Hi Roger.

The design of the carraige interlocks is very simple and quite clever, and can work perfectly well. The only problem with it I have encounted on these machines is that the factory responsible for the assembly of these lathes sometimes use whatever piece of grotty off cut they find to make the flat bar lever at the back of the apron that locks the feeds.

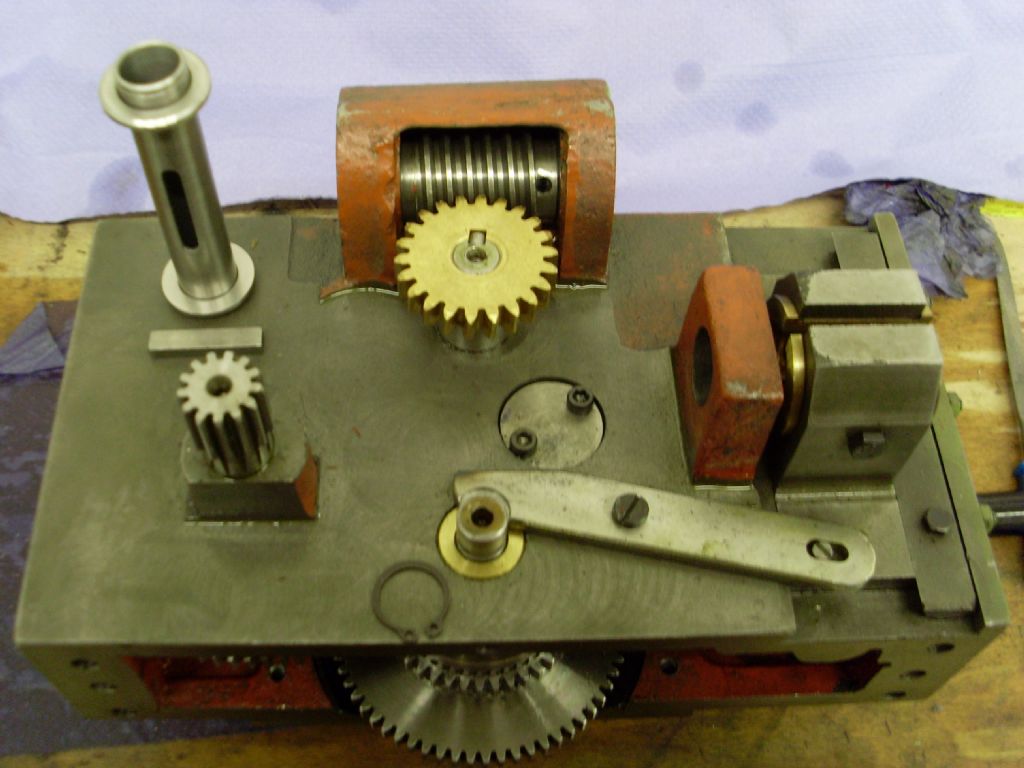

On my lathe that interlocking lever was made from a piece of very battered, bent and corroded scrap. The corner that engages in the sliding shaft groove was badly formed with a hand file. So it worked, but only just, the lever in the photo is a new replacement I made.

It's a good solid system. There is a sliding shaft that sticks out the front of the apron and meshes with the feed control lever, the control lever slides the shaft in and out. This shaft passes right through the apron and internal gears and sticks out the back. When the power feed control lever is in neutral the deep groove machined into this sliding shaft is inline with the interlock flat bar lever at the back of the apron, the other end of the flat bar is attached to one of the leadscrew half nuts. This allows the half nuts to be closed because one end of the flat bar swings into the shafts groove, this then prevents the power feeds from being simultaneously engaged because the shaft is now prevented from sliding in or out.

When power feeds are engaged this slides the shaft in or out so that the groove in the shaft is no longer inline with the interlock lever, so this now prevents the half nuts from being engaged because the lever can't move far enough, it just buts against the shafts outer diameter.

Edited By Lathejack on 02/01/2016 13:29:58

Edited By Lathejack on 02/01/2016 13:33:16

ega.