Peter also asked my via one of my Videos on Yutube but I will reply here so that I can add some photos and it may be of use to others wanting to put a big vice on a small mill.

As others here I suggested an 80mm vice for this Mini-mill and these following photos illustrate some of the reasons why I'm using the SX2.7 with a table of 595 x 140 which is larger than the mini-mill's table at 460 x 112.

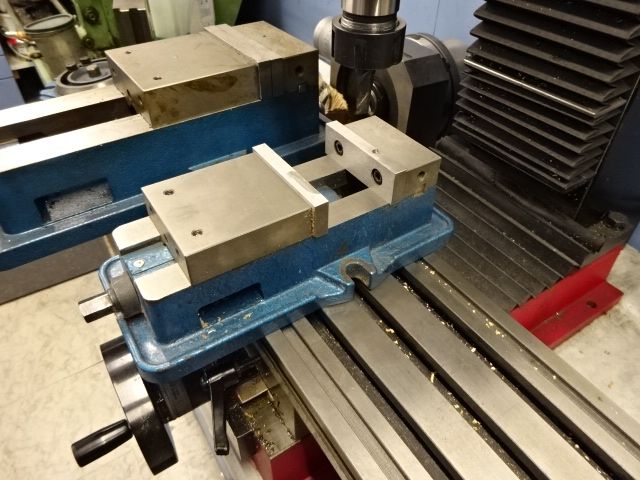

Firstly a shot of a 100mm versatile vice from ARC without it's swivel base, not that as the size of a vice goes up the fixed jaw tends to be further back from the mounting lugs so if a cutter of modest size (12mm in photos) is to clear the back of any work in the vice then it will have to be mounted to the fromt tee slot. This makes it almost impossible to see the handwheel let alone the dial on a non DRO equiped machine.

The next size down is the 80mm Versatile which can be mounted to the central tee slot which gives a better view of the handwheel and you can also see the dial

Side by side comparison

Peter did say he was thinking of the Radial vice from ARC which probably does have a slightly smaller footprint than the versatile due to not having the "lip" all round the base but tee slot position would still come into it and they don't open as far.

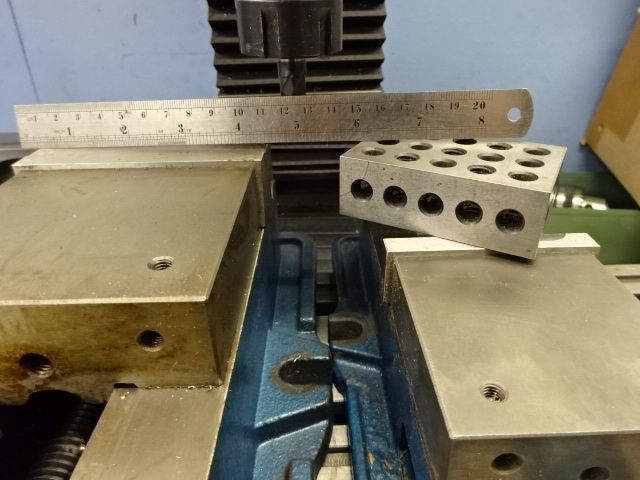

The other thing to think about on the very small mills when looking at vices is their height, here you can see that the top of the 100mm vice's jaws are just under 25mm further above the table than those of the 80mm eating into valuable head room

Finally on a safety note I managed to drop the 100mm vice while taking these photos as it is just about hovering when bolt holes are over that nearest tee slot and that is with the jaws closed, glad I had steel caps on at the time even though I did manage to jump back in time so it only dinged the vinyl tile.

old mart.