Why reverse a lathes direction?

Why reverse a lathes direction?

- This topic has 71 replies, 27 voices, and was last updated 4 September 2015 at 09:22 by

Martin Kyte.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Depth of cut cowells me90

- Alternatives for a DRO display change

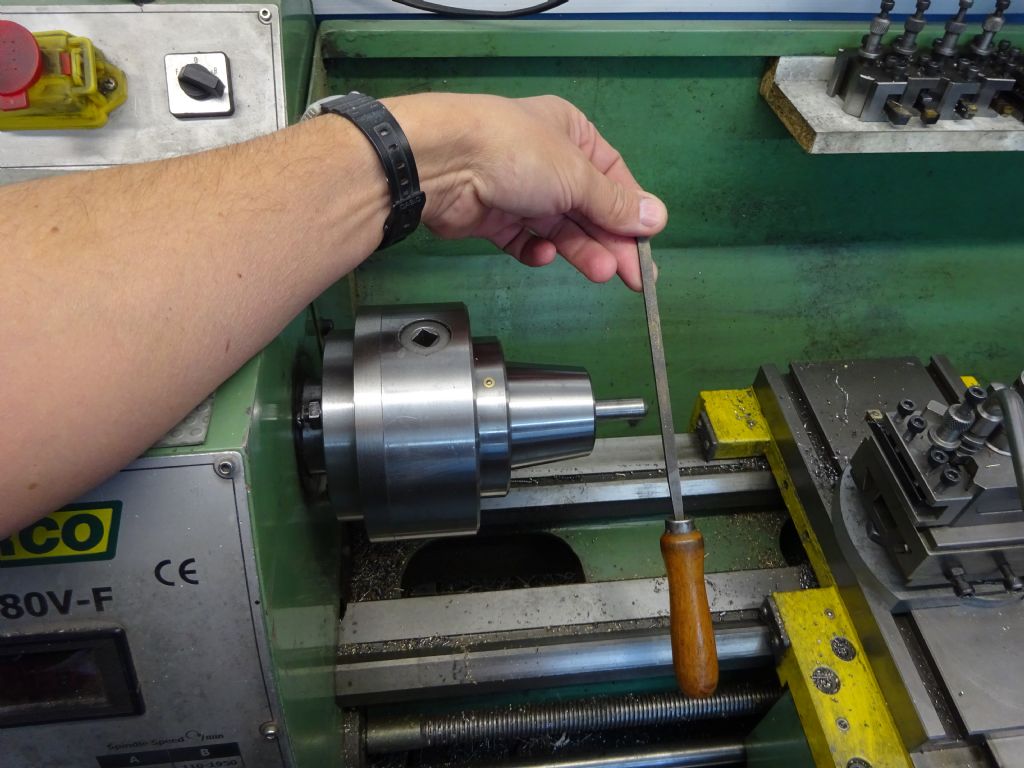

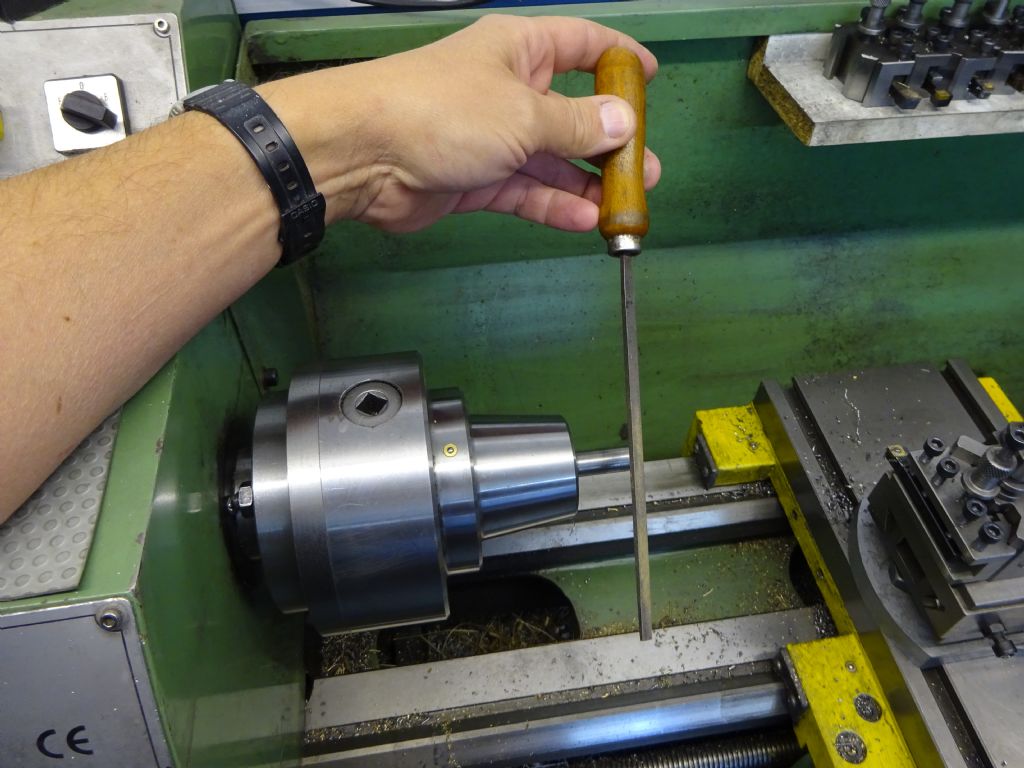

- 100mm 4 jaw chuck servicing

- MD65 leadscrew cross-slide stuck in nut

- MIG Welder Won’t Weld

- CNC Coolant

- Hi I’m a newcomer

- How to balance a cup grinding wheel

- Help recommend a milling machine?

- Beginner with newly bought lathe – many questions