it felt right strange for me.

If I am not caving on a Saturday I usually spend the day at the W&DMES track and club-room, but they are out of reach behind locked gates (school grounds) for the duration even before any decision by the society itself.

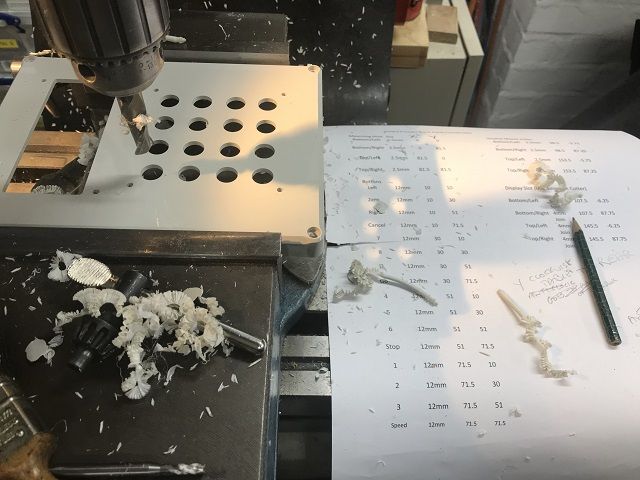

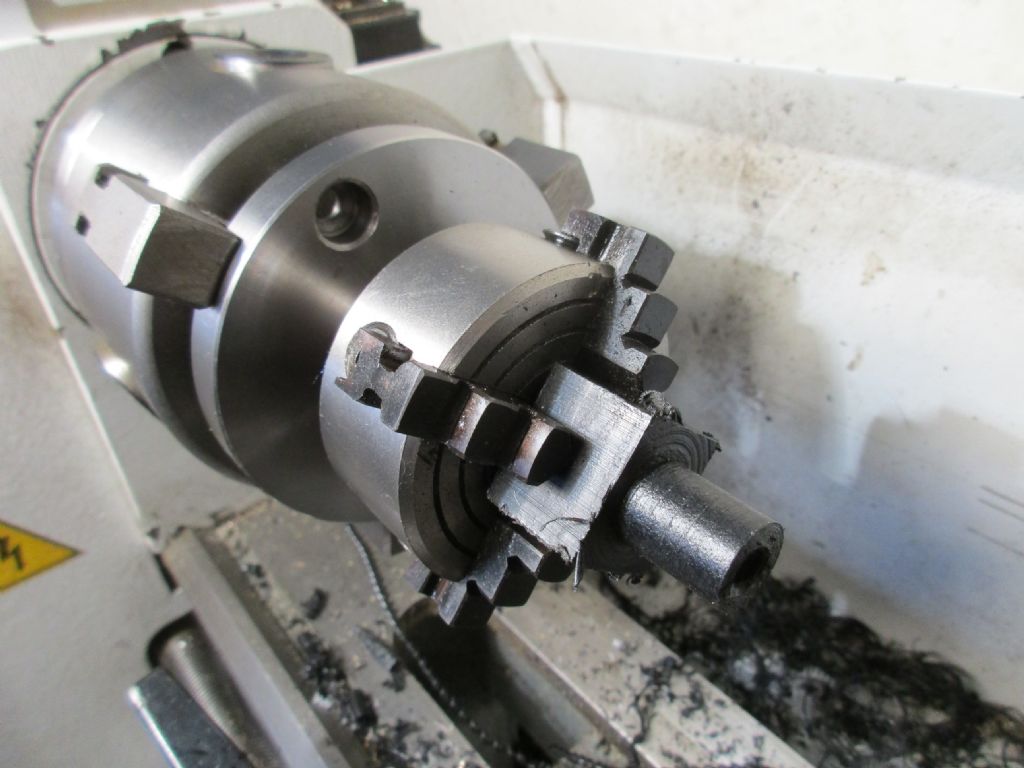

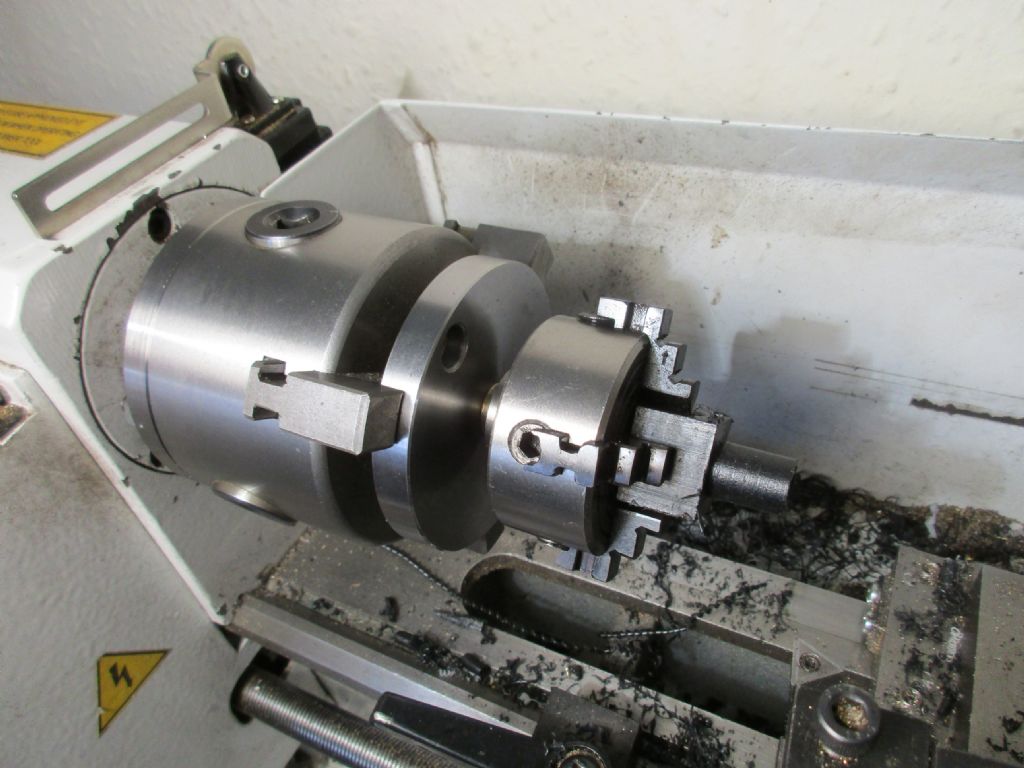

Ah well, no excuse for not cutting steel, and after my all-too-usual round of mis-measurements and confusing sides on handed pairs, I completed much of fabricating the boiler-mounts for my steam-wagon.

Now, when I say "caving" it's actually a long-term "digging" project our small team has, to work a way through a very deep mass of limestone and conglomerate boulders to find the cave we believe and hope lies beyond – 150ft deep so far and no sign of breakthrough yet. We generally go underground for 3- 4 hours then retreat, mid-afternoon, to the Club HQ for showers, Tea and Cakes.

Clearly, whilst any outdoor pursuits or even meeting the team socially are presently out of the question, one still has to uphold the niceties, so naturally, I retreated mid-afternoon to the domestic HQ for Tea and Cakes.

Helps me remember it's Saturday.

Only afterwards, I did climb back into the overalls and return to the fray, stopping finally when it became too dusky and cold to work on something standing outside the workshop.

Whilst partaking of the tea & cakes, I enjoyed the play on the radio – a dramatisation of Jules Verne's The Mysterious Island, the sequel I had not previously known he'd written, to 20 000 Leagues Under The Sea.

Nigel Graham 2.