. If you see what I mean.

What a shame we are not all sitting together, with a stock of old envelopes, it would be much easier to explain, then.

Regards, Tim

Edited By Tim Stevens on 17/01/2016 15:35:38

Tim Stevens.